HOME / NEWS / Industry News / Industrial Sterile PP Cleaning Swabs: Buy Wholesale for Labs & Factories

Essential Tools for Precision Cleaning: Understanding Sterile PP Swabs

In environments where contamination control is paramount, the selection of cleaning tools is not merely a matter of convenience but a critical component of operational integrity. Industrial sterile polypropylene (PP) cleaning swabs have emerged as a fundamental instrument for a wide array of applications, from delicate laboratory work to rigorous factory maintenance. These swabs are specifically engineered to meet the highest standards of purity and performance. The polypropylene handle provides exceptional chemical resistance, ensuring it does not react with or leach contaminants into sensitive solvents or solutions. Coupled with a meticulously chosen absorbent tip material, these swabs offer superior cleaning and sampling capabilities without introducing foreign particles, fibers, or biological contaminants. For procurement specialists and facility managers, understanding the nuanced benefits and specific use-cases of these swabs is the first step toward optimizing cleaning protocols, reducing cross-contamination risks, and ensuring product quality. Purchasing these essential items wholesale is not just an economic decision; it's a strategic move to guarantee a consistent, reliable supply of a critical consumable, thereby safeguarding production schedules and research outcomes from unforeseen disruptions. This section delves into the core attributes that make sterile PP swabs indispensable in modern industrial and scientific settings.

Key Applications for Industrial Sterile Swabs

The utility of industrial sterile PP cleaning swabs spans a remarkably diverse range of sectors. Their design caters to tasks that demand precision, absorbency, and an absolute absence of contaminants.

Laboratory and Life Sciences

In the controlled environments of laboratories, even microscopic contamination can compromise years of research or render a batch of pharmaceuticals unusable. Sterile PP swabs are the tool of choice for a multitude of critical tasks.

- Equipment Maintenance and Decontamination: Used for meticulously cleaning optical lenses, spectrophotometer cuvettes, and other sensitive instrument parts where lint or chemical residue would cause significant errors in measurement.

- Sample Collection and Application: Essential for applying reagents in precise locations on diagnostic test strips or for collecting biological samples from surfaces for subsequent analysis without introducing external DNA or enzymes.

- Cell Culture and Microbiology: Employed for gentle cleaning around biosafety cabinets and incubators, and for applying disinfectants to specific areas without risking spore or viral contamination from the cleaning tool itself.

Electronics and Semiconductor Manufacturing

The production of electronics, particularly semiconductors, requires an environment virtually free of particulate and ionic contamination. Here, the integrity of every component is non-negotiable.

- Circuit Board Cleaning: Effectively removing flux residues, dust, and other particulates from printed circuit boards (PCBs) before conformal coating or final assembly. The static-dissipative properties of some PP swabs are crucial in preventing electrostatic discharge (ESD) damage.

- Disk Drive and Optical Component Assembly: Used for precision cleaning of read/write heads, laser lenses, and fiber optic connectors where a single speck of dust can lead to device failure.

- Contamination Control Monitoring: Acting as a tool for validation and monitoring, swabs are used to sample surfaces for particulate contamination as part of a facility's overall quality assurance program.

Medical Device and Aerospace Assembly

Industries governed by stringent regulatory standards, such as medical device manufacturing and aerospace, rely on sterile swabs to meet cleanliness specifications.

- Pre-Assembly Cleaning: Ensuring that components for implantable medical devices or sensitive aerospace instrumentation are free of oils, particulates, and manufacturing residues that could impair function or safety.

- Adhesive and Coating Application: Providing a controlled method for applying specialized adhesives, lubricants, or coatings to small, confined areas during the assembly process.

Advantages of Choosing Polypropylene for Sterile Cleaning

Why has polypropylene become the material of choice for handles in critical cleaning applications? The answer lies in its unique combination of chemical, physical, and economic properties that outperform many alternative materials.

Superior Chemical Resistance

Polypropylene is inherently resistant to a wide range of acids, bases, and solvents. This is a critical advantage when swabs are used with aggressive cleaning agents like isopropyl alcohol, acetone, or specialized detergents. Unlike metals that can corrode or other plastics that can swell or degrade, PP maintains its structural integrity, ensuring no secondary contamination from the swab handle itself. For instance, when comparing PP to a common alternative like polystyrene (PS) in contact with a strong solvent, the difference is clear. Polystyrene may craze or dissolve, while polypropylene remains completely unaffected, preserving the purity of the cleaning process.

Low Particulate and Fiber Shedding

The manufacturing process for high-quality PP swabs is designed to minimize the generation of particles and fibers. This is paramount in cleanrooms and sensitive assembly areas where a single micro-sized particle can cause a catastrophic failure in a microchip or a medical device. The smooth, moldable nature of polypropylene allows for the production of handles without seams or rough edges that could shed material during use.

Economic and Practical Benefits

From a procurement perspective, polypropylene is a cost-effective material, which makes bulk sterile pp cleaning swabs for manufacturing a financially viable option without compromising on quality. Its durability prevents breakage during storage or use, and its light weight helps keep shipping costs low, especially for large, wholesale orders. Furthermore, the material's compatibility with various sterilization methods, including gamma irradiation and ethylene oxide, ensures a sterility assurance level (SAL) of 10^-6, meaning there is less than a one-in-a-million chance of a single viable microorganism being present on the swab.

Critical Factors in Swab Selection

Selecting the right sterile swab is not a one-size-fits-all process. A swab that is perfect for cleaning a large surface area in a factory may be entirely unsuitable for a precision task in a laboratory. Making the correct choice requires a careful evaluation of several key factors.

Handle Material and Design

The handle is the backbone of the swab. While this article focuses on the benefits of polypropylene, it is important to understand its position relative to other materials. The following comparison highlights key distinctions:

When comparing polypropylene to wood or paper, the advantages for industrial use are significant. Wooden handles can splinter and are not compatible with many liquids, while paper handles can lose integrity when wet. In contrast, polypropylene is durable and chemically inert. Compared to more expensive materials like certain thermoplastics, PP offers a superior balance of performance and cost, making it ideal for high-volume usage.

| Handle Material | Chemical Resistance | Particulate Shedding | Cost-Effectiveness | Ideal Use Case |

|---|---|---|---|---|

| Polypropylene (PP) | High | Very Low | High | General industrial and lab use with various solvents |

| Wood | Low | High | Medium | Non-critical, dry or low-moisture applications |

| Paper | Very Low | Medium | High | Single-use, low-cost applications without liquids |

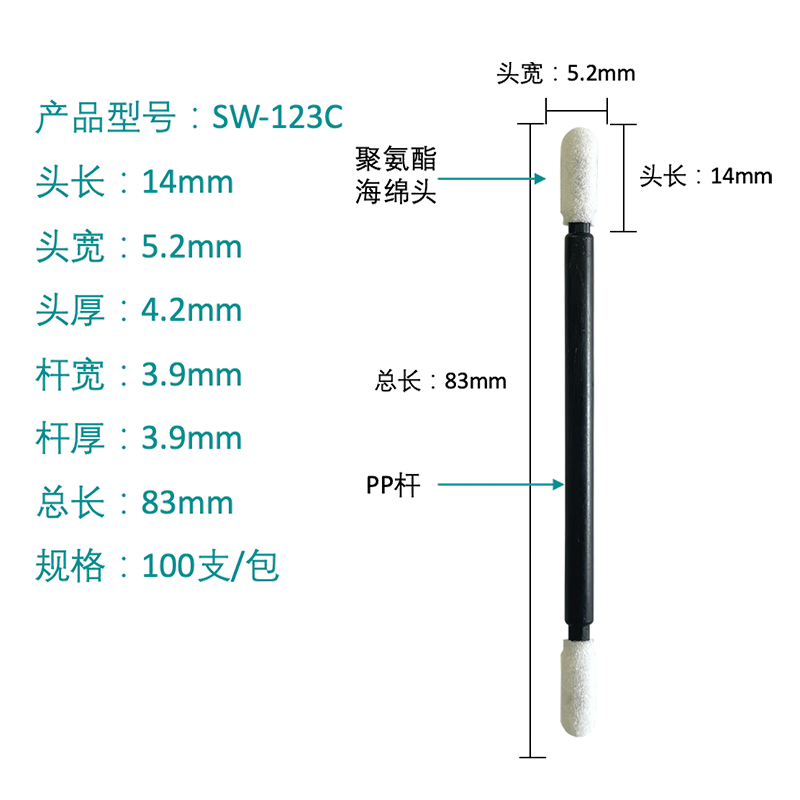

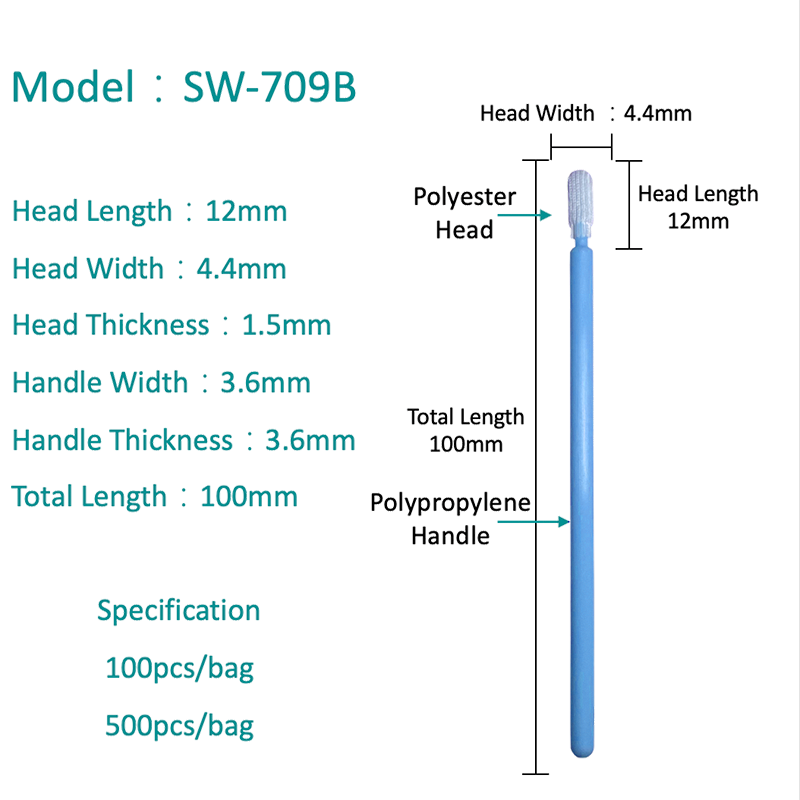

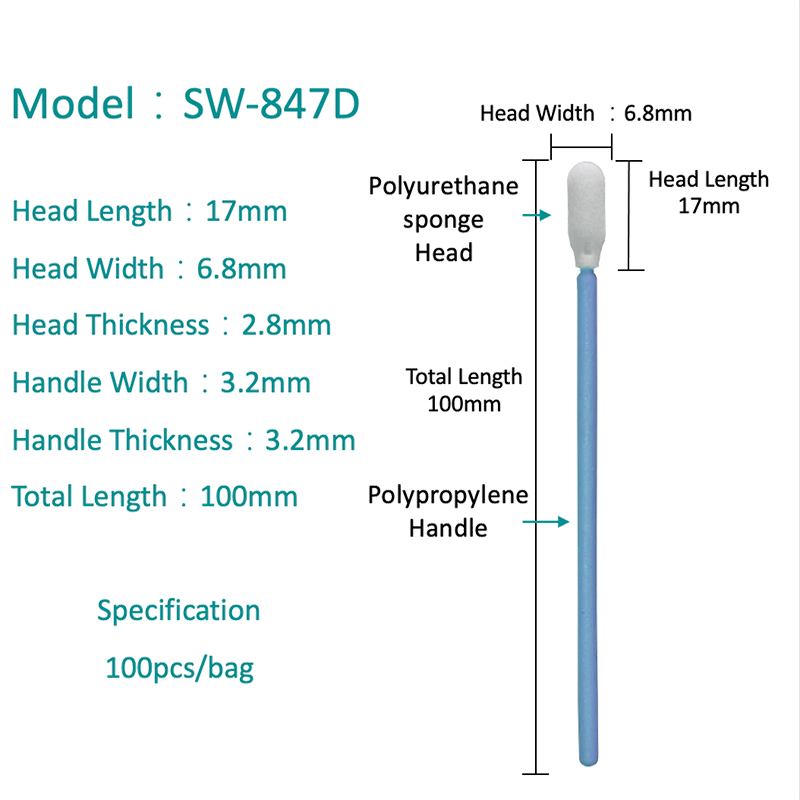

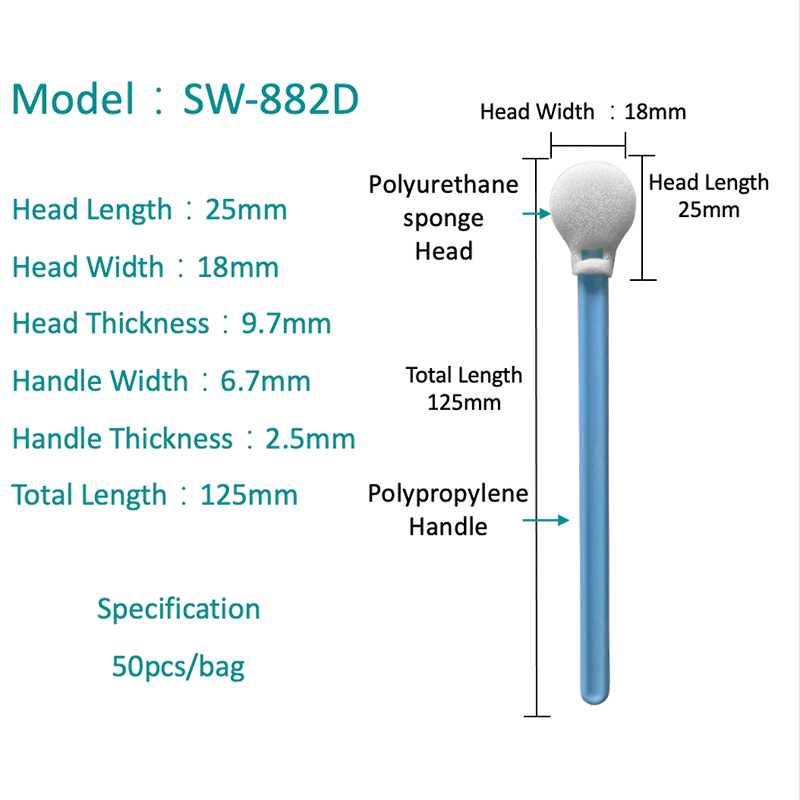

Tip Material and Configuration

The tip is the business end of the swab, and its material dictates its absorbency, abrasiveness, and compatibility.

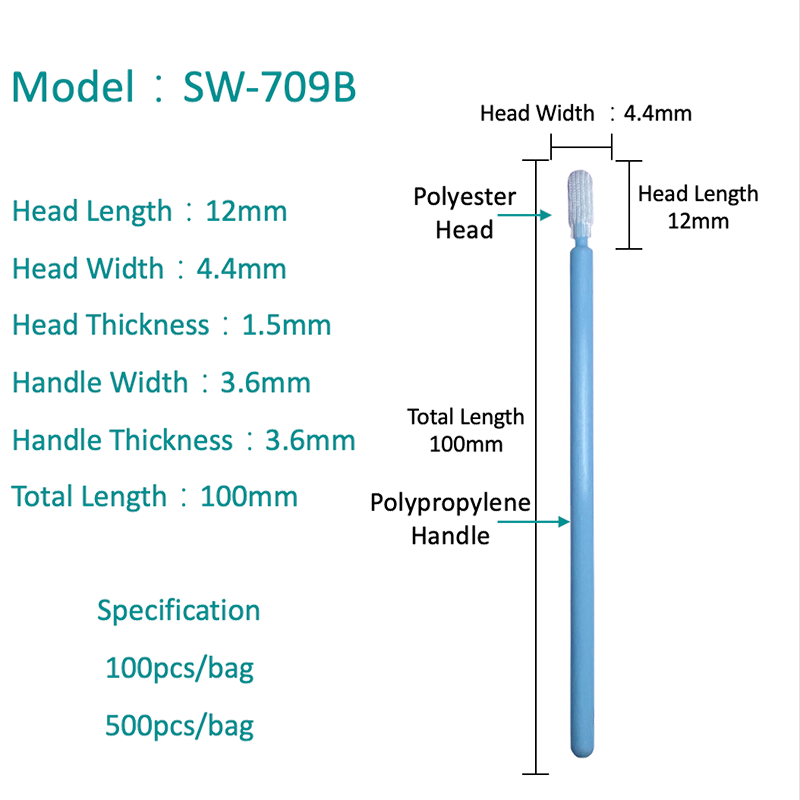

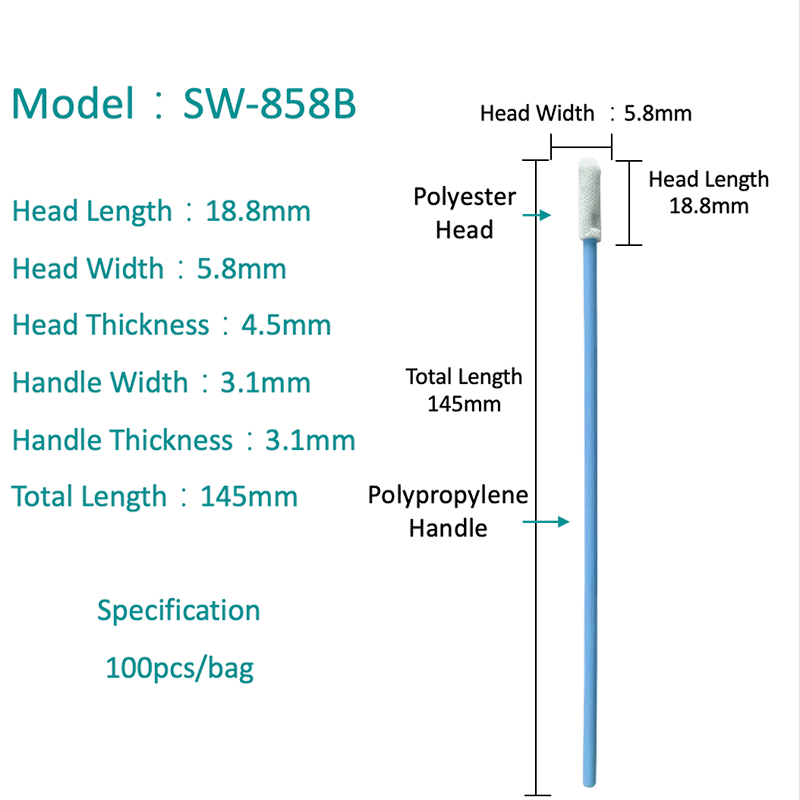

- Polyester (PES): Offers excellent absorbency for liquids and is low in particulate generation. It is a good general-purpose material for cleaning and wiping.

- Polyurethane (PU): Highly absorbent and open-cell structure, making it excellent for solvent cleaning and application.

- Cotton: While highly absorbent, traditional cotton can have loose fibers and may not be as pure as synthetic alternatives, making it less suitable for critical environments.

- Microfiber: Provides a very large surface area for trapping and holding fine particles, excellent for dusting and polishing sensitive surfaces.

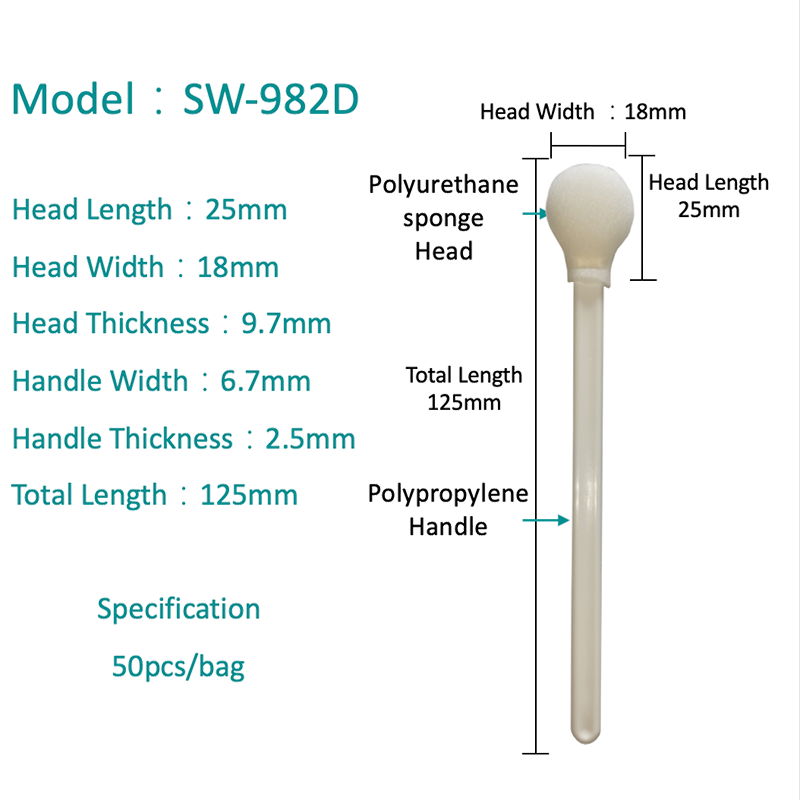

The shape of the tip—such as pointed, rounded, or flat—also determines its application. A pointed tip is designed for precision cleaning in tight spaces, while a flat tip offers a larger surface area for efficient swabbing of flat surfaces.

Sterility Assurance and Packaging

For a swab to be truly "sterile," the entire manufacturing and packaging process must be controlled. Look for swabs that are manufactured in a cleanroom environment and sterilized using a validated method. The packaging should be a validated, breathable Tyvek® or medical-grade paper pouch that maintains sterility until the point of use. This is non-negotiable for applications in aseptic processing, medical device manufacturing, and any laboratory work involving cell cultures or PCR. Ensuring your wholesale supplier can provide Certificates of Analysis (CoA) and sterilization validation reports is a key part of the due diligence process.

Finding the Right Wholesale Supplier

Sourcing wholesale industrial sterile pp cleaning swab requires more than just finding the lowest price. It involves partnering with a supplier who understands the technical requirements of your industry and can provide consistent, high-quality products. A reliable supplier for sterile pp swabs for cleanroom use will have a deep understanding of ISO classifications, GMP guidelines, and the critical nature of their products in your workflow. They should be able to provide detailed product specifications, material safety data sheets (MSDS), and full traceability for their products. When evaluating a supplier, consider their manufacturing capabilities, their quality control processes, and their ability to provide custom solutions if your operation requires a specific swab configuration not available off-the-shelf. A supplier that offers custom sterile pp swabs wholesale is demonstrating a commitment to serving the unique needs of their clients, which is a valuable trait in a long-term partner. Furthermore, for operations with diverse needs, a supplier that can provide a wholesale assortment of lab cleaning swabs can simplify the procurement process, allowing you to source different tip materials and handle lengths from a single, trusted vendor. This consolidates your supply chain and reduces administrative overhead. Finally, the economic benefit of purchasing bulk sterile pp cleaning swabs for manufacturing cannot be overstated. The per-unit cost savings are obvious, but the broader benefit is the assurance of a stable supply, preventing costly production halts due to a lack of this essential consumable. A dependable wholesale partner becomes an integral part of your operation's risk management strategy.

Maximizing Value in Your Procurement Strategy

Transitioning to a wholesale model for essential consumables like sterile PP swabs is a strategic decision that impacts both your budget and operational reliability. To truly maximize value, procurement should be viewed through a lens of Total Cost of Ownership (TCO), which goes beyond the sticker price. This includes factors such as the consistency of product quality (reducing the risk of costly errors or rework), the reliability of delivery (preventing production downtime), and the efficiency of the ordering and fulfillment process. Establishing a vendor qualification program that rigorously assesses a supplier's quality management systems, financial stability, and customer service capabilities is crucial. By building a strong relationship with a qualified wholesale supplier, you secure not just a product, but a partnership that contributes to the smooth, efficient, and uncontaminated operation of your labs and factories. This proactive approach to procurement ensures that the simple cleaning swab remains a reliable asset in your quality control arsenal, rather than a potential point of failure.

English

English  中文简体

中文简体