HOME / NEWS / Industry News / The Ultimate Guide to Round Head Foam Swabs: Uses, Benefits, and Selection

Understanding the Design and Material of Round Head Foam Swabs

Round head foam swabs are specialized cleaning and application tools designed for precision tasks. Their unique construction sets them apart from traditional cotton swabs, making them indispensable in various industries, from electronics to healthcare. The core of their design lies in the combination of a soft, absorbent foam head and a sturdy, often plastic, handle. This section delves into the specifics of their design and the materials commonly used.

The Anatomy of a High-Performance Foam Swab

The effectiveness of a round head foam swab is determined by its individual components. Each part is engineered to contribute to the tool's overall functionality and reliability for delicate operations.

Foam Head Characteristics

The foam head is the most critical component. It is typically made from polyurethane or cellulose due to their excellent absorption and low-linting properties. The round shape is not arbitrary; it allows for omnidirectional cleaning and application without sharp edges that could cause damage. For instance, when compared to a pointed foam tip, a round head foam swab for precision cleaning offers a larger surface area for applying solvents while still being able to access tight spaces through a gentle rolling motion, whereas a pointed tip might concentrate pressure and increase the risk of damaging a sensitive component.

Key characteristics of the foam head include:

- Porosity: Determines the liquid holding capacity.

- Density: Affects the softness and abrasiveness.

- Chemical Compatibility: Resistance to various solvents and reagents.

Handle and Stem Design

The handle, or stem, provides the structural integrity needed for control. Plastic stems are lightweight and resistant to many chemicals, making them a popular choice. The length of the stem dictates the reach and leverage a user has, which is crucial for applications inside deep cavities or complex assemblies. A well-designed stem must also securely anchor the foam head to prevent detachment during use, which is a common failure point in inferior products.

Key Applications and Industries for Foam Swabs

The versatility of round head foam swabs is demonstrated by their wide range of applications. They are not simple cotton bud replacements but are instead engineered solutions for specific, often critical, tasks.

Critical Role in Electronics Manufacturing and Repair

In the electronics industry, the absence of lint and static is paramount. anti-static round head foam swabs are specifically manufactured to dissipate electrostatic charges, preventing damage to sensitive microcircuits, printed circuit boards (PCBs), and other electronic components. They are the tool of choice for applying fluxes, cleaning connectors, and removing contaminants from optical lenses and lasers. Using a standard swab in these scenarios could introduce fibers that cause short circuits or leave behind static that attracts more dust.

Essential Tools in Medical and Laboratory Settings

Precision and sterility are non-negotiable in medical and lab environments. Here, foam swabs are used for applying antiseptics, collecting samples, and cleaning intricate surgical instruments. Their ability to absorb and release liquids in a controlled manner makes them ideal for applying reagents in diagnostic tests or cleaning sensitive optical equipment like microscopes and spectrophotometers. The foam's consistency ensures that it does not scratch delicate surfaces, which is vital for maintaining the integrity of expensive lab equipment.

Selecting the Right Swab for Your Task

With a myriad of options available, selecting the appropriate round head foam swab is crucial for achieving optimal results. The choice depends on a careful analysis of the task's requirements.

Material Compatibility: Foam and Solvent Interaction

Not all foam materials are compatible with all chemicals. Using a swab made from a foam that degrades when exposed to a specific solvent can lead to contamination and task failure. For example, polyurethane foam is generally resistant to alcohols and mild solvents, making it suitable for many cleaning tasks. However, for stronger acids or ketones, a specialized chemically-resistant foam is necessary. This is why a chemical resistant round foam swab is a distinct category, designed to maintain its structural integrity when exposed to aggressive substances that would dissolve a standard foam head.

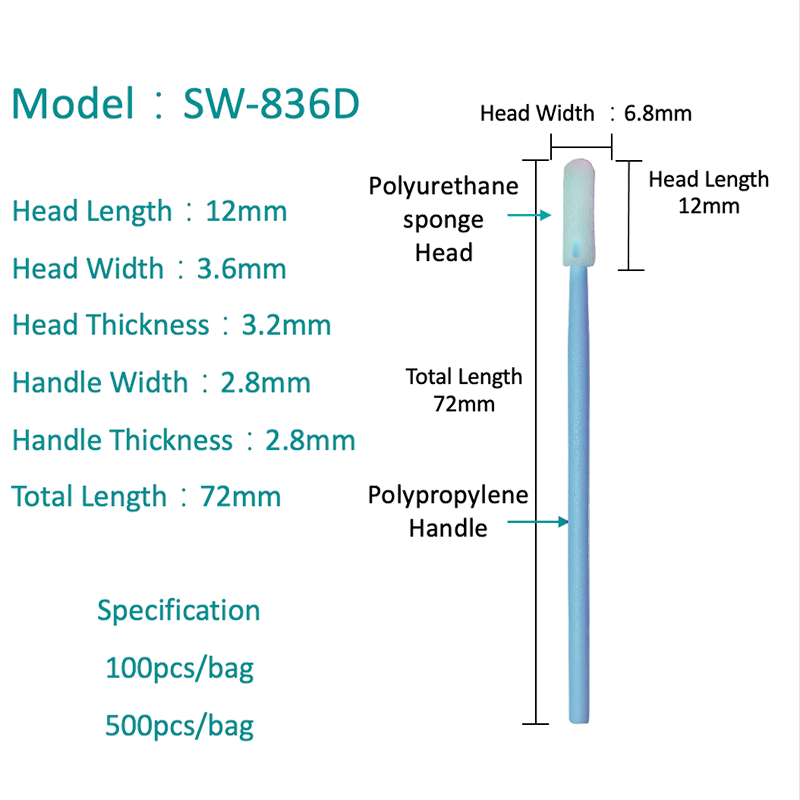

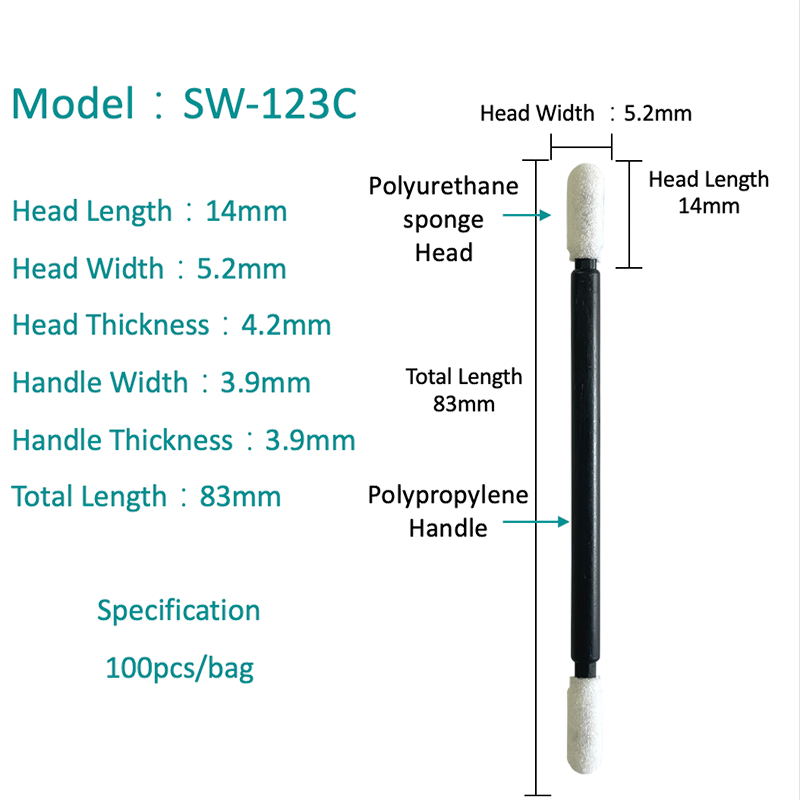

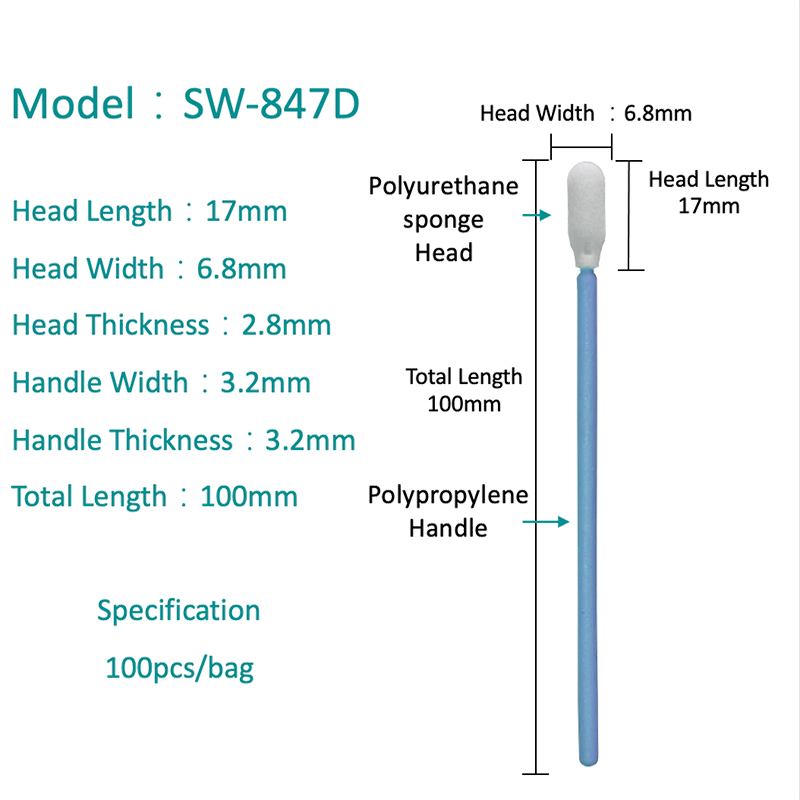

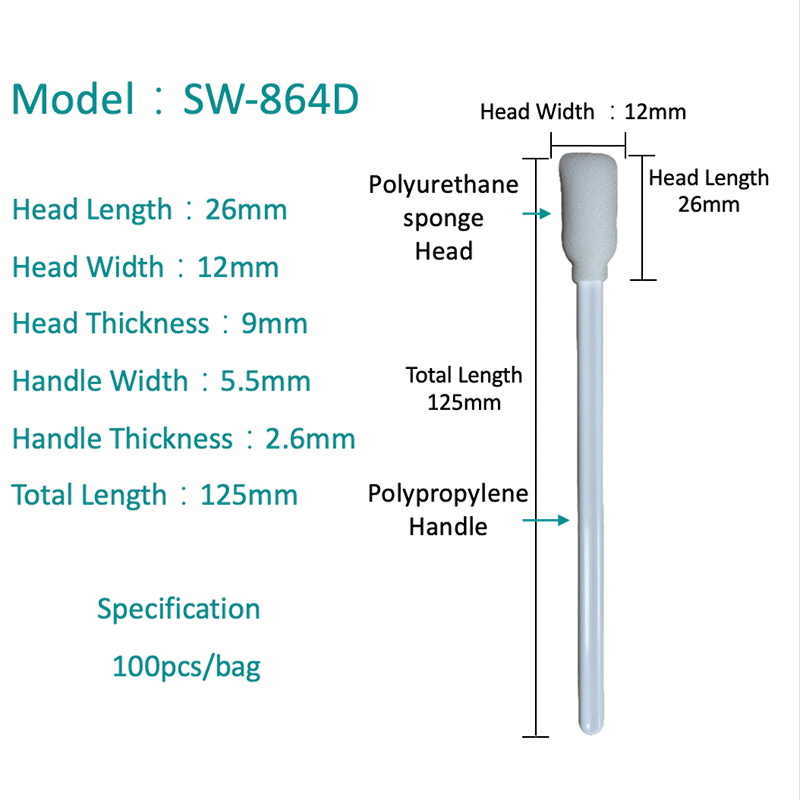

Assessing Size and Density for the Job

The physical dimensions of the swab head must match the application area. A large head is inefficient for a small component, while a small head would be overly time-consuming for cleaning a large surface. Furthermore, density matters. A low-density foam is very soft and highly absorbent, perfect for applying a lot of liquid gently. A high-density foam is firmer, providing more scrubbing power for removing stubborn contaminants without falling apart. For detailed work on valuable equipment, many professionals seek out the best round head foam swabs for delicate surfaces, which are specifically engineered with an ultra-soft, low-abrasion foam to eliminate any risk of scratching.

The following table contrasts key selection criteria:

| Task Requirement | Recommended Foam Type | Swab Head Size | Stem Type |

|---|---|---|---|

| Applying solvent to a large area | Low-density, open-cell polyurethane | Large (e.g., 15mm) | Long plastic stem for reach |

| Scrubbing hardened flux off a PCB | High-density, abrasive-resistant foam | Medium (e.g., 9mm) | Short, sturdy stem for control |

| Cleaning optical lenses | Ultra-soft, lint-free cellulose | Small (e.g., 6mm) | Medium plastic or paper stem |

Advantages Over Alternative Cleaning Tools

While other tools exist for application and cleaning, round head foam swabs offer a unique set of advantages that make them superior for precision tasks.

Superiority to Cotton Swabs

The most common alternative is the cotton swab. However, foam swabs outperform them in several key areas. Cotton swabs are prone to shedding micro-fibers, which can cause contamination in cleanrooms, on electronics, or in medical applications. The foam head is monolithic and, when properly manufactured, is virtually lint-free. Furthermore, foam has a higher absorbency and liquid retention capacity than cotton, allowing for more efficient application and less dripping. The controlled release of liquid from a foam swab prevents pooling, which is especially important when working with sensitive materials that can be damaged by excess fluid.

Benefits Compared to Wipes and Tissues

Wipes and tissues are excellent for large, flat surfaces but lack precision. A lint free round head foam applicator can access crevices, holes, and uneven surfaces that a wipe cannot reach. The swab's handle provides direct control and prevents the user's hand from contacting the surface or the chemical, enhancing safety and preventing oils from skin from contaminating the work area. For tasks requiring a dabbing or stippling motion, such as applying a dye or adhesive to a specific spot, the foam swab is the unequivocal tool of choice due to its pinpoint accuracy.

Proper Usage and Handling Techniques

To maximize the effectiveness and lifespan of round head foam swabs, correct usage and handling are essential. Improper techniques can lead to wasted material, incomplete cleaning, or even damage.

Effective Methods for Cleaning and Application

The technique should be tailored to the goal. For general cleaning, the recommended method is to saturate the foam head with the appropriate solvent and then gently roll it across the surface. This rolling action uses the entire surface area of the swab and helps to lift and absorb contaminants. Avoid pressing too hard, as this can force debris deeper into the surface or cause the foam to tear. For application tasks, such as applying a lubricant or adhesive, a light dabbing or swirling motion is often more effective to ensure an even, controlled coat.

Important Safety and Storage Considerations

Always inspect swabs before use, especially if they are sold as sterile. Do not use a swab if the packaging is compromised. When working with volatile or hazardous chemicals, ensure the foam material is compatible to avoid chemical reactions. After use, dispose of the swab according to the rules for the chemicals it has contacted. For storage, keep unopened packages in a cool, dry place away from direct sunlight to prevent the foam from degrading over time. For critical applications, it is advisable to use a disposable round head foam swab to guarantee sterility and prevent cross-contamination between uses, which is a fundamental practice in medical and laboratory environments.

English

English  中文简体

中文简体