HOME / NEWS / Industry News / Precision Tips, Superior Absorbency: The Science Behind the Microfiber Swab

In a world where we are surrounded by expensive, delicate electronics and precision instruments, the tools we use to maintain them matter more than ever. Enter the humble microfiber swab, a seemingly simple tool that is, in fact, an engineering marvel. Far more sophisticated than a cotton swab, its design is a direct application of material science aimed at achieving one goal: flawless cleaning without damage. This article delves deep into the technology behind these indispensable tools, exploring how their unique structure grants them superior absorbency and allows for pinpoint precision, making them the undisputed champion for cleaning everything from camera sensors to intricate circuitry.

The Engineering Marvel: What is a Microfiber Swab?

At first glance, a microfiber swab might be mistaken for its cotton counterpart. However, a closer look reveals a world of difference. Traditional cotton swabs are made from natural fibers which are relatively large and can leave behind lint or even micro-scratches on sensitive surfaces. Microfiber, as the name suggests, is composed of synthetic fibers, typically a blend of polyester and polyamide, that are split into strands many times finer than a human hair. This splitting process creates an immense surface area within a small space. The core of a quality microfiber swab is not just about the material; it's also about the construction. The tip is meticulously designed to be ultra-fine and often features a pointed or chiseled shape to access tight spaces. The handle is usually made of a rigid yet smooth plastic or paper to provide control without the risk of breaking and causing further contamination. This combination of material and design is what transforms it from a simple stick into a precision cleaning instrument.

- Material Composition: A blend of polyester (for structure and scrubbing) and polyamide (for absorbency).

- Fiber Structure: Split fibers create a massive surface area for trapping particles and moisture.

- Physical Design: Features a fine, often non-abrasive tip attached to a sturdy, application-specific handle.

- Key Differentiator: Unlike cotton, it captures and holds debris instead of pushing it around or leaving fibers behind.

How Microfiber's Structure Creates Superior Absorbency

The term superior absorbency is not just marketing hype; it's a direct result of microfiber's physical properties. The magic lies in the capillary action facilitated by the incredibly thin and densely packed fibers. Think of a paper towel soaking up a spill; microfiber works on the same principle but on a microscopic and far more effective level. The vast network of tiny gaps between the ultra-fine fibers acts like a labyrinth, drawing in and trapping liquids, oils, and microscopic particles through capillary force. Furthermore, the polyamide component of the blend is hygroscopic, meaning it naturally attracts and holds water molecules. This dual-action—capillary action and hygroscopic attraction—ensures that moisture and contaminants are lifted from the surface and locked deep within the swab's structure, drastically reducing the chance of re-depositing them during the cleaning process. This makes it exceptionally effective for cleaning camera lenses and other optical surfaces where streaks are unacceptable.

- Capillary Action: The microscopic spaces between fibers wick away liquids with high efficiency.

- Hygroscopic Nature: The material actively attracts and binds water molecules.

- High Surface Area: Provides immense space to trap and hold dust, grease, and bacteria.

- Result: Achieves a dry, streak-free finish that cotton cannot match.

Key Applications for Precision Microfiber Swabs

The unique properties of microfiber swabs make them indispensable across a wide range of hobbies and professions. Their ability to clean effectively without causing damage is paramount in fields where a single speck of dust or a minor scratch can have significant consequences. For photographers and videographers, they are the first line of defense in maintaining the clarity of their expensive equipment. In electronics manufacturing and repair, they provide the necessary precision to clean delicate components without leaving conductive lint behind. Even in sophisticated hobbies like model building or watchmaking, these swabs are used for applying solvents or cleaning intricate details. The common thread in all these applications is the need for a tool that offers control, absorbency, and a guarantee against secondary contamination.

- Electronics Cleaning: Safely removing flux residue, dust, and oils from circuit boards and connectors.

- Photography & Optics: Cleaning camera lenses, sensors, filters, and eyepieces without scratching or streaking.

- Automotive & Aviation: Detailing tight spaces on dashboards, instruments, and applying compounds.

- Jewelry & Watchmaking: Precisely applying cleaners and polishing compounds to delicate mechanisms.

- Laboratory Use: Handling and cleaning sensitive optical equipment and instruments in a controlled environment.

Microfiber Swab vs. Cotton Swab: A Detailed Comparison

While they may look similar, the functional differences between a microfiber swab and a common cotton swab are vast and significant. Choosing the wrong tool can lead to costly damage, making this comparison critical for anyone working with sensitive items. Cotton swabs are made from natural fibers that are soft but large and can easily break off, leaving behind lint on the surface you are trying to clean. This lint can clog delicate mechanisms in electronics or create blurry spots on optical surfaces. Furthermore, cotton tends to push dust around rather than capturing it. In contrast, a microfiber swab is designed specifically to eliminate these problems. Its synthetic fibers are lint-free and far more durable. The split-fiber structure actively grabs and traps particles and moisture, lifting them away from the surface for a truly clean result.

| Feature | Microfiber Swab | Cotton Swab |

| Fiber Material | Synthetic (Polyester/Polyamide) | Natural Cotton |

| Lint Generation | Lint-free | High lint generation |

| Absorbency | Extremely High (Superior Absorbency) | Moderate |

| Scratch Risk | Very Low (non-abrasive) | Moderate to High (can scratch sensitive surfaces) |

| Primary Use Case | Precision cleaning of sensitive surfaces | General purpose, cosmetic, or medical application |

| Debris Removal | Captures and traps particles | Often pushes particles around |

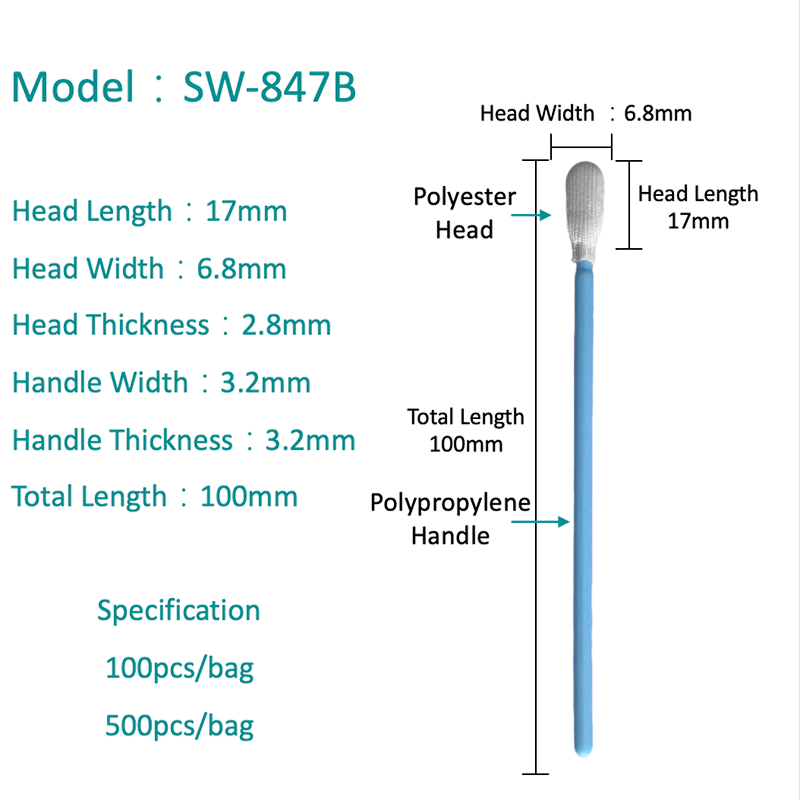

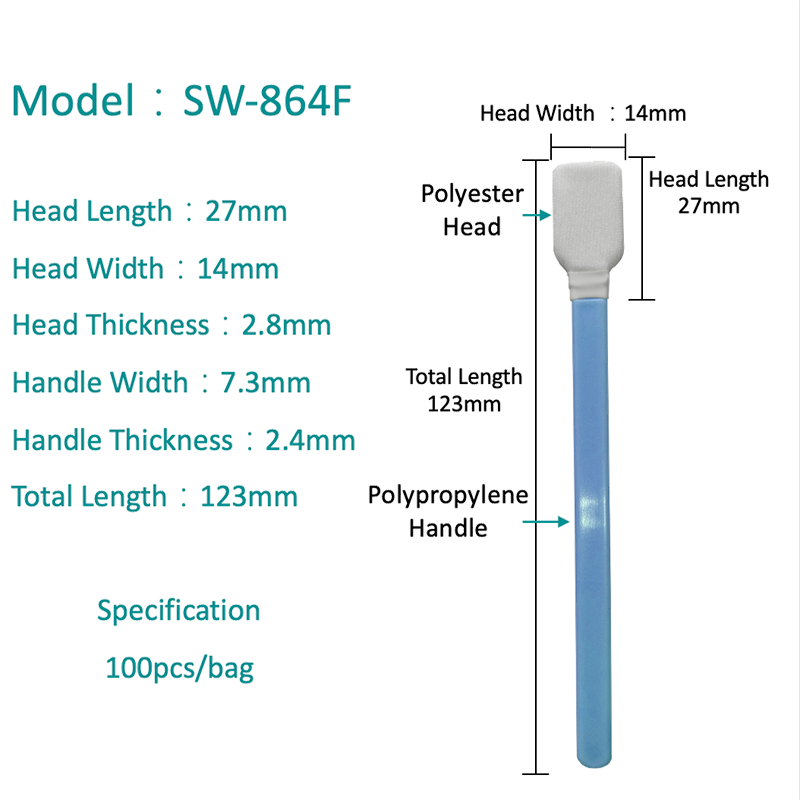

How to Choose the Right Microfiber Swab for Your Needs

Not all microfiber swabs are created equal. Selecting the right one is crucial for achieving a perfect clean without inadvertently causing damage. The key factors to consider are the tip shape, the handle material, and the density of the microfiber. A pointed tip is ideal for reaching into tight corners, such as between keyboard keys or in small electronic connectors, making it a great choice for those looking for the best swab for electronics. A flat or chisel tip offers a broader surface area, perfect for wiping across camera sensors or larger lenses. The handle is also important; a plastic handle provides rigidity for applying slight pressure, while a paper handle is often used in static-sensitive environments like cleanrooms. Understanding these variations will ensure you use the optimal tool for the job.

- Tip Shape:

- Pointed Tip: For precision work in tight spaces and corners.

- Flat/Chisel Tip: For swiping across flat surfaces like sensors.

- Round Tip: For general-purpose cleaning and applying solutions.

- Handle Type:

- Plastic: Rigid and good for control, but not for ESD-sensitive areas.

- Paper: Often used in cleanrooms and electronics to prevent static discharge.

- Wood: Less common, but provides a sturdy, biodegradable option.

- Fiber Density: A tighter weave is less absorbent but better for light dusting, while a looser weave is more absorbent for liquids.

Proper Technique for Cleaning a Camera Sensor Safely

Cleaning a camera sensor is a task that strikes fear into the hearts of many photographers, but with the right tools and technique, it can be done safely and effectively. The goal is to remove dust and oil spots without touching the sensor's fragile anti-aliasing filter. The first step is always to use a rocket blower to dislodge any loose particles. For stubborn spots, a microfiber swab designed specifically for sensor cleaning is required. These swabs are typically wider to match the sensor's size. A single drop of specialized sensor cleaning fluid is applied to the swab's tip. Holding the camera with the mount facing down, you gently swipe the swab across the sensor in one smooth motion, flip it over, and swipe again on the return journey. This technique utilizes the superior absorbency of the microfiber to lift and trap the contaminant without needing to press down, minimizing any risk of damage.

- Step 1: Diagnosis: Use your camera's sensor cleaning mode to lock the mirror up and take a test shot of a white wall at a narrow aperture (e.g., f/16) to reveal dust spots.

- Step 2: Dry Cleaning: Always start with a rocket blower to remove loose dust. Do not use canned air.

- Step 3: Wet Cleaning: Use a single drop of solvent on a sensor-specific microfiber swab. Never apply solvent directly to the sensor.

- Step 4: The Swipe: One confident, smooth swipe across the sensor per side of the swab. Do not go back over the same area with a used swab.

- Step 5: Verification: Take another test shot to confirm the spot is gone. Repeat only if necessary.

FAQ

Can I reuse a microfiber swab?

It is highly discouraged to reuse a microfiber swab, especially for high-stakes tasks like cleaning camera lenses or sensors. After a single use, the swab's fibers are filled with the contaminants it picked up. Reusing it risks re-depositing those same particles, grease, or oils onto your sensitive equipment, effectively undoing your cleaning work and potentially causing scratches. For general-purpose cleaning of less critical items, some sturdy swabs can be carefully cleaned with isopropyl alcohol and water, but they must be thoroughly air-dried to avoid contamination. For guaranteed results, always use a fresh, sterile swab for each precision cleaning session.

What is the best way to clean delicate electronic components?

The best swab for electronics is a lint-free microfiber swab, often with a plastic or static-dissipative handle. The optimal technique involves using a high-purity isopropyl alcohol (90% or higher) as a solvent. Lightly moisten the swab's tip with the alcohol—it should be damp, not dripping. Gently wipe the component, such as a circuit board connector or a smartphone port, using the swab to dissolve and absorb fluxes, oils, and dirt. The superior absorbency of the microfiber will pull the contamination away. Use a rolling motion with the swab to present a clean surface as you work. Allow the area to completely air dry before applying power to avoid short circuits.

Are microfiber swabs safe for all surfaces?

While microfiber swabs are exceptionally safe for most hard, smooth surfaces, caution is advised on certain materials. They are perfectly safe and recommended for glass, hardened plastics, metals, and coated optics. However, they may not be suitable for some very soft plastics or acrylics, as any material, if rubbed with enough pressure, could potentially cause micro-abrasions over time. It is always best to test the swab on a small, inconspicuous area first. Furthermore, ensure the swab is clean and the correct solvent is used for the specific contaminant and surface type. Their design minimizes risk, but the user must always exercise judgment based on the surface's sensitivity.

How do I avoid streaks when cleaning glass?

Avoiding streaks when cleaning camera lenses or any glass surface requires the right tool and technique. The key is to use a high-quality microfiber swab that is perfectly clean and designed for optics. First, use a blower to remove any abrasive dust particles. If needed, apply a minimal amount of lens cleaning solution specifically designed for coated optics to the swab—never directly to the lens. Using a circular motion, start from the center and work outwards. The superior absorbency of the microfiber will lift and trap the solution along with the dirt, rather than smearing it across the surface. Use a dry part of the swab or a fresh, dry microfiber cloth to gently buff any remaining moisture for a crystal-clear, streak-free finish.

English

English  中文简体

中文简体