HOME / NEWS / Industry News / Do you know how V-Shape Lens Microfiber Swab achieves traceless cleaning?

1. A new revolution in cleaning - the urgent need for traceless cleaning

With the continuous development of science and technology, the importance of optical equipment and precision instruments in many fields such as industry, medicine, electronics and photography has become increasingly prominent. Their performance and service life are often directly affected by the quality of surface cleaning. Key components such as lenses, optical sensors, and display screens can easily cause blurred imaging, data errors, and even equipment damage if the surface is contaminated with dust, oil or particles.

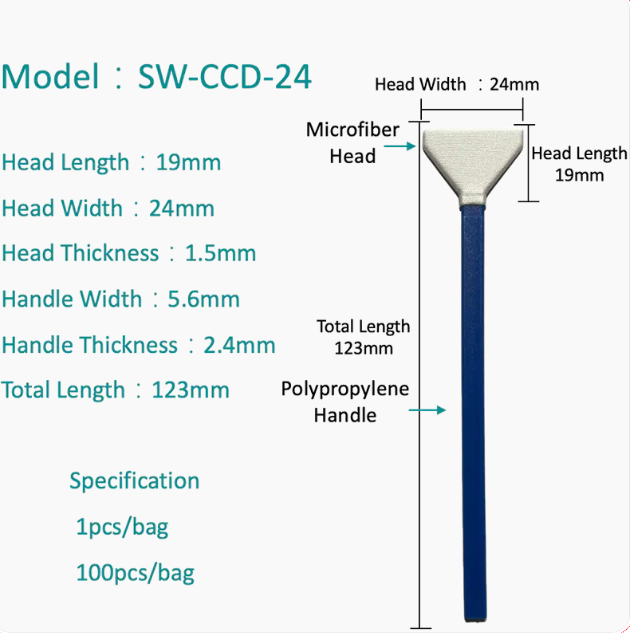

However, traditional cleaning methods such as ordinary cotton cloth, paper towels, and even wiping with chemical solvents are difficult to completely solve the scratches, residues or static electricity problems generated during the cleaning process, which brings great challenges to equipment maintenance. Against this background, the revolutionary V-Shape Lens Microfiber Swab came into being and became a key tool for efficient and traceless cleaning. This new wiping stick not only incorporates an innovative V-shaped structure design, but also uses high-performance microfiber materials, which can minimize surface damage during cleaning, improve cleaning efficiency, and meet the stringent requirements of high-precision equipment.

2. Unique advantages of V-Shape design

The V-Shape design is one of the most significant innovative features of the microfiber wiping stick. Traditional wiping tools are mostly flat or simple cylindrical, with limited contact area, difficult to adapt to complex curved surfaces and gaps, and prone to uneven pressure, resulting in incomplete cleaning or even scratches.

2.1. Design concept of V-shaped structure

The V-shaped structure can naturally fit the curvature and contour of the lens or optical surface by designing the wiping head into an open "V" shape. This structure allows the two "arms" of the wiping stick to flexibly adjust the angle, disperse the pressure, and avoid damage caused by high pressure at a single point. At the same time, the V-shaped opening can better capture and take away stains and particles to prevent secondary contamination.

2.2. Improve contact area and cleaning efficiency

Because the V-shaped design expands the contact range with the surface to be cleaned, it can cover more areas, reduce the number of cleaning times, and greatly improve efficiency compared to traditional flat wiping methods. In addition, the V-shaped wiping surface can reach hard-to-reach locations such as edges and grooves to ensure comprehensive cleaning.

2.3. Principle of effectively avoiding residue and scratches

Residual fibers or scratches caused by wiping during cleaning are important factors affecting equipment performance. The V-shaped structure combined with the softness of the microfiber material can gently touch the surface, reduce the friction coefficient, and effectively avoid scratches. At the same time, the stains are locked in the V-shaped groove during wiping, and are not easy to fall back on the surface, ensuring that there is no residue after cleaning.

3. Core technology of Microfiber materials

Microfiber technology is another core element to achieve traceless cleaning. Microfiber is a high-tech material composed of extremely fine polyester and polyamide blended fibers, and the fiber diameter is usually only one-tenth of a human hair or even finer.

3.1. Introduction to the characteristics of microfiber

Microfiber has extremely high fineness and large surface area, and can produce extremely strong adsorption and cleaning power. The gaps between the fibers can capture and lock dust, grease and tiny particles to prevent them from spreading again. In addition, microfiber is highly soft and will not scratch or damage precision surfaces, which is particularly suitable for cleaning highly sensitive materials such as optical lenses.

3.2. Advantages of materials with strong adsorption, softness and no damage to the surface

Microfiber materials can effectively absorb dust and oil through electrostatic and capillary action, and can absorb a certain amount of water or detergent to improve the dissolution and removal of stains. Compared with traditional materials, microfiber can remove stains more thoroughly and reduce chemical residues.

3.3. Relationship between fiber structure and traceless cleaning

The ultra-fine fiber structure of microfiber can form an effect similar to "bristles", but it is softer and more delicate than ordinary bristles, and can clean deeply in fine textures and grooves, avoiding dead corners that ordinary cloth cannot reach. In addition, its unique weaving method reduces the problem of shedding fibers and avoids leaving fluff after cleaning.

4. Analysis of the working mechanism of traceless cleaning

4.1. Combination of physical cleaning and chemical cleaning

Traceless cleaning does not only rely on physical wiping, but also pays attention to the use of appropriate chemical detergents. The design of the V-shaped microfiber wiping stick enables it to give full play to the adsorption characteristics of microfibers, and with a small amount of environmentally friendly detergent, it can easily dissolve oil and stubborn stains, achieving deep cleaning without damaging the surface.

4.2. Dual realization of particle capture and polishing function

During the wiping process, microfibers capture tiny particles to prevent scratches caused by particle friction. At the same time, the soft texture of microfibers has a slight polishing effect on the optical surface, removing fine stains and water marks, making the lens cleaner and more transparent.

4.3. Anti-static design and its role in cleaning

Static electricity is one of the main causes of dust adsorption and difficulty in cleaning. The wiping stick is usually integrated with an anti-static design, which can reduce static electricity accumulation, reduce dust adsorption, and ensure long-lasting cleanliness after cleaning. At the same time, the anti-static function reduces secondary cleaning pollution caused by static electricity and improves the overall cleaning quality.

5. Usage and maintenance suggestions

5.1. Steps for using V-Shape Lens Microfiber Swab correctly

First check the cleaning surface to ensure that there are no large particles of dust to avoid scratches.

If a cleaning agent is required, choose a suitable environmentally friendly formula and spray or drip a small amount evenly.

Gently fit the V-shaped wiping head to the lens surface and wipe in one direction to avoid rubbing back and forth.

Wipe evenly and do not apply excessive pressure.

After wiping, wipe lightly with a clean microfiber cloth to ensure that there is no residue.

5.2. Common cleaning misunderstandings and avoidance strategies

Avoid using ordinary cotton cloth or paper towels instead of microfiber wiping to prevent scratches and fiber residue.

Avoid over-wetting the wiping stick to prevent liquid from penetrating into the device.

Do not use highly corrosive or volatile solvents on the lens.

Avoid excessive friction that causes surface wear.

5.3. How to extend the service life of cleaning tools

Wash the microfiber wiping head promptly after use to remove attached stains.

You can wash it gently by hand with warm water, avoiding high temperatures or strong alkaline detergents.

Store it in a dry and clean environment after drying it completely.

Replace the wiping head regularly to ensure the best cleaning effect.

6. Contribution to environmental protection and sustainable development

6.1. Reusability and environmentally friendly characteristics of materials

Microfiber wiping sticks have good durability and reusability, reducing the amount of disposable wiping tools that are discarded, reducing resource consumption, and helping environmental protection.

6.2. Green Concept in Production Process

In modern production processes, environmentally friendly materials and energy-saving technologies are used to minimize the impact on the environment while ensuring that the products are safe and harmless.

6.3. Practical Significance of Reducing Waste and Pollution

The efficient cleaning performance of microfiber swabs reduces the dependence on chemical detergents, fundamentally reduces chemical pollution of water and soil, and promotes the development of green cleaning technology.

7. Conclusion

With the widespread application of high-precision optical instruments and equipment, the requirements for cleaning technology are also increasing. V-Shape Lens Microfiber Swab achieves efficient, traceless and environmentally friendly cleaning effects with its innovative V-shaped design and advanced microfiber materials, becoming an indispensable secret weapon in industrial manufacturing, electronic products, medical equipment and other fields.

In the future, with the continuous advancement of technology and the diversification of user needs, this type of wiping tool will show greater potential in more market segments. By continuously optimizing design and materials, we will promote traceless cleaning to the direction of intelligence and automation, and look forward to bringing safer, more environmentally friendly and efficient cleaning solutions to the industry.

English

English  中文简体

中文简体