HOME / NEWS / Industry News / Why do foam tip cleaning swabs have unparalleled advantages in precision equipment cleaning?

1: Foam Tip Cleaning Swabs Redefine Deep Cleaning with Exceptional Adsorption

1.1: Unique Porous Foam Structure Enables Superior Stain Capture

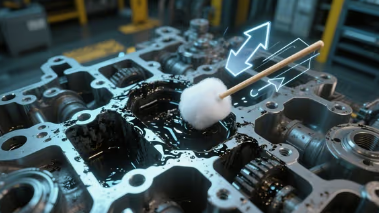

Foam Tip Cleaning Swabs utilize a specially engineered foam material with a high-density porous structure that behaves like countless miniature vacuum chambers. These micro-pores instantly trap dirt, dust, oil, and other fine particles upon contact, holding them securely within the foam matrix. Unlike conventional cloths or brushes that smear or redistribute contaminants, the foam tip achieves true containment, preventing recontamination of the cleaned surface.

1.2: Advanced Absorption Technology Targets Sub-Surface Pollutants

Traditional tools often fall short in cleaning embedded grime or fine dust, only addressing superficial stains. Foam Tip Cleaning Swabs, however, penetrate micro-textures and recesses, drawing out contaminants from even the most inaccessible areas. This allows for deeper, more effective cleaning that maintains surface purity and supports the proper functioning of sensitive devices.

1.3: Eliminates Cleaning Blind Spots for Comprehensive Results

Dead corners, seams, and small cavities are common obstacles in equipment cleaning. Foam Tip Cleaning Swabs’ soft, conformable structure adapts effortlessly to various geometries, ensuring no surface goes untreated. Whether in optical components, sensor housings, or microchips, these swabs deliver a complete, residue-free clean that standard tools cannot match.

2: Precision Meets Performance: Foam Tip Cleaning Swabs Excel in Particle Removal

2.1: Capturing Microscopic Debris with Surgical Precision

In fields like electronics and laboratory instrumentation, even microscopic dust particles can lead to signal interference or operational failure. Foam Tip Cleaning Swabs are engineered for precision-grade cleaning—removing particles invisible to the naked eye without damaging delicate surfaces. This fine-tuned capability ensures optimal performance for high-value, high-precision equipment.

2.2: Prevents Functional Degradation Caused by Particle Accumulation

Over time, accumulated contaminants can interfere with optical clarity, circuitry, or mechanical movement. Foam Tip Cleaning Swabs mitigate these risks through consistent, high-performance removal of grime and oil, preserving device functionality and reducing the need for frequent maintenance or costly repairs.

2.3: Elevates Cleanroom and Laboratory Protocols

Used in controlled environments, these swabs conform to stringent cleanliness standards. Their ability to trap and contain microscopic impurities ensures compliance with ISO cleanroom classifications and laboratory hygiene protocols, making them indispensable in industries where even minimal contamination is unacceptable.

3: Versatile, Efficient, and Safe – The Future of Professional-Grade Cleaning

3.1: Boosts Cleaning Efficiency While Reducing Downtime

The instant adsorption capability of the foam tip accelerates cleaning workflows. Unlike traditional methods that rely on repetitive strokes or heavy force, Foam Tip Cleaning Swabs minimize labor intensity while maximizing output. This translates to faster cleaning cycles, less downtime for equipment, and greater overall productivity in maintenance operations.

3.2: Prevents Secondary Contamination Through Secure Debris Retention

Many tools inadvertently spread dirt instead of removing it. Foam Tip Cleaning Swabs prevent this by locking contaminants inside the foam, avoiding the transfer of debris to adjacent areas. This safeguard is vital in sensitive cleaning applications such as medical devices, aerospace components, and semiconductor fabrication.

3.3: One Tool, Multiple Applications Across Industries

From intricate circuit boards to rugged mechanical surfaces, these swabs adapt seamlessly to flat, curved, and irregular geometries. Their universal compatibility and gentle, non-abrasive nature make them a reliable tool across a broad range of sectors—including electronics, automotive, medical, and laboratory industries—making them a staple in any professional cleaning toolkit.

English

English  中文简体

中文简体