HOME / NEWS / Industry News / The Ultimate Guide to Cleanroom Swabs: Types, Uses, and Selection Criteria

Understanding cleanroom swab materials for optimal performance

When selecting cleanroom swab materials, it's crucial to understand how different options affect performance in controlled environments. The material composition directly impacts particle shedding, chemical compatibility, and absorption capabilities.

Common materials used in cleanroom swabs

Manufacturers like Suzhou Zhuojing Dust-free Technology Co., Ltd. typically offer several material options:

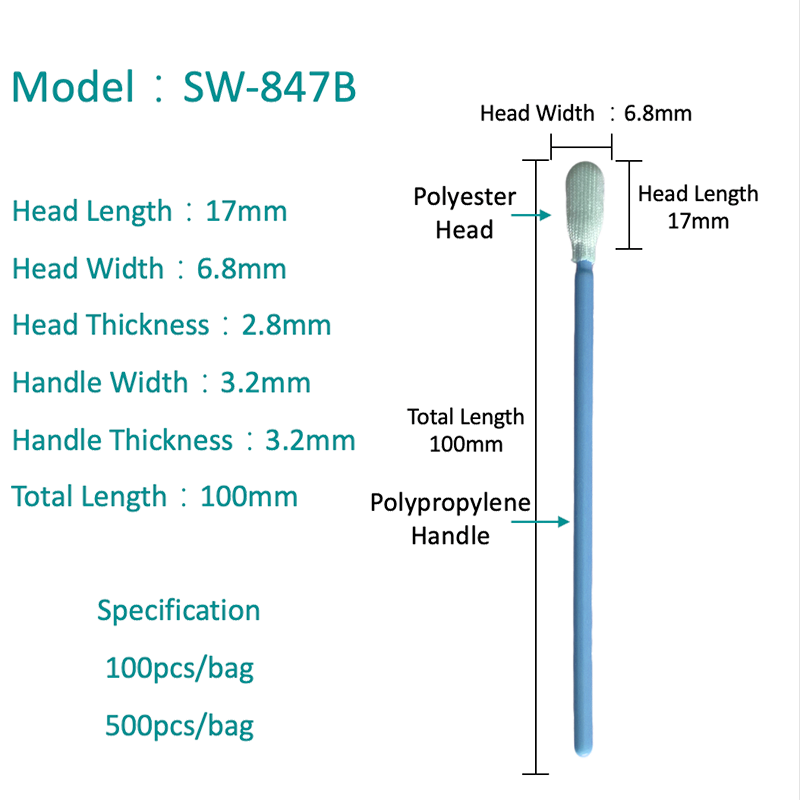

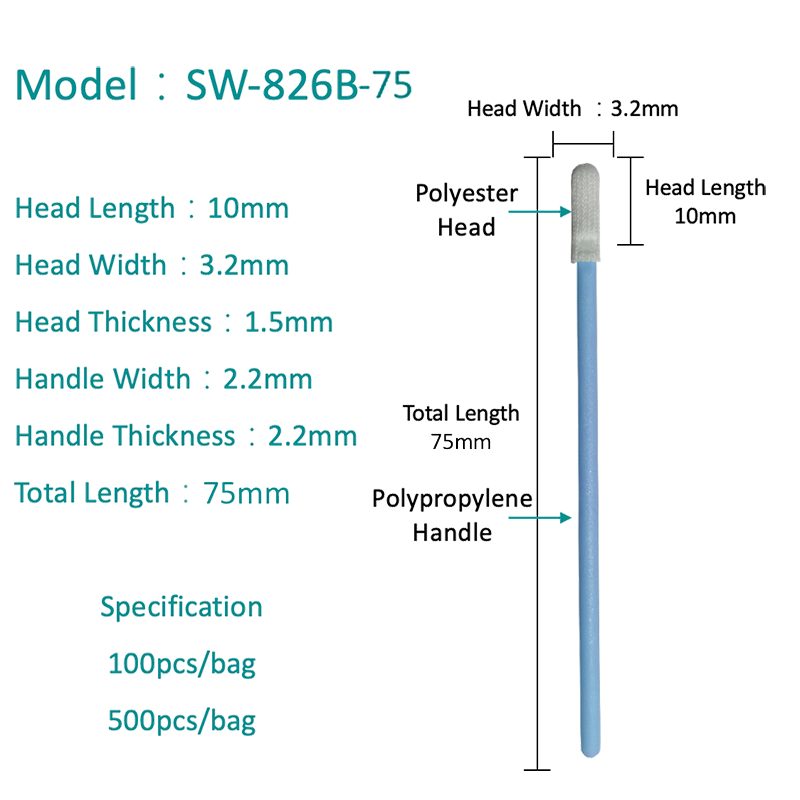

- Polyester: Provides excellent chemical resistance and low particulate generation

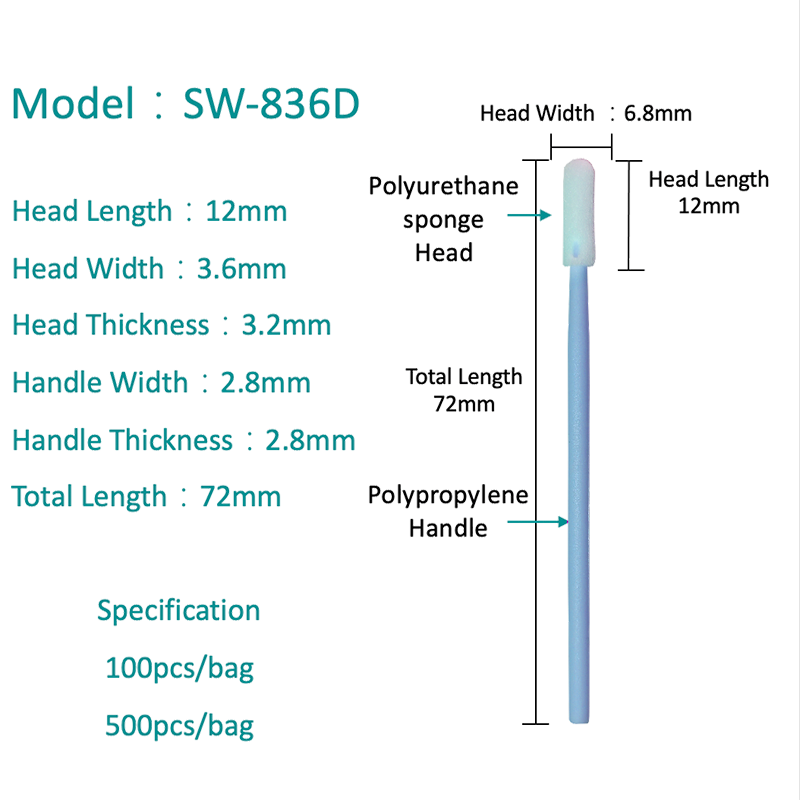

- Polyurethane: Offers superior absorbency for liquid applications

- Foam: Delivers exceptional particle capture and surface conformity

- Microfiber: Ideal for precision cleaning of delicate surfaces

- Rayon: Cost-effective option for general cleaning applications

Material comparison table

| Material | Particle Shedding | Chemical Resistance | Absorbency |

|---|---|---|---|

| Polyester | Low | Excellent | Medium |

| Polyurethane | Medium | Good | High |

| Foam | Very Low | Excellent | High |

| Microfiber | Low | Good | Medium |

| Rayon | Medium | Fair | Medium |

Suzhou Zhuojing Dust-free Technology Co., Ltd. specializes in developing advanced cleanroom swab materials that meet stringent industry requirements. Their engineering team focuses on creating solutions that minimize particle generation while maintaining excellent cleaning performance.

How to choose sterile cleanroom swabs for pharmaceutical applications

The pharmaceutical industry requires exceptionally high standards when it comes to sterile cleanroom swabs for pharmaceutical applications. These swabs must meet rigorous contamination control requirements while effectively cleaning sensitive equipment and surfaces.

Critical considerations for pharmaceutical-grade swabs

- Sterilization method compatibility (gamma radiation, ETO, or autoclave)

- Endotoxin levels below detectable limits

- Validation documentation including DOP testing

- Material compatibility with cleaning solvents

- Packaging integrity to maintain sterility

Sterilization method comparison

| Method | Effectiveness | Material Limitations | Residual Concerns |

|---|---|---|---|

| Gamma Radiation | High | May affect some plastics | None |

| ETO | High | None | Requires aeration |

| Autoclave | High | Heat-sensitive materials | Moisture retention |

As a specialized manufacturer, Suzhou Zhuojing Dust-free Technology Co., Ltd. provides customized solutions for sterile cleanroom swabs for pharmaceutical applications, offering comprehensive validation support and documentation to meet regulatory requirements.

The importance of low-lint cleanroom swabs for electronics manufacturing

In electronics manufacturing, low-lint cleanroom swabs for electronics manufacturing play a critical role in maintaining product quality and reliability. Even microscopic particles can cause significant issues in sensitive electronic components.

Key features of effective electronics cleaning swabs

- Ultra-low particulate generation (typically <0.5 particles/cm²)

- ESD-safe materials to prevent static discharge

- Precision tips for accessing small components

- Chemical compatibility with electronics cleaning solvents

- Non-abrasive surfaces to prevent damage

Electronics cleaning challenges and solutions

| Challenge | Conventional Swab | Low-Lint Solution |

|---|---|---|

| Particle Contamination | High risk | Minimal risk |

| Static Discharge | Possible | Protected |

| Precision Cleaning | Limited | Optimized |

Suzhou Zhuojing Dust-free Technology Co., Ltd. has developed specialized low-lint cleanroom swabs for electronics manufacturing that meet the exacting standards of semiconductor and microelectronics production environments.

Best practices for cleanroom swab handling and disposal procedures

Proper cleanroom swab handling and disposal procedures are essential to maintain contamination control and ensure cleaning effectiveness. Even the highest quality swabs can become contamination sources if handled improperly.

Comprehensive handling protocol

- Always wear appropriate cleanroom gloves when handling swabs

- Inspect packaging integrity before use

- Remove only the number of swabs needed immediately

- Avoid touching non-target surfaces with swab tips

- Use single-direction wiping motions when cleaning

Disposal method comparison

| Disposal Method | Appropriate For | Contamination Risk |

|---|---|---|

| Sealed Waste Containers | General cleanroom waste | Low |

| Hazardous Waste Bins | Chemical-contaminated swabs | Medium |

| Biohazard Containers | Sterile applications | High |

Suzhou Zhuojing Dust-free Technology Co., Ltd. provides detailed handling guidelines with their products and can offer customized cleanroom swab handling and disposal procedures training for client facilities.

Comparing foam tip vs polyester tip cleanroom swabs for different applications

The debate between foam tip vs polyester tip cleanroom swabs requires careful consideration of application requirements. Each material offers distinct advantages depending on the cleaning task.

Performance characteristics comparison

- Foam tips excel in particle entrapment and liquid absorption

- Polyester tips provide superior chemical resistance

- Foam conforms better to irregular surfaces

- Polyester maintains structure better for precision cleaning

- Foam typically has lower particulate generation

Application suitability matrix

| Application | Foam Tip | Polyester Tip |

|---|---|---|

| Optics Cleaning | Excellent | Good |

| Solvent Application | Good | Excellent |

| Particle Removal | Excellent | Good |

| Precision Cleaning | Good | Excellent |

Suzhou Zhuojing Dust-free Technology Co., Ltd. offers both foam tip vs polyester tip cleanroom swabs in various configurations, with technical support to help customers select the optimal solution for their specific applications.

Advancements in cleanroom swab technology

The cleanroom swab industry continues to evolve with new technologies and improved materials. Manufacturers like Suzhou Zhuojing Dust-free Technology Co., Ltd. are at the forefront of these developments.

Emerging trends in cleanroom swab design

- Nanofiber technology for ultra-fine particle capture

- Smart swabs with indicator properties

- Biodegradable materials for environmental sustainability

- Improved ergonomic designs for better control

- Enhanced packaging for better sterility maintenance

As a research-driven company, Suzhou Zhuojing Dust-free Technology Co., Ltd. continuously invests in developing next-generation cleanroom swab solutions that address evolving industry challenges while maintaining the highest quality standards.

English

English  中文简体

中文简体