HOME / NEWS / Industry News / Why is cleanroom swab so important in cleanroom cleaning?

1.Cleanroom Swabs: The Unsung Heroes of Contamination Control

1.1 Combating Invisible Threats in Controlled Environments

Cleanrooms are designed to maintain ultra-low levels of airborne particles, but even microscopic contaminants such as dust, skin cells, volatile organic compounds (VOCs), and microbial matter can compromise operations. Whether in semiconductor manufacturing, biotechnology, or pharmaceutical industries, maintaining an uncontaminated environment is essential to product quality and regulatory compliance.

1.2 Hidden Pollutants Require Targeted Cleaning Strategies

Standard surface wiping is no longer sufficient. Contaminants often hide in minute crevices, on equipment edges, or within air duct intakes—areas inaccessible to general cleaning tools. Cleanroom swabs are engineered to reach these difficult locations, targeting particles that are invisible to the naked eye and often undetectable until they cause damage.

1.3 Cleanroom Swabs as Precision Cleaning Instruments

Designed with stringent particle-shedding control and non-linting materials, cleanroom swabs offer a level of precision unmatched by conventional tools. Their materials—often polyester or polyurethane foam—are chosen not only for absorbency but also for their ability to remove and retain particles without reintroducing them into the environment. This makes them critical in settings where contamination thresholds are measured in parts per billion.

2.Engineered for Performance: How Cleanroom Swabs Maximize Cleaning Efficiency

2.1 Advanced Absorption Technology for Contaminant Retention

The swab tip material is engineered to trap contaminants upon contact. Unlike rags or wipes that may smear or redistribute particles, cleanroom swabs employ capillary and adhesive mechanisms to securely hold dust, oils, and bio-residue. This minimizes the risk of secondary contamination, which is especially vital in aseptic and sterile areas.

2.2 Precision Wiping for Micro-Contamination Elimination

Thanks to their fine-textured, soft-yet-durable surface, cleanroom swabs excel in eliminating sub-micron particles, including oils, solder flux residues, and protein-based contaminants. Their wiping action gently lifts material from the surface without scratching or compromising sensitive components, such as photomasks or wafer surfaces.

2.3 Reduced Cleaning Time with Improved Results

Cleanroom swabs dramatically reduce the number of cleaning cycles required by increasing cleaning efficacy per pass. This not only saves time but also conserves solvents and cleaning agents. The result is a leaner, more sustainable cleaning protocol that meets rigorous ISO standards while supporting operational efficiency.

3.Versatile Design for Diverse Cleanroom Demands

3.1 Tailored Shapes for Specialized Applications

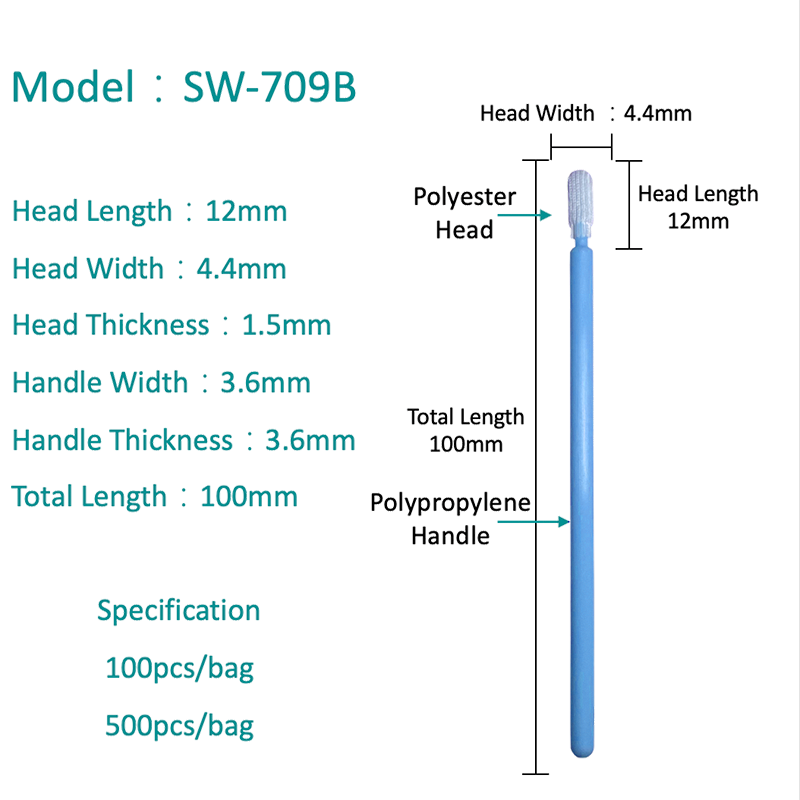

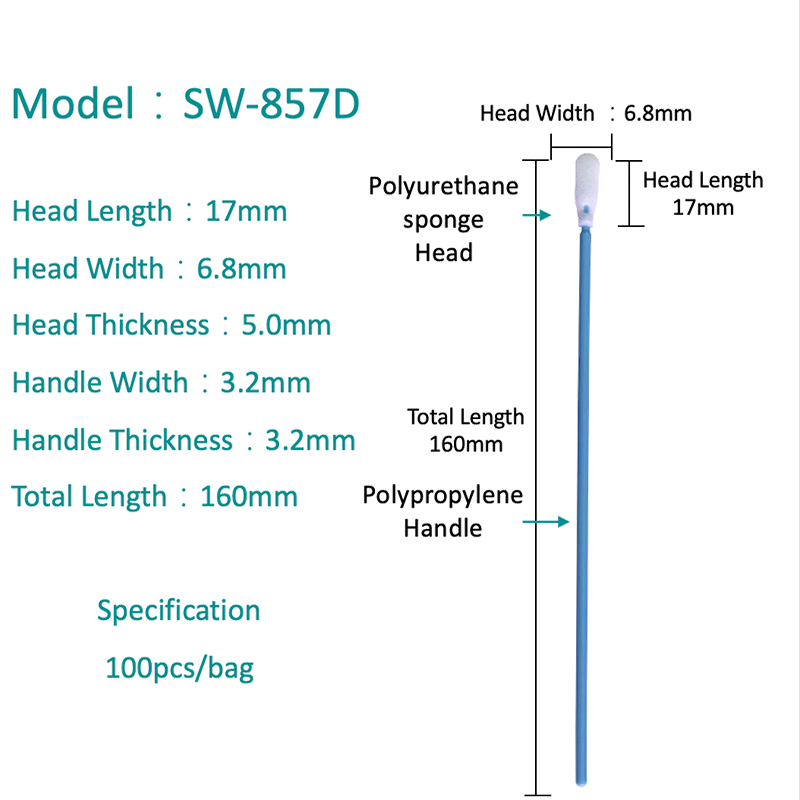

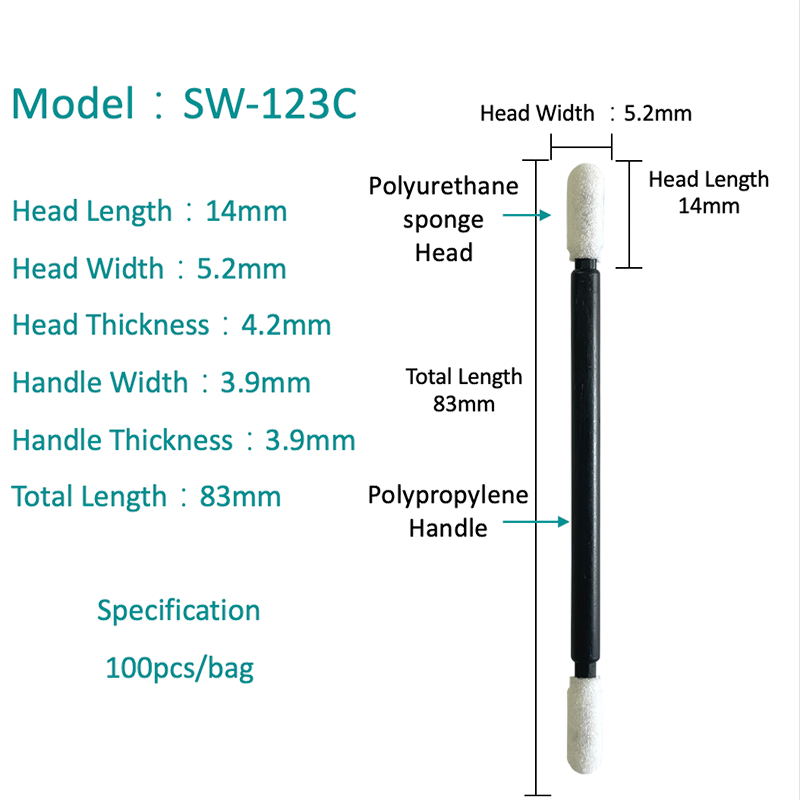

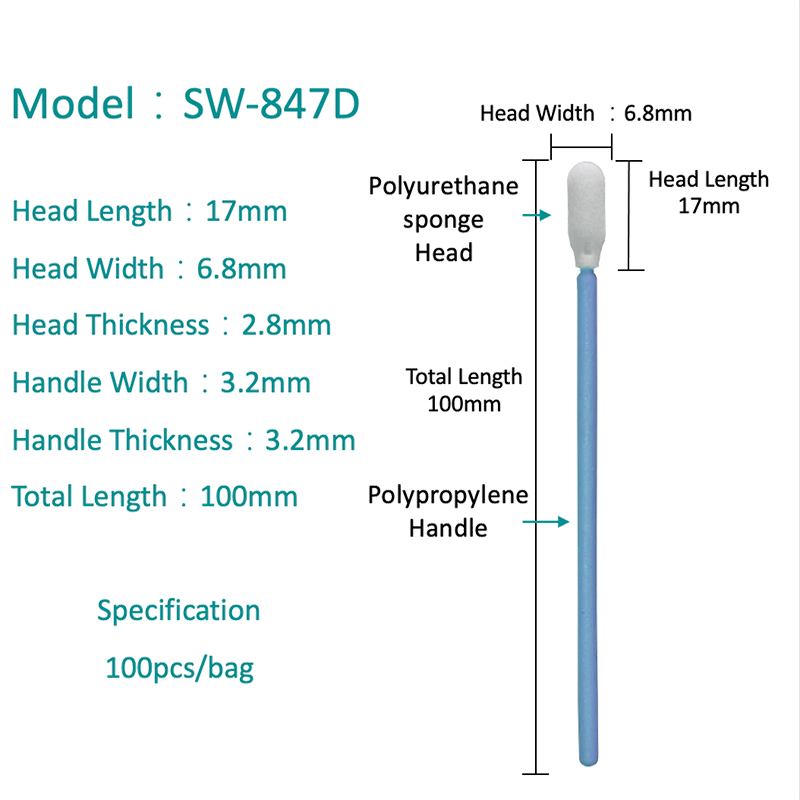

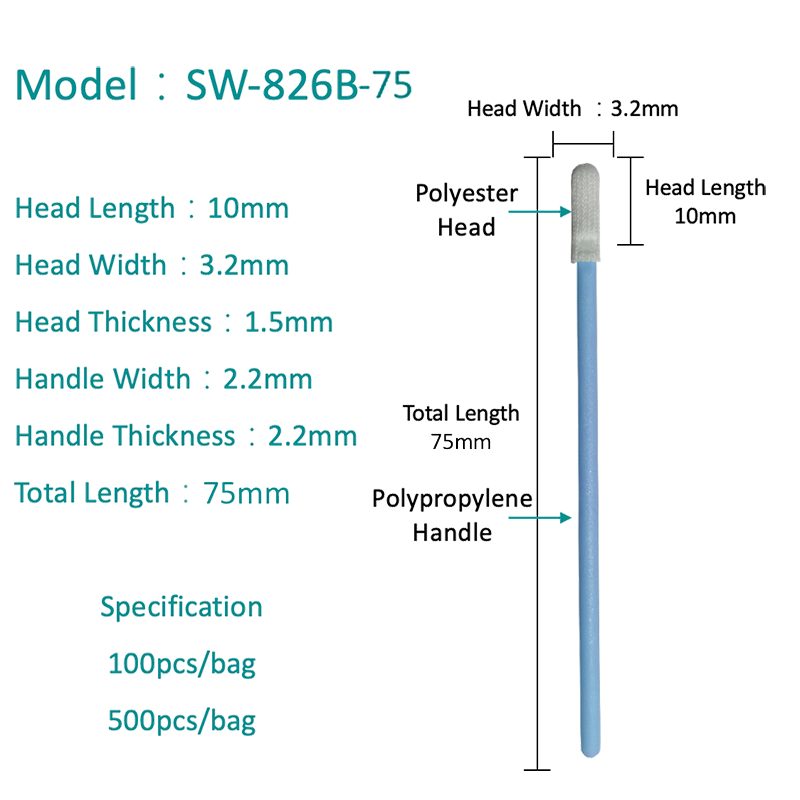

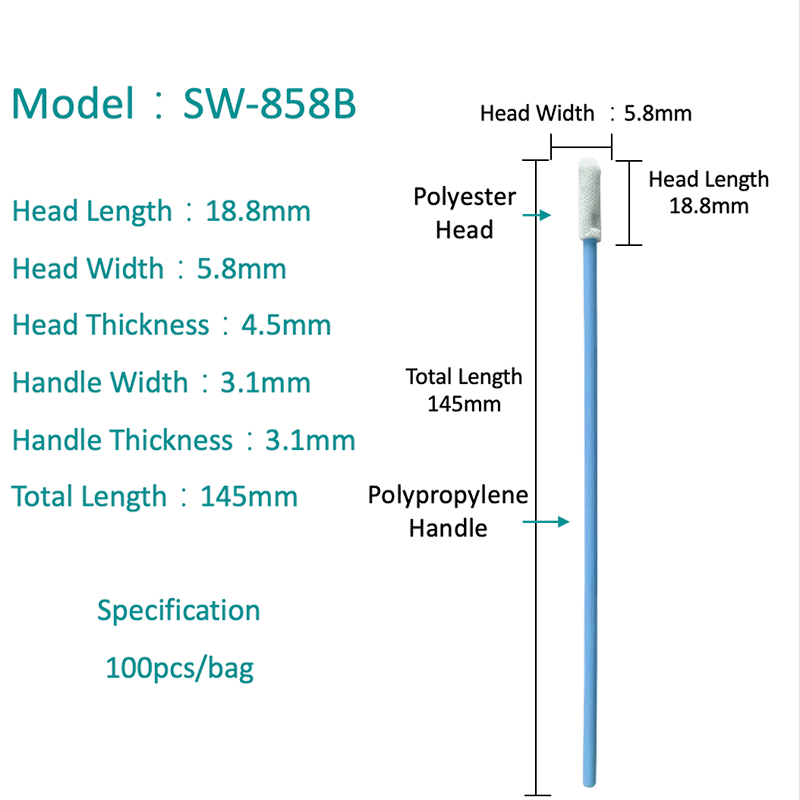

Cleanroom swabs come in a range of head sizes, shaft lengths, and shapes to accommodate various equipment geometries and contamination zones. From flat, paddle-style swabs for wide surfaces to pointed or narrow-tipped swabs for intricate cavities, their adaptability is central to effective contamination control.

3.2 Material Innovation for Varied Contaminant Profiles

Depending on the cleaning requirement—whether dry wiping, solvent-assisted cleaning, or static-sensitive area decontamination—different swab materials (e.g., knitted polyester, foam, microfiber) are used. These materials are tested for chemical compatibility, low ionic contamination, and resistance to particle shedding, enabling safe usage across a wide spectrum of industries.

3.3 Custom Solutions for Evolving Cleanroom Standards

As cleanroom applications expand into emerging sectors like nanotechnology, advanced optics, and gene therapy, cleaning tools must evolve accordingly. Cleanroom swab manufacturers now offer customized solutions tailored to client specifications, allowing for proactive contamination control strategies that align with both current and future operational requirements.

English

English  中文简体

中文简体