HOME / NEWS / Industry News / The Ultimate Guide to Foam Swab Sticks: Uses, Types, and Benefits

What Are Foam Swab Sticks and Their Primary Applications

Foam swab sticks, also known as foam-tipped applicators, are versatile tools consisting of a foam head attached to a stick or rod. These specialized cleaning and application tools serve numerous purposes across various industries and household applications. The foam swab sticks are particularly valued for their absorbency, soft texture, and ability to clean delicate surfaces without causing scratches or damage.

Common Uses of Foam Swab Sticks

- Precision cleaning of electronic components and circuit boards

- Application of adhesives, lubricants, or cleaning solutions in controlled amounts

- Medical and laboratory sample collection and application

- Art restoration and conservation work

- Cosmetic application and touch-ups

- Industrial equipment maintenance

Why Choose Foam Over Other Materials?

When comparing foam swabs to cotton or other materials, several advantages become apparent. Foam offers superior absorbency and controlled liquid release, unlike cotton which may leave fibers behind. The table below highlights key differences:

| Feature | Foam Swabs | Cotton Swabs |

|---|---|---|

| Absorbency | High, with controlled release | Moderate, with uneven release |

| Lint Production | Minimal to none | Can leave fibers |

| Surface Safety | Safe for delicate surfaces | May scratch sensitive materials |

| Chemical Resistance | Good (depending on foam type) | Limited |

best foam swab sticks for electronics cleaning

When it comes to cleaning sensitive electronic components, not all foam swab sticks are created equal. The best foam swab sticks for electronics cleaning must meet specific criteria to ensure they effectively remove contaminants without damaging delicate circuits or leaving residue.

Essential Features for Electronics Cleaning

- Anti-static properties to prevent electrostatic discharge

- High-purity foam that won't leave chemical residues

- Precision tips for reaching small spaces

- Chemical-resistant materials for use with various solvents

- Non-abrasive surfaces that won't scratch components

How to Properly Clean Electronics with Foam Swabs

The process of cleaning electronics requires careful attention to detail. First, power off and unplug the device whenever possible. Select an appropriate cleaning solution - isopropyl alcohol (90% or higher) is commonly recommended. Dip the foam tip lightly into the solution, then gently wipe the surface using minimal pressure. For stubborn contaminants, allow the solution to sit briefly before wiping. Always work from the center outward when cleaning connectors, and use a dry foam swab to remove any remaining moisture.

disposable foam swab sticks for medical use

In medical and laboratory settings, disposable foam swab sticks for medical use play critical roles in sample collection, wound care, and various diagnostic procedures. These specialized swabs must meet stringent quality and sterility standards.

Medical Applications of Foam Swabs

- Wound cleaning and debridement

- Application of topical medications

- Collection of biological samples for testing

- Pre-surgical skin preparation

- Dental procedures and oral care

Key Considerations for Medical-Grade Foam Swabs

Medical professionals must evaluate several factors when selecting foam swabs for clinical use. The foam material must be non-toxic and non-irritating, with appropriate absorbency for the intended application. Sterility is paramount for many uses, requiring gamma irradiation or other sterilization methods. The swab handle should be sturdy yet lightweight, often made from medical-grade plastics or paper. Importantly, medical swabs must be single-use only to prevent cross-contamination.

how to choose the right foam swab stick size

Selecting the how to choose the right foam swab stick size depends on multiple factors including the application, working space constraints, and required precision. Understanding size variations and their appropriate uses ensures optimal performance.

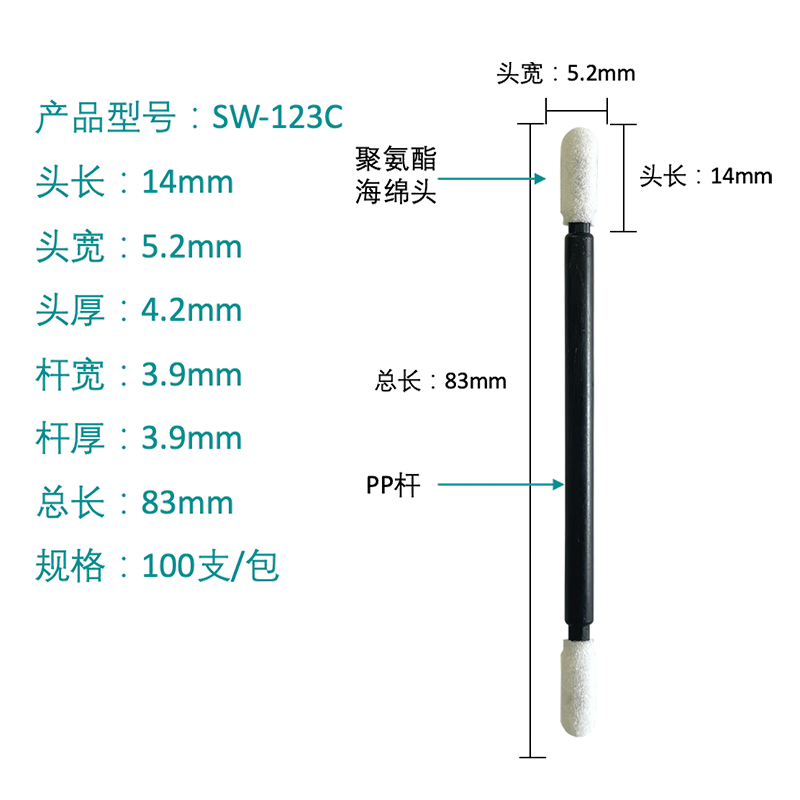

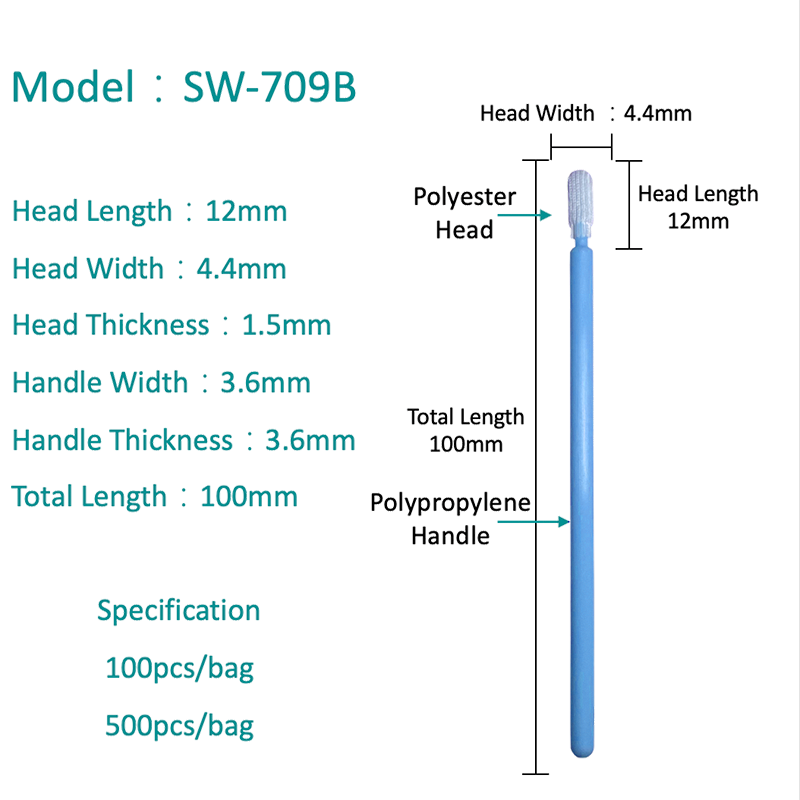

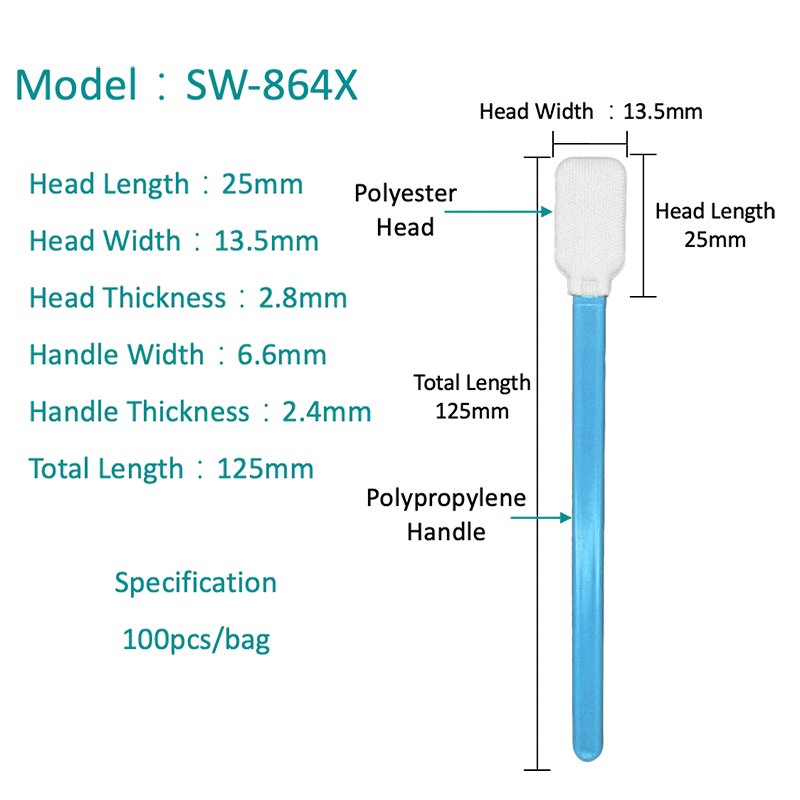

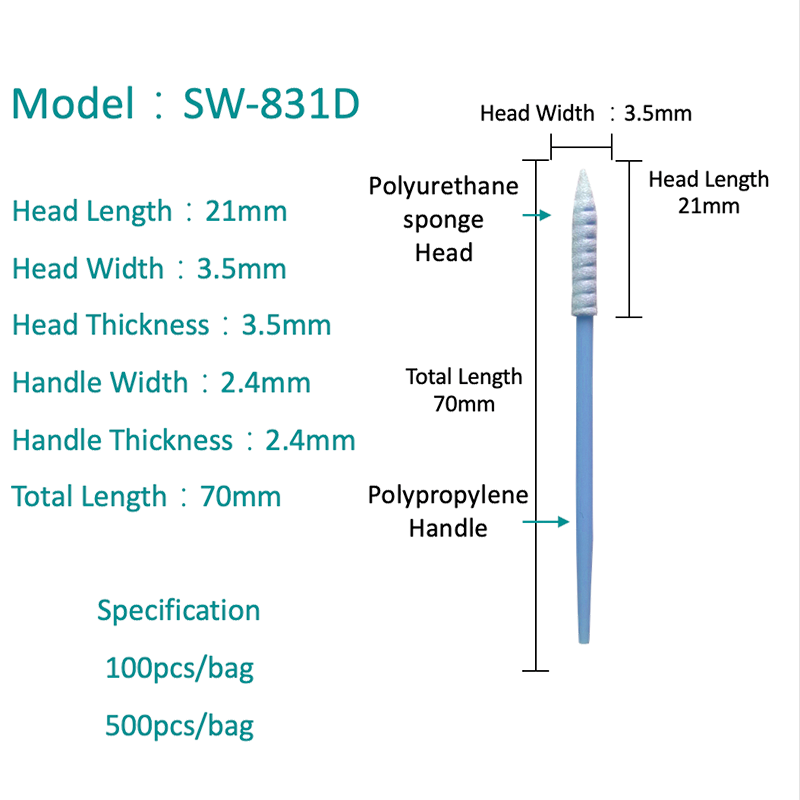

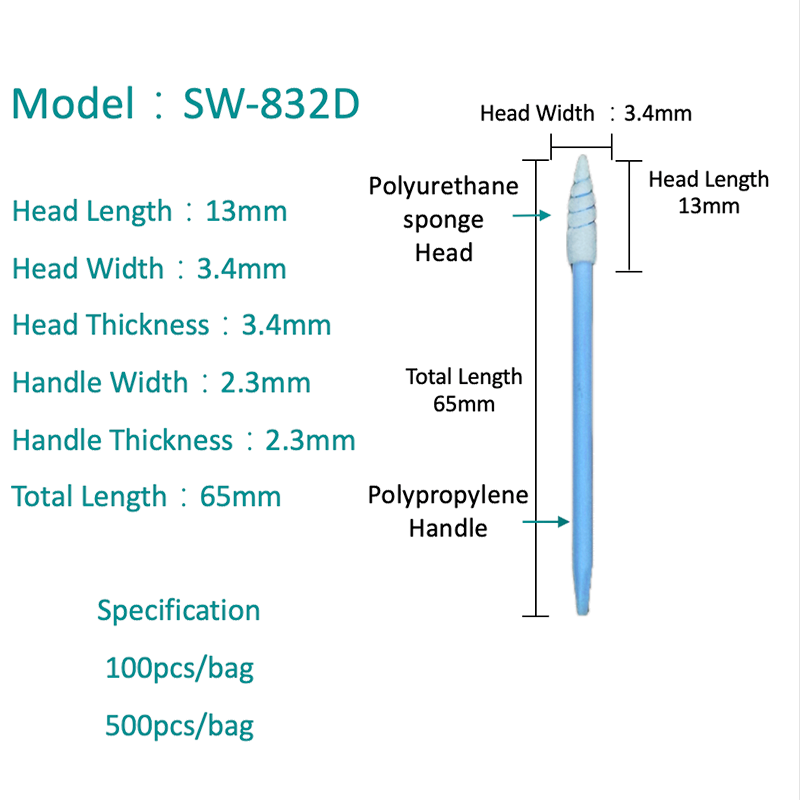

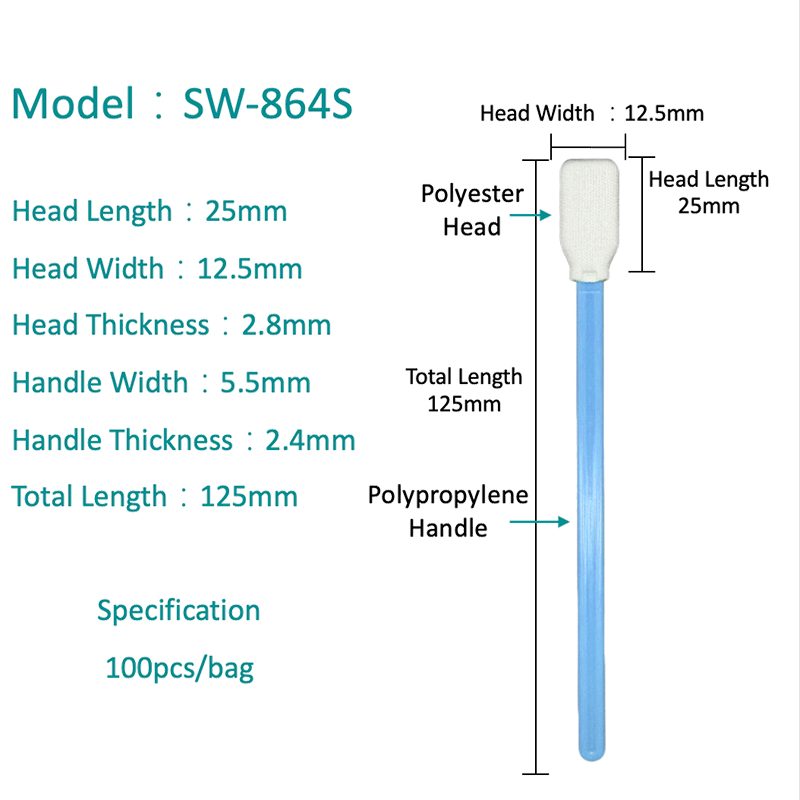

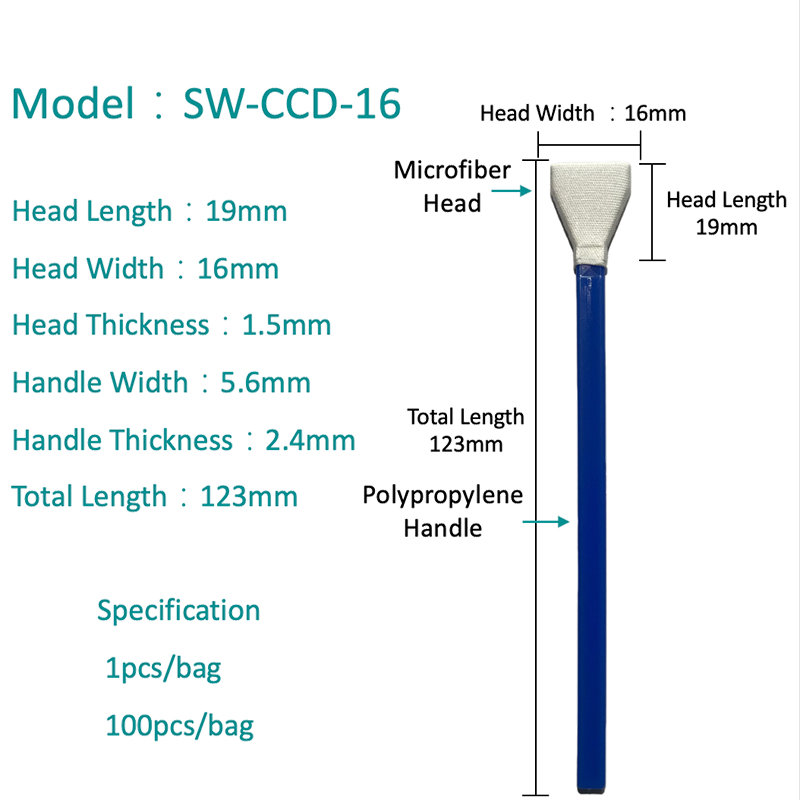

Understanding Foam Swab Dimensions

Foam swab sticks vary in three primary dimensions: foam head size, stick length, and stick diameter. Head sizes typically range from 1mm for ultra-fine applications to 25mm for broad coverage. Stick lengths commonly vary between 3 inches (75mm) for precision work to 12 inches (300mm) for hard-to-reach areas. Stick diameter affects rigidity, with thicker sticks (3-5mm) offering more control for pressure applications.

Size Selection Guidelines

| Application Type | Recommended Head Size | Recommended Length |

|---|---|---|

| Electronics cleaning | 3-8mm | 100-150mm |

| Medical wound care | 10-15mm | 150-200mm |

| Industrial equipment | 15-25mm | 200-300mm |

| Art restoration | 2-6mm | 75-150mm |

foam swab sticks vs cotton swabs for precision cleaning

The debate between foam swab sticks vs cotton swabs for precision cleaning involves multiple factors including material properties, cleaning effectiveness, and application requirements. Each type has distinct advantages depending on the specific cleaning task.

Material Composition Comparison

Foam swabs typically use polyurethane or other synthetic foams that offer consistent density and pore structure. Cotton swabs use natural fibers that can vary in density and may contain impurities. This fundamental difference affects several performance characteristics:

- Foam provides more uniform liquid absorption and release

- Cotton may absorb more liquid but releases it less controllably

- Foam maintains its shape better during use

- Cotton may fray or leave fibers on cleaned surfaces

Performance in Precision Cleaning Applications

| Cleaning Aspect | Foam Swabs | Cotton Swabs |

|---|---|---|

| Fiber Shedding | Minimal | Moderate to High |

| Chemical Resistance | Excellent | Good (varies by treatment) |

| Surface Contact | Consistent | Variable |

| Delicate Surface Safety | High | Moderate |

sterile foam swab sticks for laboratory applications

In laboratory environments, sterile foam swab sticks for laboratory applications are essential tools for maintaining contamination-free conditions, precise sample collection, and controlled reagent application.

Critical Laboratory Uses

- Microbiological sampling from surfaces or equipment

- Application of reagents in diagnostic tests

- Cell culture maintenance and manipulation

- Cleaning optical instruments and sensitive lab equipment

- DNA sample collection for genetic testing

Sterility and Material Requirements

Laboratory-grade foam swabs must meet rigorous standards. The foam material should be inert and non-reactive with common laboratory chemicals. Sterilization methods must be validated to ensure complete microbial elimination without compromising material properties. Packaging should maintain sterility until use and allow for aseptic removal. Many laboratories require documentation of sterility assurance levels and material certifications.

Environmental Considerations and Proper Disposal

As with all disposable products, environmental impact is an important consideration for foam swab sticks. Understanding proper disposal methods and emerging eco-friendly alternatives helps users make responsible choices.

Disposal Guidelines by Application

- Medical/laboratory used swabs: Follow biohazard waste protocols

- Electronics cleaning swabs with solvents: Check local hazardous waste regulations

- General purpose used swabs: Typically can go in regular trash

Emerging Sustainable Alternatives

The industry is developing more environmentally friendly options including biodegradable foam materials and reusable handle systems with replaceable foam heads. While these alternatives currently represent a small portion of the market, their availability is increasing as sustainability concerns grow.

English

English  中文简体

中文简体