HOME / NEWS / Industry News / The Ultimate Guide to Cleaning Swabs: Selection, Applications, and Best Practices

In the world of precision manufacturing, laboratory science, and electronics assembly, the unassuming cleaning swab plays a critical role. Often overlooked, the right swab is fundamental to ensuring product quality, preventing contamination, and maintaining operational integrity. This guide delves deep into the specifications, applications, and selection criteria for industrial-grade cleaning swabs, providing actionable insights for professionals across high-tech sectors.

What Are Industrial Cleaning Swabs?

Industrial cleaning swabs are specialized tools designed for precision cleaning and application tasks in controlled environments. Unlike common cotton swabs, they are engineered to meet stringent standards for particle release, chemical resistance, and absorbency. They are indispensable in sectors where microscopic contamination can lead to significant failures, such as in semiconductor fabrication, aerospace component assembly, and pharmaceutical production.

Suzhou Zhuojing Dust-free Technology Co., Ltd. specializes in the manufacture of these high-precision tools. Operating within Class 10 to Class 1000 cleanrooms and utilizing ultra-pure water (18 mega-ohm) in their cleaning processes, they ensure that every cleaning swab delivered is free from contaminants that could compromise sensitive operations.

Key Factors in Selecting the Right Cleaning Swab

Choosing an incorrect swab can be costly. Selection must be based on a systematic evaluation of the application's requirements against the swab's material properties.

Swab Head Material: A Critical Choice

The head material determines the swab's cleaning effectiveness, compatibility, and potential for leaving residue. Here’s a comparative breakdown:

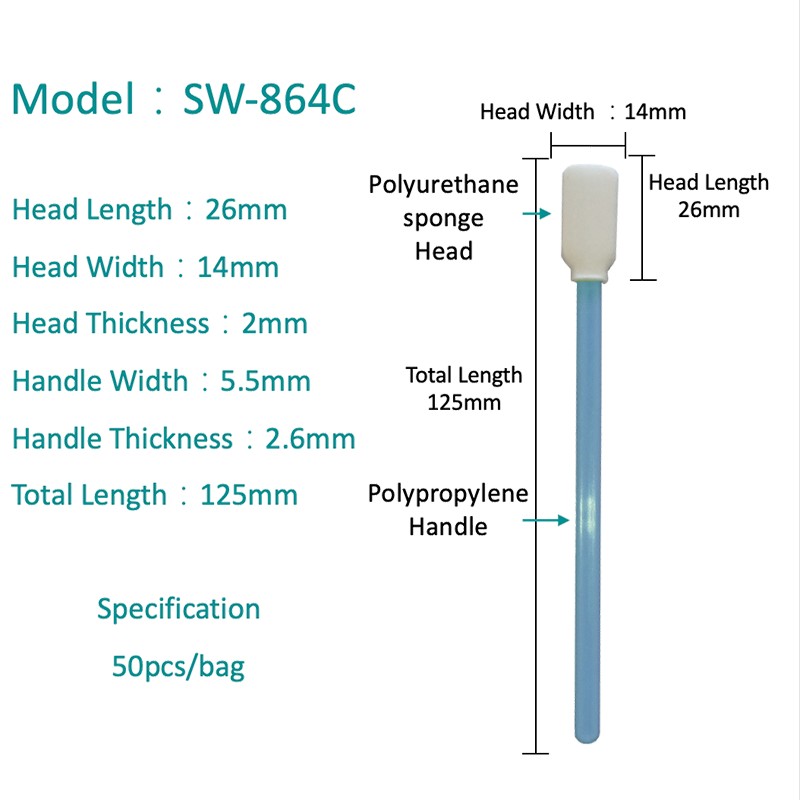

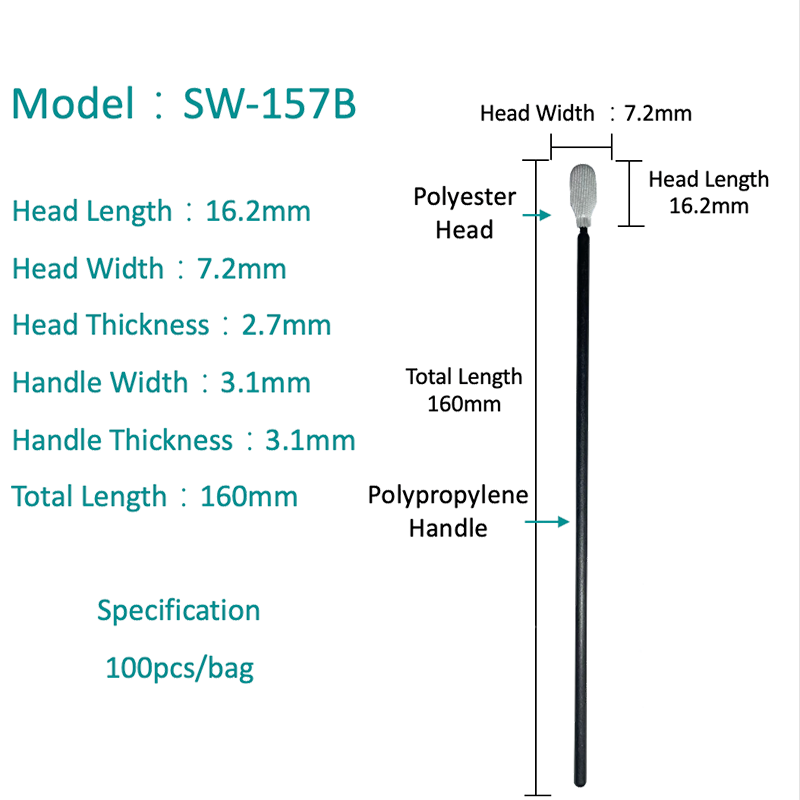

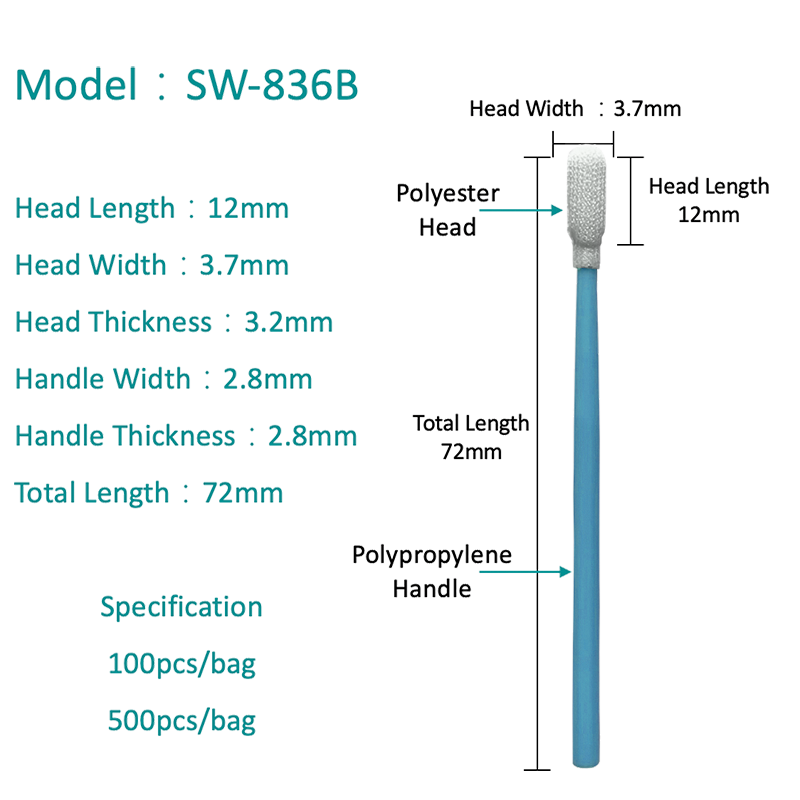

- Polyester (PES): Excellent for general wiping and solvent application. Offers good absorbency and low particulate generation.

- Polyurethane (PU): Superior absorbency and softness. Ideal for delicate surface cleaning where scratching is a concern.

- Cellulose: Highly absorbent for aqueous solutions. Must be checked for linting in critical environments.

- Microfiber: Exceptional for trapping and removing sub-micron particles. Often used for optical and laser cleaning.

The choice of material directly impacts performance. For instance, a polyester swab is more resistant to aggressive solvents than a cellulose one, while a polyurethane foam swab provides better liquid retention for applying lubricants or adhesives in precise locations.

| Material | Best For | Chemical Resistance | Linting Risk |

|---|---|---|---|

| Polyester (PES) | General wiping, solvent use | High | Low |

| Polyurethane (PU) Foam | Delicate surfaces, high absorbency tasks | Moderate to High | Very Low |

| Cellulose | Aqueous cleaning solutions | Low | Medium to High |

| Microfiber | Ultra-fine particle removal, optics | Varies | Low |

Swab Handle and Construction

The handle (shaft) and the method of attaching the head are equally important.

- Handle Materials: PP (polypropylene) is common and cost-effective. For static-sensitive environments, conductive or static-dissipative plastics are mandatory to prevent ESD damage.

- Construction: Swabs can be thermally bonded (head melted onto handle) or adhesively bonded. Thermal bonding is preferred in cleanroom settings as it eliminates the risk of adhesive residue contaminating the head material.

Top 5 Applications and Their Specific Swab Requirements

1. cleaning swab for electronics assembly

In electronics manufacturing, swabs are used to remove flux residue, apply conformal coatings, or clean connectors.

- Key Requirements: Low particulate generation, non-abrasive head, and often ESD-safe handle.

- Material Choice: Polyester or polyurethane foam with a static-dissipative PP handle.

- Benefit: Prevents short circuits and ensures reliable electrical connections.

2. sterile cleaning swabs for medical device manufacturing

Manufacturing implantable devices or diagnostic equipment demands the highest levels of bioburden control.

- Key Requirements: Sterilization (typically Gamma or ETO), validated cleanroom packaging, and ultra-low endotoxin levels.

- Material Choice: Medical-grade PU foam or non-woven polyester, often with a longer handle for aseptic technique.

- Benefit: Mitigates infection risk and meets stringent FDA and ISO 13485 standards.

3. lint free cleaning swabs for optical lenses

Scratches or particles on camera lenses, laser optics, or microscope objectives can severely degrade performance.

- Key Requirements: Absolute minimal linting, extreme softness, and high purity.

- Material Choice: Specially treated microfiber or high-grade, thermally bonded polyester.

- Benefit: Maintains optical clarity without introducing defects.

4. precision cleaning swabs for laboratory use

Labs use swabs for sample collection, instrument maintenance, and precise reagent application.

- Key Requirements: Chemical compatibility with solvents/acids/bases, defined absorbency, and often sterility.

- Material Choice: Chemically inert materials like pure polyester or PTFE-coated options for harsh chemicals.

- Benefit: Ensures accuracy in experiments and prevents cross-contamination.

5. industrial solvent cleaning swabs

Heavy-duty cleaning of machinery, molds, or removing tough adhesives requires swabs that can withstand aggressive chemicals.

- Key Requirements: High solvent resistance, no breakdown or swelling, and good scrubbing ability.

- Material Choice: Solvent-resistant polyester or specialized foam blends designed not to degrade.

- Benefit: Effective cleaning without the tool itself dissolving or leaving residue.

Common Mistakes to Avoid When Using Cleaning Swabs

Even the best swab can cause issues if used incorrectly. Awareness of these pitfalls is crucial.

- Over-Saturation: Drenching the swab head causes dripping, which can spread contamination or damage components. The swab should be damp, not wet.

- Reusing Swabs: A single swab should be used for a single pass or task. Reusing a swab redeposits contaminants.

- Using the Wrong Solvent: An incompatible solvent can degrade the swab material, leaving behind particles or gel-like residues.

- Ignoring ESD Precautions: Using a standard swab on a static-sensitive assembly can cause latent ESD damage, leading to field failures.

Why Cleanroom Manufacturing Matters for Cleaning Swabs

The environment where a cleaning swab is produced is as important as its design. Swabs manufactured in non-controlled environments can be a source of contamination themselves [1].

Suzhou Zhuojing Dust-free Technology Co., Ltd. addresses this fundamental concern head-on. Their entire production process, from molding to packaging, takes place in certified cleanrooms (Class 10 to Class 1000). The final cleaning with 18 mega-ohm ultra-pure water removes ionic and particulate contaminants to levels suitable for the most sensitive applications. Subsequent vacuum sealing ensures the swab's cleanliness is preserved until the moment it is opened by the end-user. This vertically controlled, high-standard manufacturing is what differentiates industrial-grade swabs from their commercial counterparts.

Frequently Asked Questions (FAQs)

1. What is the difference between a sterile swab and a cleanroom swab?

A sterile cleaning swab has undergone a validated process (like Gamma irradiation) to eliminate viable microorganisms. A cleanroom swab is manufactured and packaged in a controlled environment to minimize particulate and non-viable contamination. A swab can be both sterile and cleanroom-grade, which is essential for medical device and pharmaceutical applications.

2. How do I choose between foam and non-woven fabric for a swab head?

Choose foam (like PU) for superior absorbency and soft contact with delicate surfaces. Choose non-woven fabric (like polyester) for greater abrasion resistance, better solvent compatibility, and typically lower particle release. The choice for a cleaning swab for electronics assembly often leans towards foam for flux removal and non-woven for scrubbing.

3. Why are ESD-safe swabs necessary?

Electrostatic discharge (ESD) can instantly damage microchips and electronic components. ESD-safe swabs have conductive or static-dissipative handles that safely ground any static charge through the user, preventing a damaging spark. This is a non-negotiable feature for handling printed circuit boards (PCBs).

4. Can I autoclave my cleaning swabs for reuse?

It is strongly discouraged. Most swab materials (plastics, foams, adhesives) are not designed to withstand repeated autoclaving cycles, which can degrade them and increase particle shedding. For critical applications, always use a new, pre-cleaned or sterile swab. This is a key principle when selecting precision cleaning swabs for laboratory use.

5. What does "low linting" actually mean?

Low linting refers to a swab's propensity to release fibers or particles during use. It is quantified through standardized tests (like IEST-RP-CC004) that measure the number of particles released per swipe. Lint free cleaning swabs for optical lenses would have an exceptionally low score on these tests, often verified by the manufacturer's quality control.

Selecting the right cleaning swab is a precise science that directly impacts yield, quality, and reliability in high-tech industries. By understanding the core variables—material compatibility, cleanroom pedigree, and application-specific needs—professionals can make informed decisions that safeguard their processes. From industrial solvent cleaning swabs to sterile medical variants, the principle remains: the tool must be as clean and controlled as the environment in which it is used. Partners like Suzhou Zhuojing Dust-free Technology Co., Ltd., with their dedicated cleanroom manufacturing and focus on OEM/ODM collaboration, provide the foundational quality assurance that allows industries to push the boundaries of precision and cleanliness.

References

[1] IEST. (n.d.). *IEST-RP-CC004: Evaluating Wiping Materials Used in Cleanrooms and Other Controlled Environments*. Institute of Environmental Sciences and Technology. This standard outlines methods for assessing the particle release and cleanliness of wipers and swabs, highlighting the importance of controlled manufacturing.

English

English  中文简体

中文简体