HOME / NEWS / Industry News / Do you know why Foam Tip Cleaning Swabs have become the first choice for precision cleaning?

1. Introduction

With the continuous development of science and technology, especially in the fields of electronics, medical and optics, higher requirements are placed on the precision cleaning of products and equipment. Precision cleaning not only directly affects the performance and service life of the equipment, but also affects the stability of production efficiency and product quality. In many high-end manufacturing and maintenance processes, fine dust, oil and even tiny particles may cause serious failures or performance degradation. Therefore, choosing the right cleaning tool becomes the key.

Traditional cleaning tools such as cotton swabs and brushes, although they perform well in daily applications, have the disadvantages of easy hair loss, incomplete cleaning and easy secondary pollution when facing increasingly sophisticated and complex cleaning needs. Foam Tip Cleaning Swabs came into being. With its special foam material and scientific design structure, it has gradually become the preferred tool for precision cleaning in the fields of industry and scientific research.

2. Material and structural advantages of Foam Tip Cleaning Swabs

2.1 Characteristics of Foam Head Material

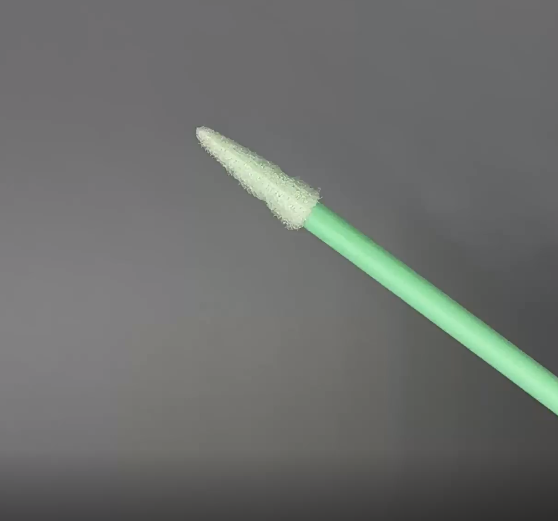

The core advantage of Foam Tip Cleaning Swabs lies in its foam material. High-density polyurethane foam is usually used, which has excellent adsorption and elasticity. Its open cell structure enables it to effectively capture and fix tiny particles and liquid pollutants, and it does not easily shed fibers like cotton materials. In addition, the foam material has good chemical resistance and can be used with a variety of solvents and detergents to meet diverse cleaning needs.

2.2 Structural design improves cleaning effect

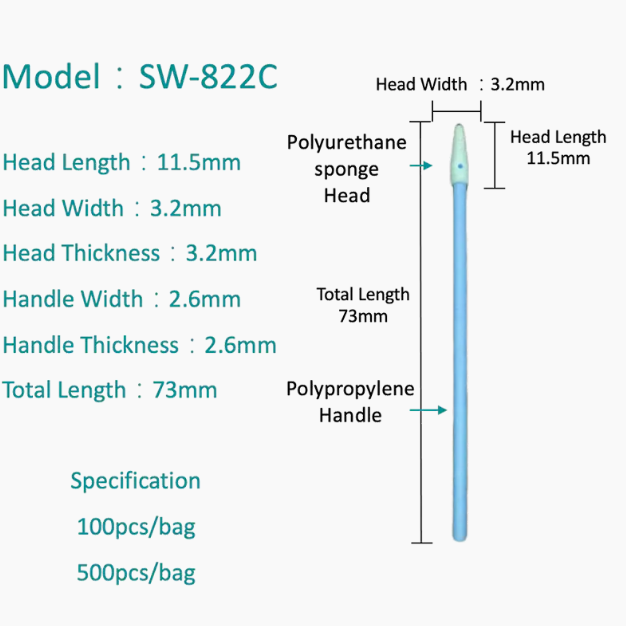

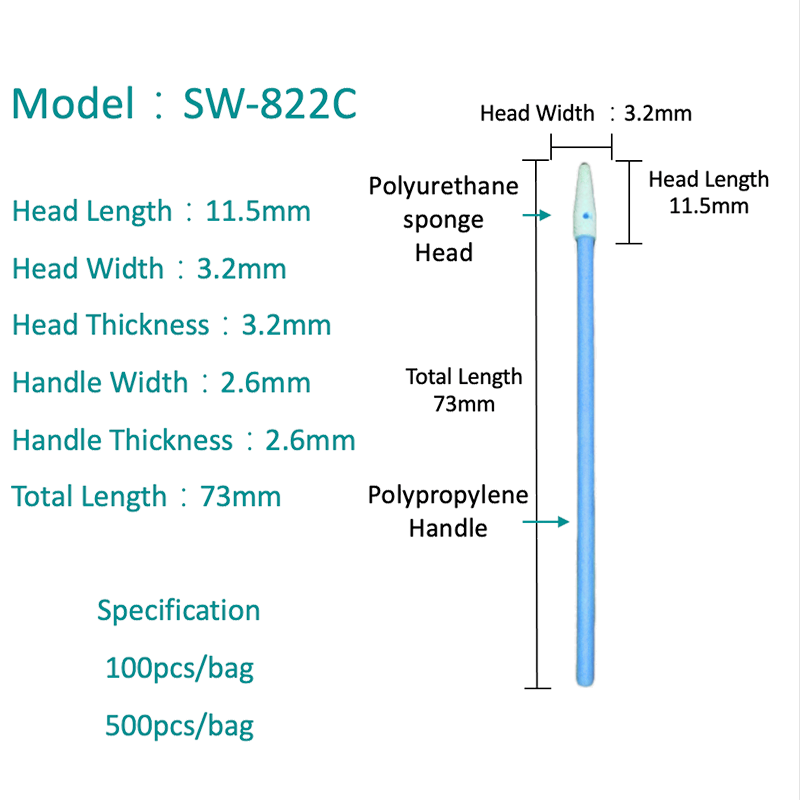

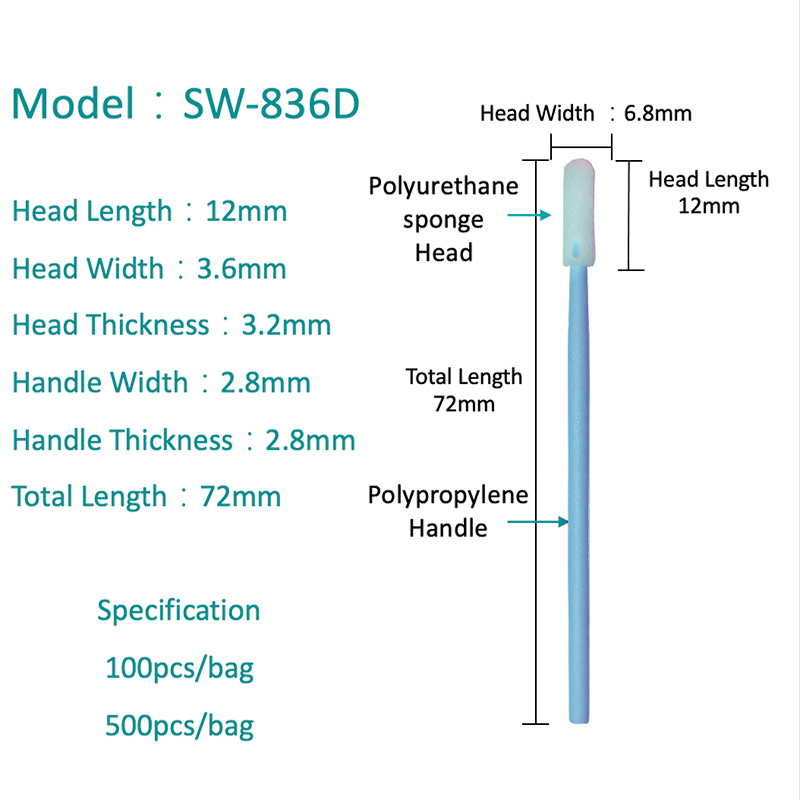

In addition to the material, Foam Tip Cleaning Swabs are also optimized in shape and size design. The head is usually conical, spherical or flat, which is convenient for penetrating into the corners of narrow or complex structures. The soft foam head can easily adapt to irregular surfaces to avoid scratching or damaging precision components. The rod body is designed to be light and sturdy, which is convenient for operators to control accurately and improve cleaning efficiency and effect.

2.3 Adaptability of materials to sensitive surfaces

In the cleaning of highly sensitive surfaces such as medical equipment, optical lenses and semiconductor devices, any slight damage or residue may have serious consequences. The non-abrasive material and soft structure of the foam head cleaning rod greatly reduce the risk of mechanical impact on these sensitive surfaces. At the same time, the antistatic properties of the foam material can also reduce dust adsorption and ensure the cleanliness of the surface after cleaning.

3. Key applications of Foam Tip Cleaning Swabs in various industries

3.1 Electronic manufacturing and maintenance

The electronics industry has extremely strict requirements for cleaning. Tiny dust and grease will affect the quality of circuit board welding and the performance of electronic components. Foam Tip Cleaning Swabs can penetrate into tiny gaps and effectively remove solder residues and oil stains to ensure the stable operation of electronic products. Its good chemical compatibility also allows it to be used with various electronic-grade cleaning agents to meet the multiple needs of high-end electronic manufacturing and maintenance.

3.2 Medical devices and laboratory environments

Medical devices have extremely high standards for sterile and clean environments. Foam tip cleaning sticks are suitable for daily maintenance of surgical instruments, microscope lenses and laboratory equipment. Its non-woven material properties prevent cross-contamination while taking into account the tolerance of disinfectants, and it is an important auxiliary tool to ensure medical safety. In laboratories, especially for the cleaning of biological and chemical analysis equipment, such cleaning sticks are also widely used to ensure the accuracy of experimental data.

3.3 Optical equipment and precision instruments

Optical instruments such as telescopes, camera lenses and laser equipment require extremely clean optical surfaces. Traditional tools are prone to scratches or fiber particles, but the soft head and high adsorption of the foam tip cleaning stick effectively avoid such problems. It can accurately remove dust and oil from the lens while ensuring the integrity and performance of the optical components.

3.4 Applications in the automotive and aviation industries

Precision cleaning of mechanical parts and instruments is also critical in the automotive and aviation manufacturing industries. Foam tip cleaning sticks provide an efficient and safe cleaning method when cleaning engine components, sensors and electronic control units. Its compatibility with a variety of cleaning agents makes it adaptable to complex industrial environment requirements, effectively improving maintenance quality and equipment reliability.

4. The role of Foam Tip Cleaning Swabs in improving cleaning efficiency

4.1 Effective removal of dust and pollutants

Thanks to the high adsorption of the foam tip, Foam Tip Cleaning Swabs can penetrate into tiny gaps and quickly capture and fix fine particles and pollutants. This feature is particularly important when cleaning electronic components and high-precision machinery, greatly reducing the risk of secondary contamination and improving the overall cleaning quality.

4.2 Characteristics of reducing cross contamination

Cross contamination is a common problem in cleaning operations. Foam Tip Cleaning Swabs use a disposable design and combine it with a specific material formula to reduce the transfer of pollutants during the cleaning process. At the same time, it is easy to package and store before and after use, ensuring the hygiene and safety of the cleaning stick, and is suitable for occasions with strict requirements for a clean environment.

4.3 Improve the convenience and speed of cleaning operations

Traditional cleaning tools are cumbersome and time-consuming to operate when faced with complex structures. The foam head cleaning stick is light and easy to hold, and with the diversified design of the head, operators can complete cleaning tasks quickly and accurately. Its excellent durability reduces the frequency of tool replacement and saves maintenance costs and time.

5. Comparative analysis with traditional cleaning tools

5.1 Differences and advantages with cotton swabs

As one of the most common cleaning tools, cotton swabs have disadvantages such as easy fiber shedding and excessive water absorption leading to detergent retention. In contrast, the foam head of Foam Tip Cleaning Swabs does not shed hair, can quickly release or absorb liquid, avoid residue and clogging problems, and the cleaning effect is more stable and safe.

5.2 Performance comparison with brushes

Although brushes can cover a large area, they are often unable to clean fine spaces and sensitive parts, and the bristles may scratch the surface. Foam tip cleaning sticks are suitable for detail processing, and the material is softer, which can effectively reduce the risk of surface damage and improve the overall maintenance quality.

5.3 Performance differences in different cleaning environments

In extreme environments or special industries, such as dust-free rooms and clean rooms, traditional tools are prone to pollution risks. Foam tip cleaning sticks are more in line with the cleaning standards of strict environments due to their material stability and one-time use characteristics, ensuring that the cleanliness of the environment is not destroyed.

6. Environmental protection and safety characteristics of Foam Tip Cleaning Swabs

6.1 Environmental protection and recyclability of materials

Modern industry has increasing requirements for environmental protection. Foam Tip Cleaning Swabs mostly use environmentally friendly foam materials, which can be biodegraded or recycled, reducing the burden of industrial waste on the environment. In addition, some products use non-toxic and harmless formulas, which are in line with the concept of green manufacturing.

6.2 Safety for operators and the environment

The material is non-irritating and harmless to the operator's skin, avoiding health problems caused by contact with chemical residues. Good chemical resistance ensures that no harmful reactions occur when using cleaning agents, ensuring a safe working environment.

6.3 Relevant certifications that meet industry standards

High-quality Foam Tip Cleaning Swabs meet a number of international industry standards, such as electrostatic discharge (ESD) standards for the electronics industry and medical device cleaning specifications. Through strict testing and certification, it ensures that the product is suitable for various high-end cleaning applications.

Conclusion

Foam Tip Cleaning Swabs has become an indispensable tool for modern precision cleaning with its unique material advantages, design innovations and wide industry adaptability. It plays an important role in improving cleaning efficiency, ensuring equipment performance and extending service life. As the cleaning requirements of various industries continue to increase, Foam Tip Cleaning Swabs will surely show greater value in more fields and help the high-tech industry move towards a higher quality future.

English

English  中文简体

中文简体