HOME / NEWS / Industry News / The Ultimate Guide to Dacron Swabs: Selection, Applications, and Industry Standards

In the demanding world of precision manufacturing and scientific research, the choice of consumables is critical. Among these, the dacron swab stands out as a fundamental tool. Known for its excellent absorbency, low particle shedding, and chemical resistance, Dacron (a type of polyester) is the material of choice for countless critical cleaning and sampling applications. This guide delves deep into the specifics of Dacron swabs, providing professionals with the detailed information needed to make informed decisions and optimize their processes. As a specialized manufacturer, Suzhou Zhuojing Dust-free Technology Co., Ltd. leverages its expertise in cleanroom production to engineer Dacron swabs that meet the highest standards of purity and performance for industries ranging from semiconductors to pharmaceuticals.

Understanding Dacron Swabs: Material and Manufacturing Excellence

Dacron swabs are not simple cotton buds; they are precision-engineered tools. The fiber's inherent properties make it ideal for environments where contamination control is paramount.

Key Material Properties of Dacron

- Low Linting and Particle Generation: Dacron fibers are continuous filaments, resulting in significantly fewer loose fibers compared to natural materials like cotton.

- High Absorbency and Liquid Retention: The fibers efficiently wick and hold solvents, reagents, and contaminants.

- Excellent Chemical Compatibility: Dacron is resistant to a wide range of acids, alkalis, and solvents, ensuring swab integrity during use.

- Heat Resistance: Can withstand higher temperatures than many other swab materials, allowing for use in more processes.

Advanced Manufacturing in Controlled Environments

The performance of a dacron swab is heavily dependent on its manufacturing environment. At Suzhou Zhuojing, production occurs in certified cleanrooms (Class 10 to Class 1000) to prevent airborne contamination. The swabs undergo a rigorous cleaning process using 18 mega-ohm ultra-pure water and are then vacuum-sealed to guarantee cleanliness upon arrival at the customer's facility. This commitment to a controlled environment ensures that the swab itself does not become a source of particulate or ionic contamination, which is crucial for cleaning sensitive electronic components with dacron swabs.

Selecting the Right Dacron Swab for Your Application

Choosing the correct swab involves considering the handle material, tip shape, fabric purity, and the specific task. A mismatch can lead to ineffective cleaning or even damage.

Handle Material Comparison

The handle provides structure and determines chemical resistance. Polypropylene handles are cost-effective and resistant to many chemicals, making them suitable for general cleaning. For applications involving strong solvents or extreme temperatures, a high-purity dacron swab for medical device cleaning might require a more inert handle like molded polypropylene (PP) or even a glass-filled handle for added rigidity. The choice directly impacts the swab's durability and suitability for the task. For instance, when evaluating dacron vs foam swabs for precision cleaning, one must consider that while foam is excellent for planar surfaces, Dacron on a sturdy handle is superior for applying pressure in crevices.

| Handle Material | Key Properties | Ideal For |

| Polypropylene (PP) | Good chemical resistance, economical, flexible. | General wiping, light solvent use, non-critical cleaning. |

| Molded Polypropylene | More rigid, consistent shape, better solvent resistance. | Precision cleaning, repeated use with solvents, applying pressure. |

| Glass-Filled PP | High rigidity, minimal flex, excellent dimensional stability. | Applications requiring no flex, aggressive scrubbing. |

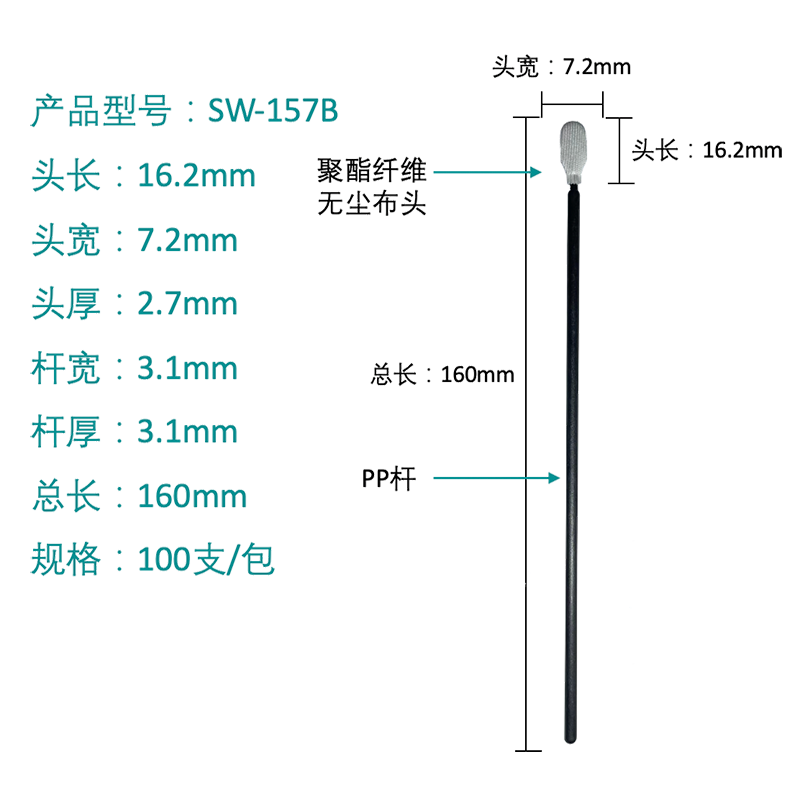

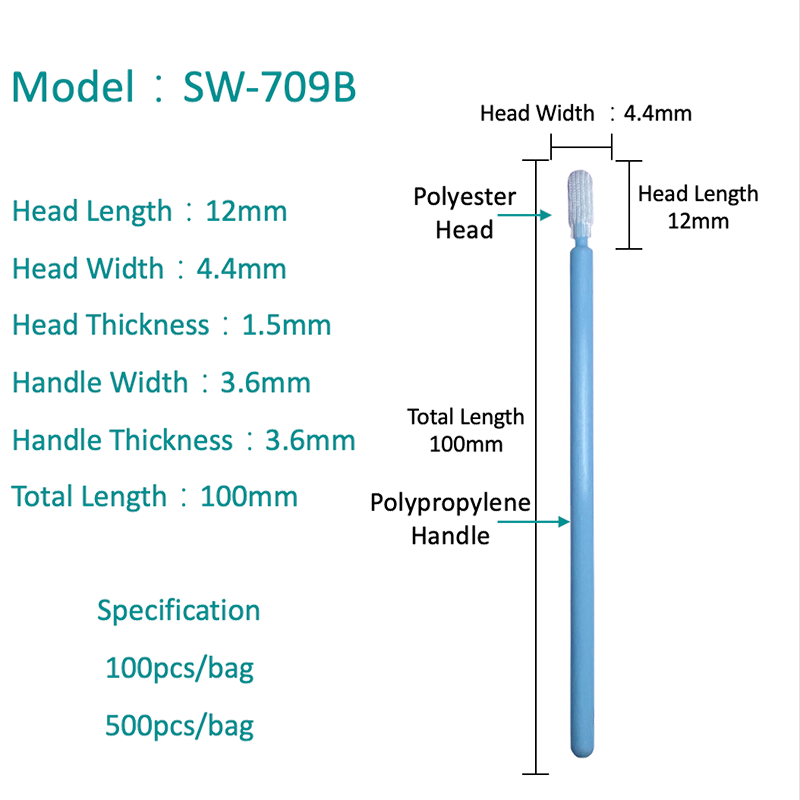

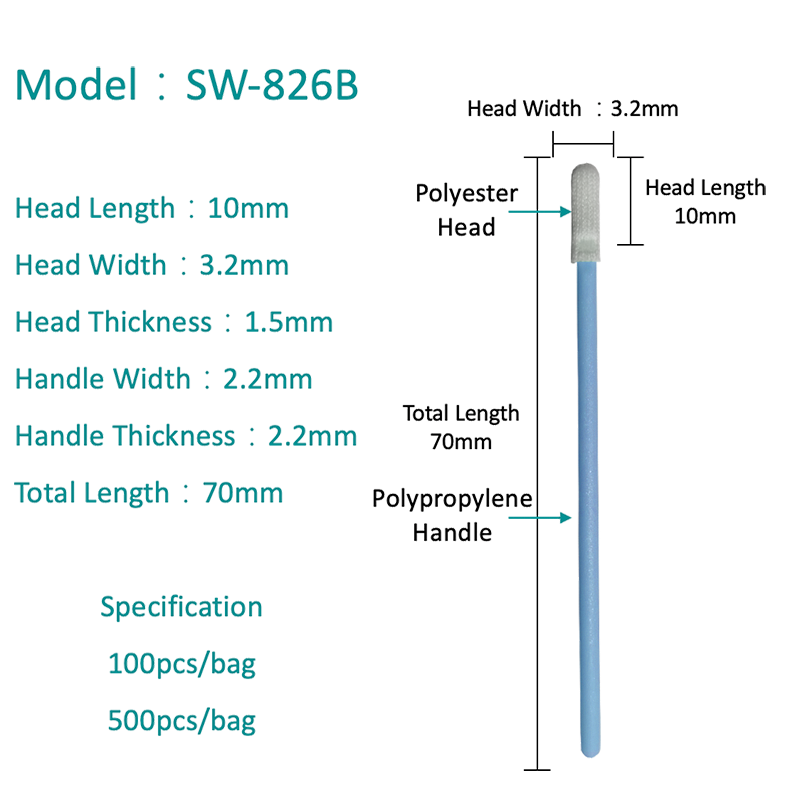

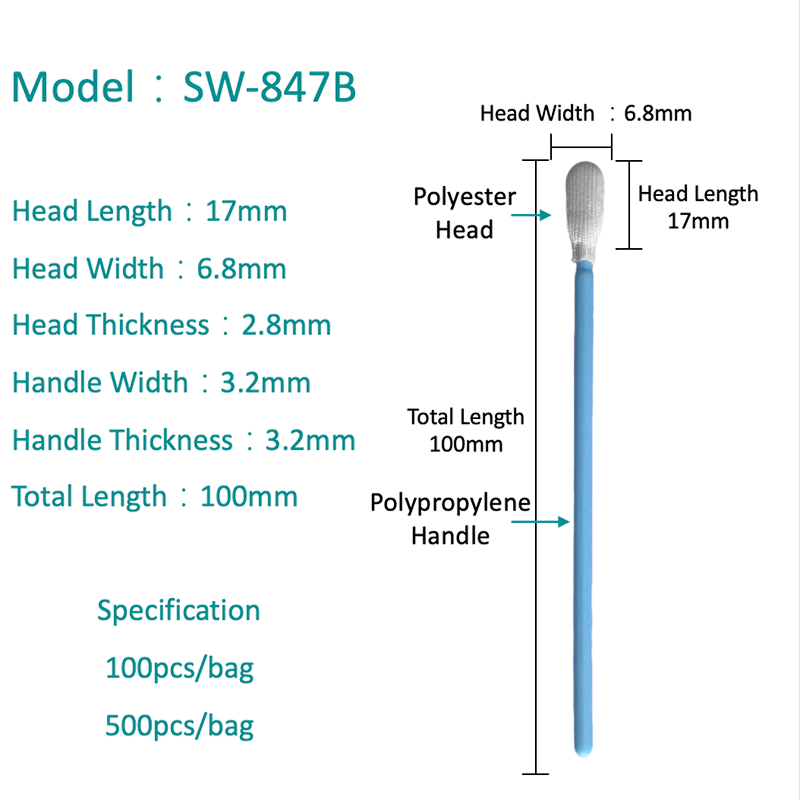

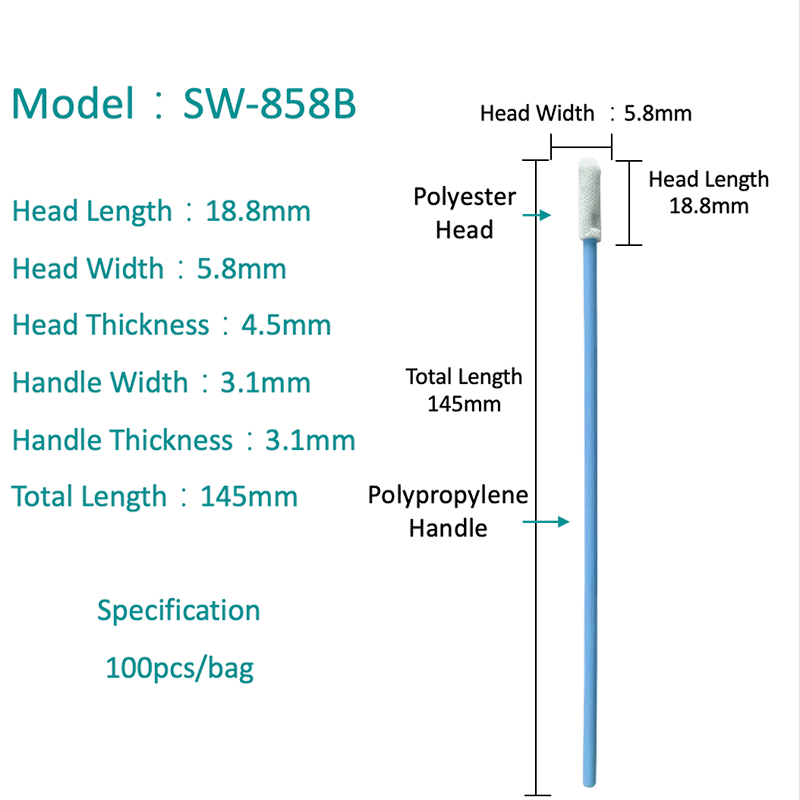

Tip Shape and Fabric Construction

- Pointed Tip: For accessing tight spaces, grooves, and holes.

- Flat/Serpentine Tip: Provides a larger wiping surface for efficient cleaning of flat areas.

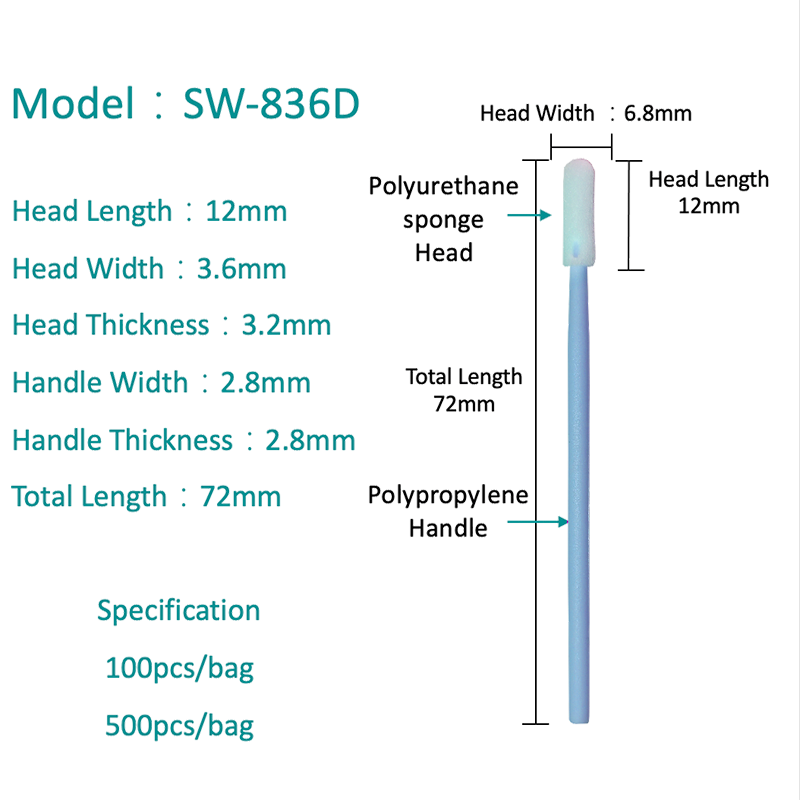

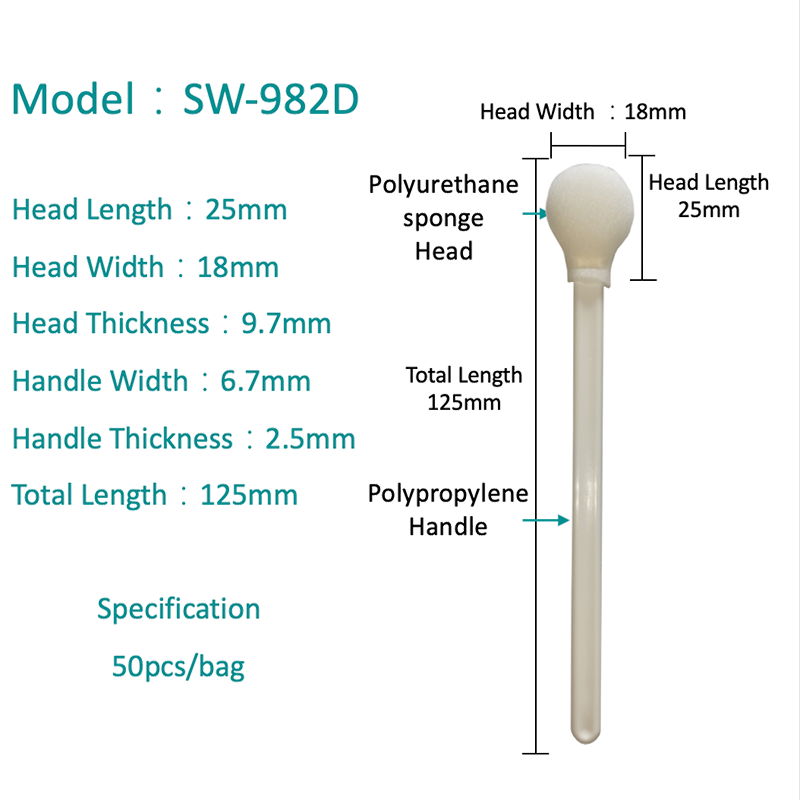

- Bulb/Round Tip: General-purpose shape for applying liquids or gentle wiping.

- Fabric Purity: Bound vs. Knitted. Knitted Dacron fabric, used in high-end swabs, offers superior absorbency and lower particle release compared to bound fibers, making it essential for low-lint dacron swabs for laboratory use [1].

Critical Applications Across Industries

The versatility of Dacron swabs makes them indispensable in fields where precision and cleanliness are non-negotiable.

Electronics and Semiconductor Manufacturing

In this sector, even microscopic particles can cause circuit failure. Dacron swabs are used for:

- Removing flux residue from printed circuit boards (PCBs).

- Precision cleaning of connectors, contacts, and optical components.

- Applying solvents or conformal coatings in controlled amounts.

- Contamination control on wafer handling equipment.

The need for cleaning sensitive electronic components with dacron swabs is paramount, as their low-lint properties prevent new contamination from being introduced during the cleaning process itself.

Medical Device and Pharmaceutical Production

Here, the stakes involve patient safety and product sterility. Applications include:

- Cleaning and disinfecting critical device components before assembly or packaging.

- Applying lubricants or solvents in a controlled manner during manufacturing.

- Surface sampling for bioburden or contamination analysis (using sterile-packaged swabs).

For these tasks, a high-purity dacron swab for medical device cleaning is essential. It must be manufactured in a high-class cleanroom, often gamma-irradiated for sterility, and validated to leave no residues that could interfere with device function or patient health.

Laboratory and Analytical Settings

In labs, swabs are used for both cleaning and sample collection.

- Gently cleaning delicate instrument optics and sensors.

- Wiping down surfaces in sterile hoods or clean benches.

- Collecting surface samples for environmental monitoring (e.g., ATP testing).

The demand for low-lint dacron swabs for laboratory use is high because lint can interfere with sensitive analytical equipment, causing false readings or instrument downtime [2].

Dacron Swabs vs. Alternative Materials: A Detailed Comparison

While Dacron is a top choice, understanding its performance relative to other materials is key to optimal selection.

Dacron vs. Foam Swabs

The debate between dacron vs foam swabs for precision cleaning centers on application. Foam swabs excel at absorbing and holding large volumes of liquid and are ideal for wiping flat, smooth surfaces without scratching. However, Dacron swabs, particularly with knitted fabric, offer superior scrubbing capability for removing adhered particles and are better suited for applications requiring mechanical action or access to threaded areas. Foam may trap and release particles more readily than a tightly knitted Dacron fabric.

| Feature | Dacron Swab | Polyurethane Foam Swab |

| Primary Strength | Scrubbing, particle removal, chemical resistance. | Liquid absorption, gentle wiping on flat surfaces. |

| Lint Generation | Very Low (knitted) | Low to Moderate (can vary by foam quality) |

| Chemical Compatibility | Excellent with a wide range. | Good, but can degrade with strong solvents. |

| Best For | Removing particulate, applying pressure, crevices. | Applying/absorbing liquid, polishing delicate surfaces. |

Dacron vs. Cotton Swabs

This is a clear case of precision versus general purpose. Cotton swabs (like Q-tips®) are inexpensive and ubiquitous but are not suitable for critical environments. They shed a high number of fibers and lint, contain natural impurities and ions, and have lower solvent resistance. For any industrial, electronic, or medical application, dacron swabs are the unequivocally superior choice due to their controlled manufacturing and synthetic purity. The total cost of contamination from a cotton swab far outweighs its lower purchase price.

Best Practices for Using Dacron Swabs Effectively

To maximize performance and maintain cleanliness, follow these guidelines.

Proper Handling and Technique

- Don Gloves: Always handle swabs with clean, powder-free nitrile gloves to prevent skin oils from contaminating the tip.

- Pre-Wetting (if required): For cleaning, gently saturate the swab tip with the appropriate solvent. Avoid over-saturation which can cause drips.

- Apply the Right Pressure: Use firm, controlled pressure for scrubbing, but avoid excessive force that could break the handle or damage the surface.

- Use a Wiping Pattern: Wipe in one direction, rolling the swab to expose a clean surface. Do not go back over an area with a used swab surface.

Storage and Process Integration

Even the best swab is compromised by poor storage. Keep swabs in their original vacuum-sealed packaging until ready for use. In a cleanroom, transfer the required number to a clean container at the workbench. Implement a "one-swab-per-task" rule to prevent cross-contamination. For applications like static dissipative dacron swabs for cleanrooms, ensuring they are used in properly grounded environments is crucial to realize their full ESD-safe benefit [3]. Proper integration into your SOPs ensures consistency and traceability.

Frequently Asked Questions (FAQ)

1. What makes Dacron swabs better than regular cotton swabs for cleanroom use?

Dacron swabs are made from continuous polyester filaments, resulting in extremely low linting and particle generation. They are manufactured in controlled cleanroom environments and cleaned with ultra-pure water, unlike cotton swabs which are naturally fibrous, contain organic impurities, and are produced in non-controlled settings, making them a significant contamination risk.

2. Can Dacron swabs be used with all solvents?

While Dacron has excellent chemical resistance to a wide range of solvents, acids, and alkalis, compatibility should always be verified. Highly aggressive solvents may degrade the polyester fiber or the adhesive bonding the fabric to the handle. Consult the swab manufacturer's chemical compatibility chart for specific solvent recommendations.

3. What does "low-lint" truly mean, and how is it measured?

"Low-lint" is a performance characteristic measured through standardized tests (like IEST-RP-CC004.3) that count the number of particles released by a swab under controlled conditions. A true low-lint dacron swab for laboratory use will have test data showing minimal particles released at specified size thresholds (e.g., ≥0.5µm and ≥5.0µm).

4. When should I choose a static-dissipative Dacron swab?

Choose static dissipative dacron swabs for cleanrooms when working with static-sensitive components like bare semiconductors, magnetic media, or explosive environments. These swabs have a conductive element (often in the handle or coating) that safely drains static charge, preventing Electrostatic Discharge (ESD) damage that a standard swab could cause.

5. How should I dispose of used Dacron swabs?

Disposal must comply with local regulations for chemical and biohazard waste. Swabs used with hazardous chemicals must be disposed of as chemical waste. Those used in biological sampling may be biohazard waste. Always segregate used swabs immediately in appropriately labeled containers at the point of use.

The humble dacron swab is a deceptively sophisticated tool that plays a vital role in maintaining quality and yield across high-tech industries. From cleaning sensitive electronic components with dacron swabs to ensuring the sterility of medical devices, selecting the right swab—with the correct handle, tip, and purity level—is a critical decision. By understanding the material science, manufacturing standards, and best practices outlined in this guide, professionals can leverage these tools to their full potential. Companies like Suzhou Zhuojing Dust-free Technology Co., Ltd. are dedicated to advancing this field through rigorous cleanroom manufacturing, continuous R&D, and a deep commitment to meeting the evolving needs of precision-driven industries with reliable, high-performance consumables.

References

[1] Institute of Environmental Sciences and Technology (IEST). (2004). *IEST-RP-CC004.3: Evaluating Wiping Materials Used in Cleanrooms and Other Controlled Environments*. IEST.

[2] Whyte, W., & Hejab, M. (2007). *Particle and microbial airborne dispersion from people*. Journal of Aerosol Science, 38(5), 485-495.

[3] ESD Association. (2014). *ANSI/ESD S20.20: Standard for the Development of an Electrostatic Discharge Control Program*. ESD Association.

English

English  中文简体

中文简体