HOME / NEWS / Industry News / Why Polyester Swab Becomes the New Standard in the Cleaning Industry?

1. Polyester Swab: A New Standard in Advanced Cleaning Technology

1.1 Superior Adsorption Power Beyond Traditional Tools

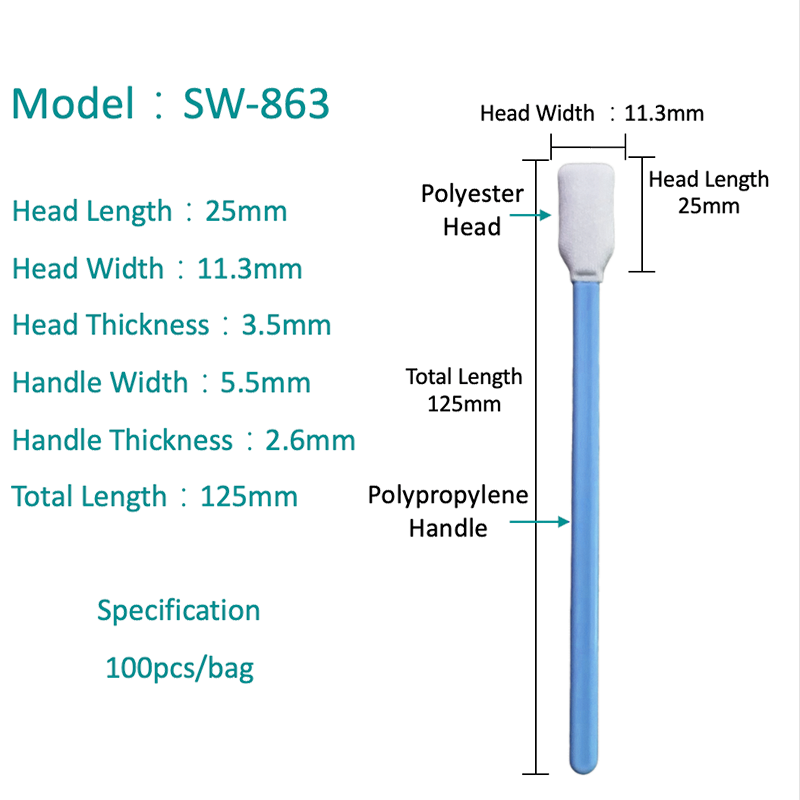

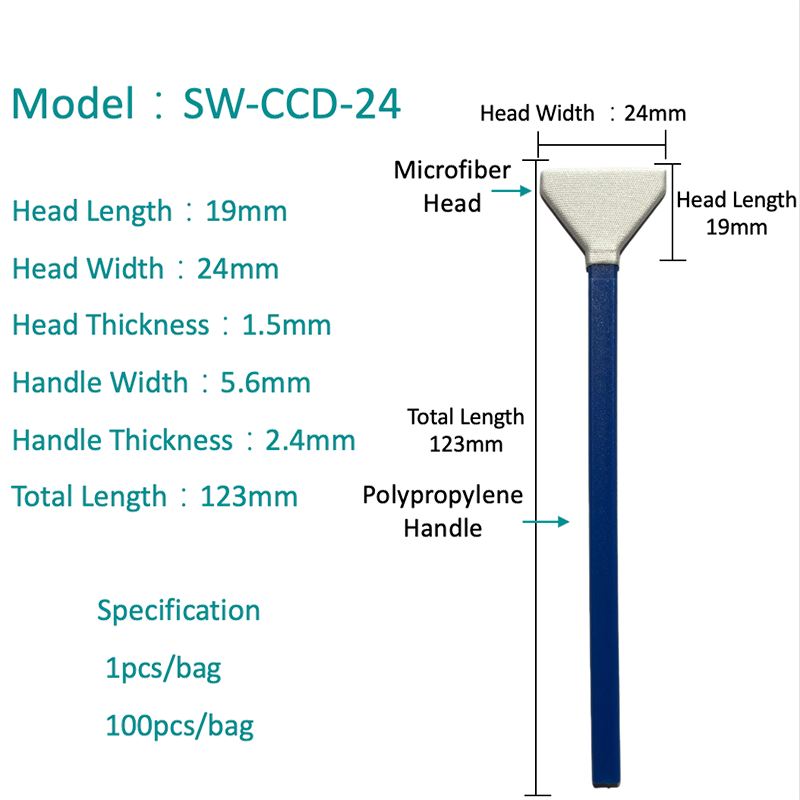

Polyester Swab is made from high-performance polyester fibers, engineered with a fine fiber network structure that offers rapid and efficient adsorption of dust, dirt, liquids, and bacteria. This precision design surpasses the adsorption capacity of traditional cotton swabs, especially in challenging humid environments where cotton swabs often fall short. The unique fiber composition ensures that pollutants are securely captured and locked during cleaning, guaranteeing a cleaner and safer surface.

1.2 Consistent Performance in Various Conditions

Unlike conventional cotton swabs whose absorption decreases in moisture, Polyester Swabs maintain excellent adsorption capabilities whether dry or wet. Their fiber structure is resilient and adaptable, enabling superior cleaning results across different environments and ensuring that cleaning tasks are performed efficiently regardless of external conditions.

1.3 An Indispensable Tool Across Industries

Due to their exceptional adsorption and durability, Polyester Swabs have become essential in multiple sectors requiring stringent cleaning standards, such as electronics, healthcare, and manufacturing. Their ability to rapidly absorb contaminants without degradation or fiber shedding makes them a preferred choice for maintaining high hygiene and precision in critical applications.

2. Comprehensive Cleaning Efficiency: Detail-Oriented and Precise

2.1 Effective Removal of Fine Stains and Pollutants

Polyester Swabs excel in capturing even the most stubborn contaminants including tiny particles, liquids, and bacteria that traditional tools often fail to remove. Their superior adsorption ensures that common and complex pollutants are addressed, preventing residual contamination and enhancing the overall cleanliness of surfaces.

2.2 Precision Cleaning in Hard-to-Reach Areas

Thanks to their flexible and finely structured fibers, Polyester Swabs can access narrow gaps, crevices, and corners that are difficult for traditional tools to reach. This capability ensures every detail is thoroughly cleaned without damaging delicate surfaces, elevating cleaning quality and operational efficiency in high-demand environments.

2.3 Enhancing Work Quality through Thoroughness

In industries where cleanliness directly impacts product quality and safety, the thorough cleaning capability of Polyester Swabs ensures that every cleaning cycle meets rigorous standards. Their ability to leave surfaces pristine and uncontaminated contributes to improved workflow and product integrity.

3. Adaptability and Precision: Meeting the Demands of Modern Cleaning

3.1 Exceptional Performance in Wet and Humid Environments

Polyester Swabs retain their adsorption strength and cleaning effectiveness even under wet conditions, overcoming limitations faced by traditional cotton swabs. This adaptability ensures uninterrupted, efficient cleaning processes in environments such as laboratories, medical facilities, and manufacturing plants where moisture is prevalent.

3.2 Durable Fiber Structure for Long-Term Use

Constructed from durable polyester fibers, these swabs resist degradation and maintain their structural integrity through repeated use. This longevity reduces replacement frequency and supports sustained high-quality cleaning performance over time, delivering excellent value and reliability.

3.3 Precision Cleaning with Minimal Residue

Polyester Swabs minimize fiber shedding and avoid leaving behind residues that could compromise cleaning results. Their dense and tough fiber structure firmly absorbs contaminants, ensuring residue-free surfaces essential for precision cleaning in sectors requiring the highest standards, such as electronics assembly and healthcare equipment maintenance.

English

English  中文简体

中文简体