HOME / NEWS / Industry News / Why Cleanroom Swabs Are Essential in Controlled Environments

In cleanroom environments, controlling the concentration of particles, microorganisms, and chemical contaminants is the core objective. Cleanroom Swabs are indispensable tools in the daily maintenance and operational processes of cleanrooms, enabling critical tasks such as equipment cleaning, sample collection, and residue detection under strict cleanliness standards.

1. Preventing Particle Contamination

Any uncontrolled particles in a cleanroom can lead to product defects or deviations in experimental results. The low-linting property of Cleanroom Swabs significantly reduces the risk of secondary contamination.

- Low Linting Rate: High-quality Cleanroom Swabs typically have a linting rate lower than 0.1 mg/m², suitable for ISO 5 and higher cleanrooms.

- Surface Cleanliness: Cleaning tips are processed by ultrasonic cutting or heat sealing to minimize fiber shedding at the edges.

2. Precision Cleaning and Sampling

Compared with ordinary cotton swabs, Cleanroom Swabs have more precise head designs, allowing them to clean deep into micro-gaps or hard-to-reach component surfaces such as microelectronic parts, optical lenses, and pharmaceutical equipment interiors.

Feature Comparison

| Feature | Cleanroom Swabs | Ordinary Cotton Swabs |

|---|---|---|

| Fiber Shedding Rate | Very low (<0.1 mg/m²) | High (>0.5 mg/m²) |

| Chemical Resistance | Compatible with many solvents and alcohols | Easily degraded by solvents |

| Absorption Ability | High absorption, quick release | Slow absorption, uneven release |

| Applicable Cleanroom Level | ISO 3–ISO 8 | No cleanroom standards |

3. Compliance with Cleanroom Regulations

International standards (such as ISO 14644 and GMP) require the use of validated cleaning tools in cleanrooms. Cleanroom Swabs are manufactured, processed, and packaged in accordance with cleanroom requirements, with features such as:

- Sterilized by gamma irradiation or ethylene oxide

- Individually sealed to avoid cross-contamination

- ESD-safe design for static control needs

4. Improving Production and Testing Efficiency

In industries such as pharmaceuticals, semiconductors, and biotechnology, Cleanroom Swabs are used not only for cleaning but also for environmental monitoring and microbiological testing. Their stable performance helps reduce downtime, lower rework rates, and improve overall production efficiency.

Main Types and Material Composition of Cleanroom Swabs

The type and material composition of Cleanroom Swabs directly determine their cleaning efficiency, chemical compatibility, and application range in cleanroom environments. Variations in tip material, handle material, and size/shape make different Cleanroom Swabs suitable for different cleanroom grades and operational needs.

1. Classification by Tip Material

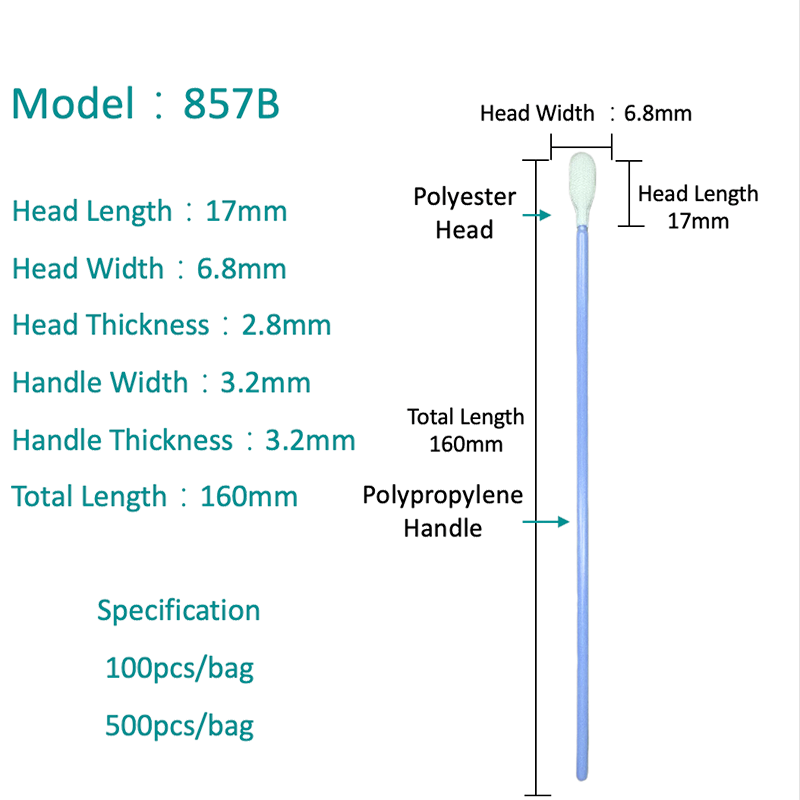

1. Polyester Fiber

Features: Low particle release, solvent-resistant, high abrasion resistance

Applications: Optical equipment cleaning, electronics maintenance, pharmaceutical equipment wiping

Drawback: Lower absorption than foam, but smooth cleaning surface

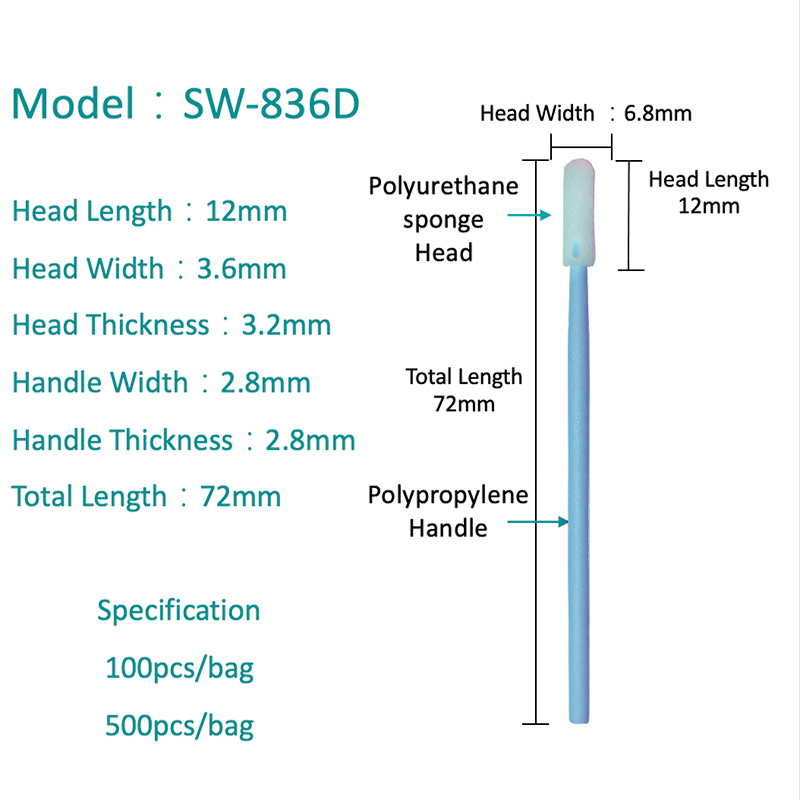

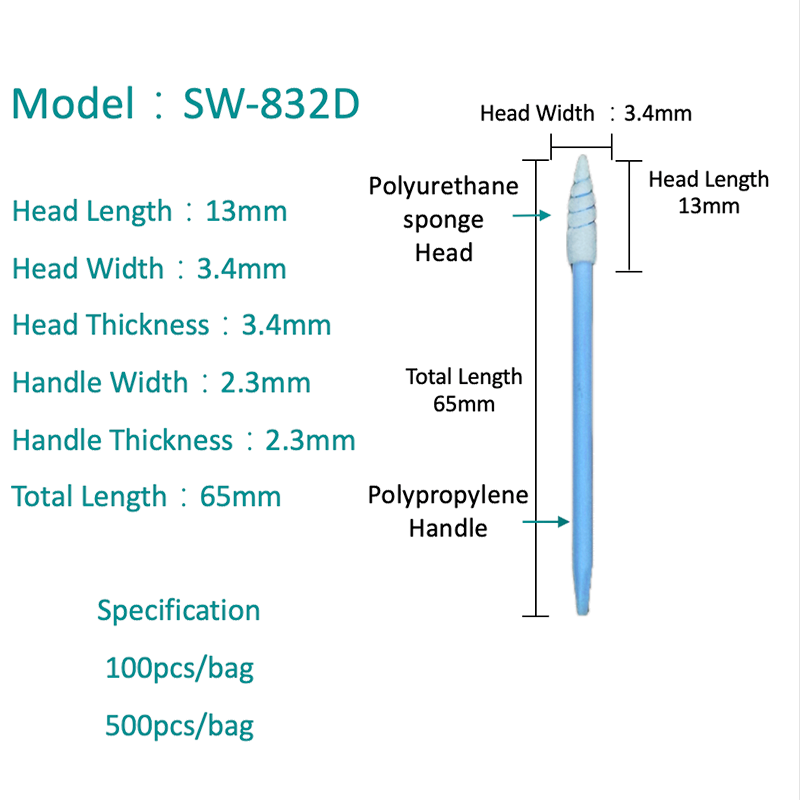

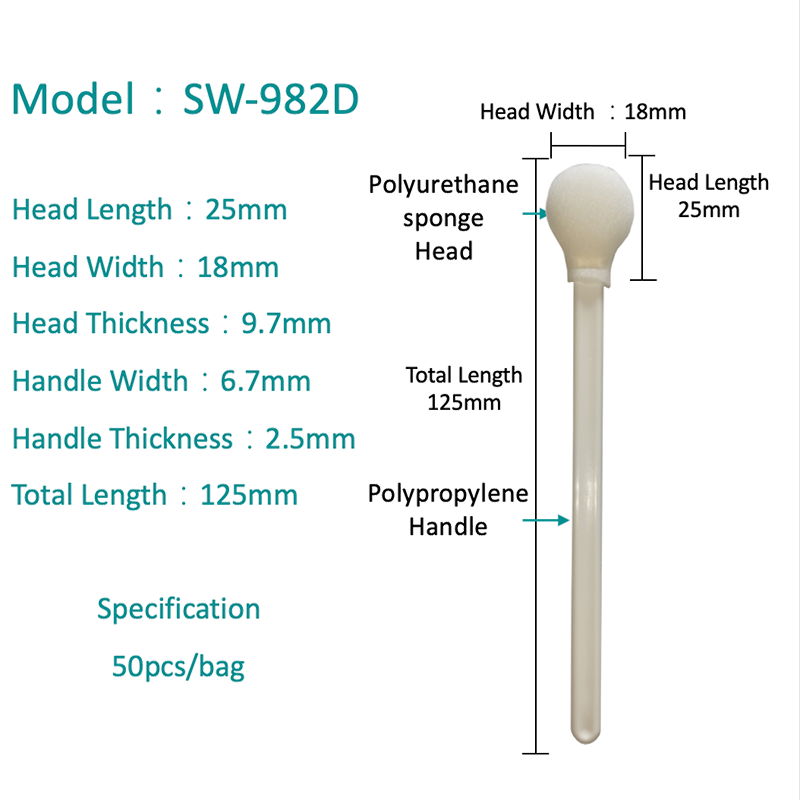

2. Polyurethane Foam

Features: Strong absorption capacity, softness, suitable for irregular surfaces

Applications: Liquid sampling, solvent application, equipment crevice cleaning

Drawback: Slightly lower abrasion resistance than polyester

3. Microfiber

Features: Exceptional adsorption capability, can capture submicron particles

Applications: High-precision optical lenses, sensors, clean glass panels

Drawback: Lower solvent resistance in some cases

4. Cotton

Features: Natural fiber, high absorption, low cost

Applications: Non-critical areas or primary cleaning

Drawback: High linting rate, not suitable for high-grade cleanrooms

2. Classification by Handle Material

- Polypropylene (PP) – Lightweight, chemically resistant

- Nylon – Strong flexibility, suitable for narrow space operations

- Stainless Steel – Autoclavable, ideal for special industrial environments

3. Common Types and Parameter Comparison

| Type | Material | Absorption (mL/g) | Chemical Resistance | Linting Rate (mg/m²) | Suitable Cleanroom Level |

|---|---|---|---|---|---|

| Polyester Fiber | Polyester | 4–6 | High | <0.1 | ISO 3–ISO 8 |

| Foam | PU Foam | 8–12 | Medium | <0.2 | ISO 5–ISO 8 |

| Microfiber | Microfiber | 7–10 | Medium | <0.15 | ISO 3–ISO 7 |

| Cotton | Cotton | 10–15 | Low | >0.5 | ISO 7–ISO 8 |

4. Material Selection Recommendations

- High-grade cleanrooms (ISO 3–ISO 5): Choose polyester or microfiber tips for low linting and high cleanliness.

- Medium-to-low grade cleanrooms (ISO 6–ISO 8): Foam and some cotton types can meet requirements but linting must be monitored.

- Special chemical environments: Select polyester or nylon handles with high solvent resistance to prevent degradation.

The Ultimate Guide to Cleanroom Swabs: Types, Uses, and Selection Criteria

Cleanroom Swabs are essential tools for cleaning, sampling, and inspection in cleanrooms and controlled environments. Different Cleanroom Swabs vary in material, absorption capacity, chemical resistance, and linting rate. Choosing the right one can significantly improve cleaning efficiency and reduce the risk of contamination.

1. Types of Cleanroom Swabs

Based on the tip material, Cleanroom Swabs can be divided into polyester, foam, microfiber, and cotton types. Each type is suited for different applications depending on required cleanliness, chemical resistance, and absorbency.

2. Common Uses

- Precision cleaning of sensitive components

- Application of solvents or adhesives

- Removal of residues in hard-to-reach areas

- Microbiological and particle sampling

3. Selection Criteria

When choosing a Cleanroom Swab, consider:

- Cleanroom Class: Higher classes require lower linting materials

- Chemical Compatibility: Ensure material is resistant to your cleaning solvents

- Absorbency: Match to the cleaning or application task

- ESD Requirements: Use ESD-safe swabs for electronics

| Material | Absorbency | Chemical Resistance | Linting | Typical Cleanroom Class |

|---|---|---|---|---|

| Polyester | Medium | High | Low | ISO 3–5 |

| Foam | High | Medium | Low | ISO 5–8 |

| Microfiber | High | Medium | Very Low | ISO 3–7 |

| Cotton | Very High | Low | High | ISO 7–8 |

How to Choose the Right Cleanroom Swabs Based on Your Needs

Selecting the right Cleanroom Swabs involves understanding your operational requirements, cleanroom class, chemical environment, and target industry standards. Below is a practical approach incorporating the manufacturing capabilities and expertise of Suzhou Zhuojing Dust-free Technology Co., Ltd.

1. Determine Cleanroom Class

Choose swabs with a linting rate and cleanliness level appropriate for your cleanroom. For ISO 3–5 environments, select polyester or microfiber swabs; for ISO 6–8, foam or selected cotton swabs may suffice.

2. Match Chemical Compatibility

Ensure swab materials can withstand the solvents or disinfectants used. Polyester is ideal for strong solvents, while foam offers good compatibility with alcohols and mild solvents.

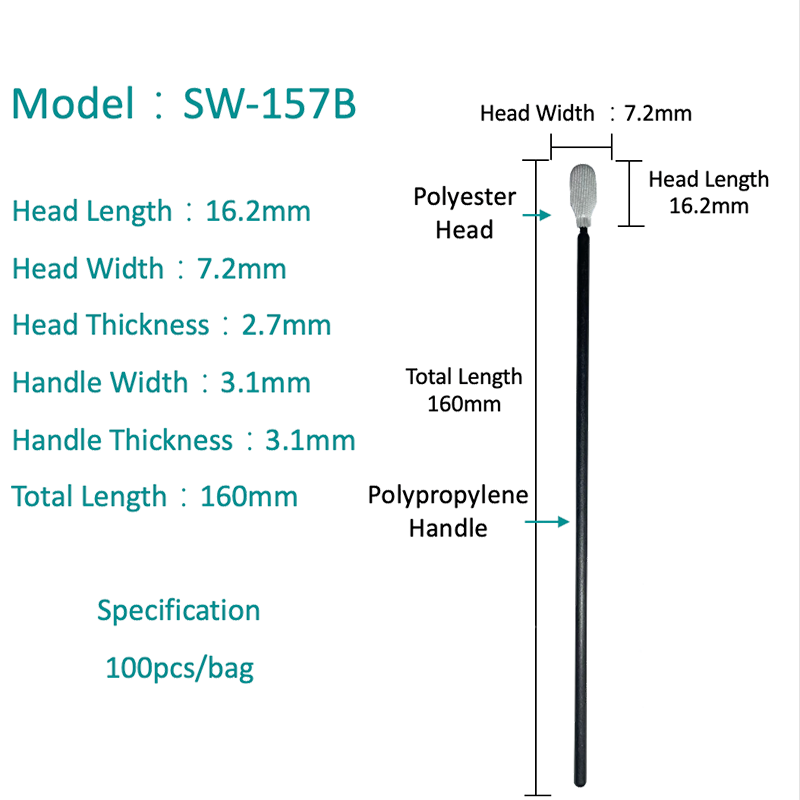

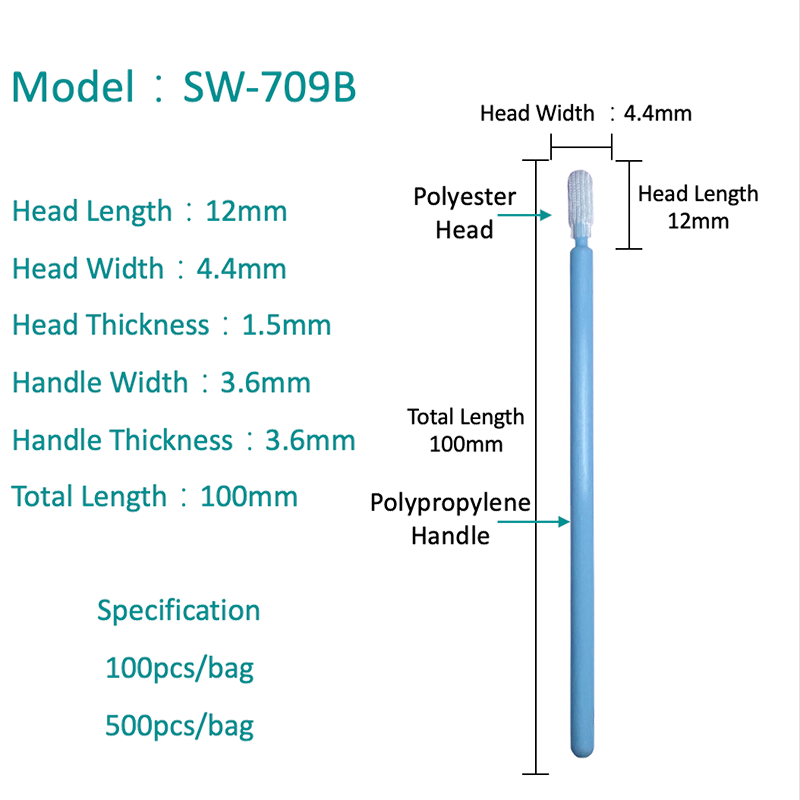

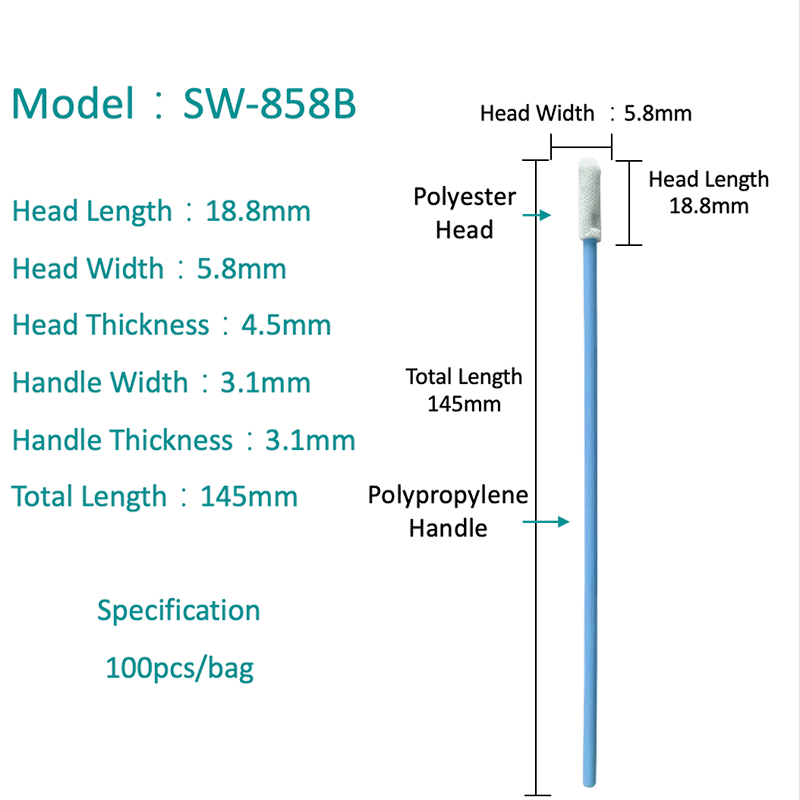

3. Evaluate Tip Shape and Size

Different tasks require different tip designs: pointed tips for fine crevices, paddle tips for large surfaces, and round tips for general cleaning.

4. Consider Manufacturer Capabilities

Suzhou Zhuojing Dust-free Technology Co., Ltd. operates cleanrooms ranging from Class 10 to Class 1000 and uses ultra-pure water with a purity of up to 18 mega-ohm for cleaning. Products are vacuum-sealed to maintain cleanliness. Their swabs are produced with advanced dust-free technology, ensuring they meet strict cleanliness standards.

5. Applications by Industry

- Semiconductors & Microelectronics: ESD-safe polyester or microfiber swabs

- Pharmaceuticals: Sterile foam or microfiber swabs

- Aerospace: Low-linting polyester swabs

- Precision Instruments: Microfiber swabs for submicron particle removal

6. Parameter-Based Recommendation Table

| Requirement | Recommended Material | Reason |

|---|---|---|

| Highest Cleanliness | Polyester / Microfiber | Low linting, smooth surface |

| High Absorption | Foam | Large liquid retention and quick release |

| Solvent Resistance | Polyester | Resistant to strong solvents |

| Cost Efficiency | Cotton | Low cost for non-critical areas |

English

English  中文简体

中文简体