HOME / NEWS / Industry News / The Ultimate Guide to 707 Clean Swab for Printer Foam Maintenance

Understanding the 707 Clean Swab and Its Role in Printer Care

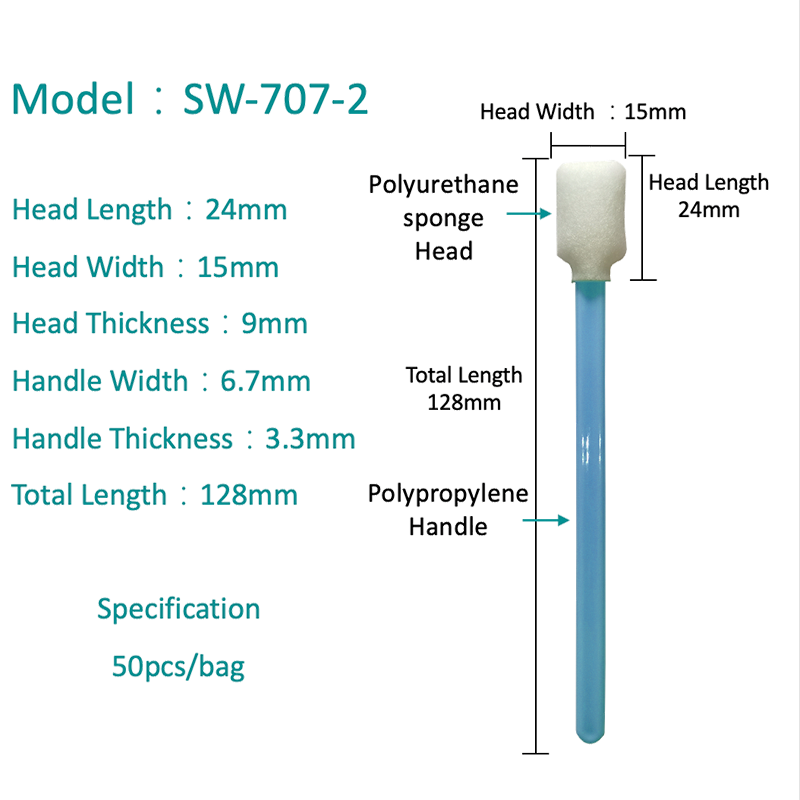

In the realm of printer maintenance, precision cleaning is not just a recommendation; it is a necessity for ensuring optimal performance and longevity of your equipment. Among the various tools designed for this purpose, the 707 clean swab for printer foam stands out as a specialized instrument. This swab is specifically engineered to address the unique cleaning requirements of printer components, particularly those involving delicate foam parts that are integral to the ink distribution system. The number 707 typically refers to the size and shape of the swab, which is optimized for accessing tight spaces and applying cleaning solutions without leaving lint or residues behind. Understanding the construction and proper use of this tool is the first step toward effective printer maintenance.

What Makes the 707 Swab Unique?

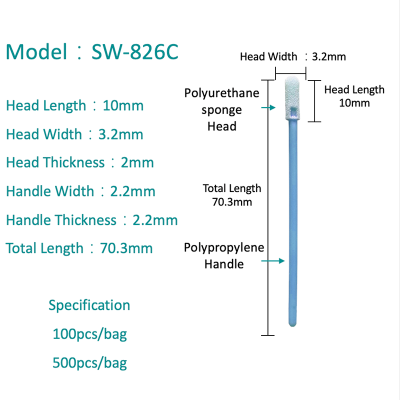

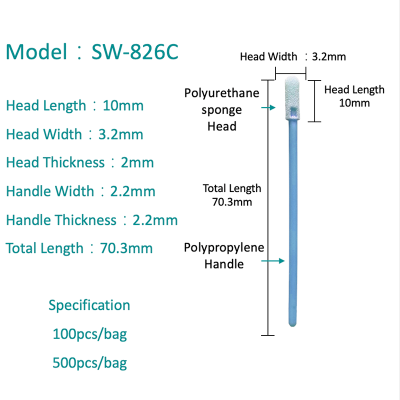

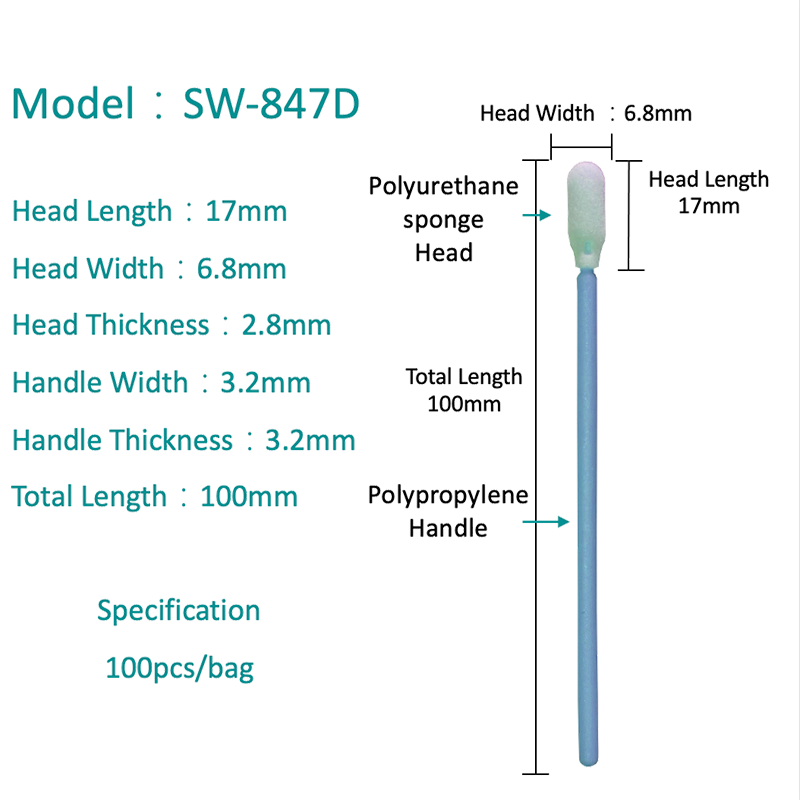

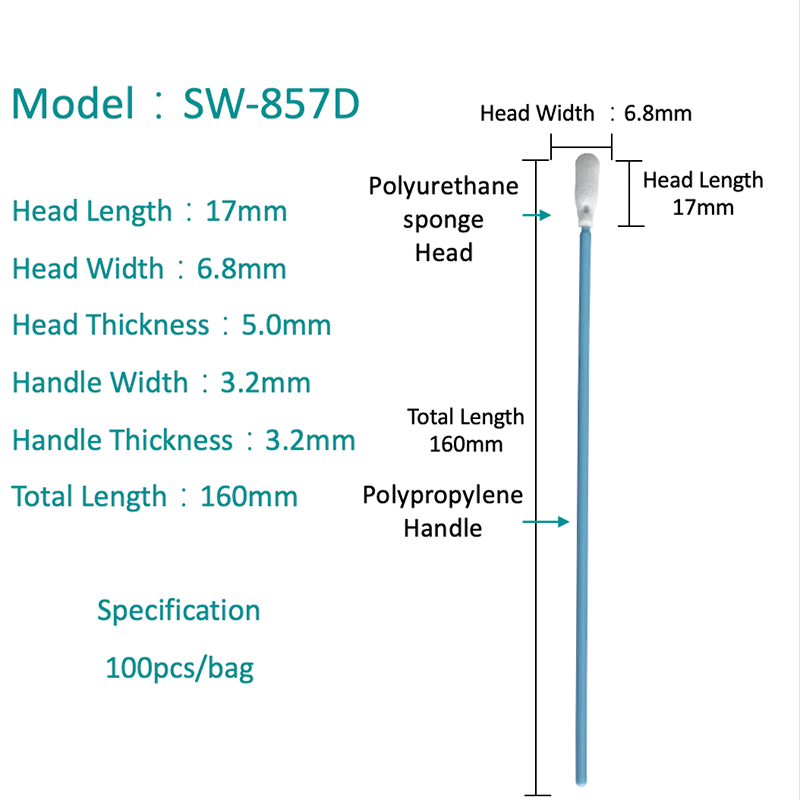

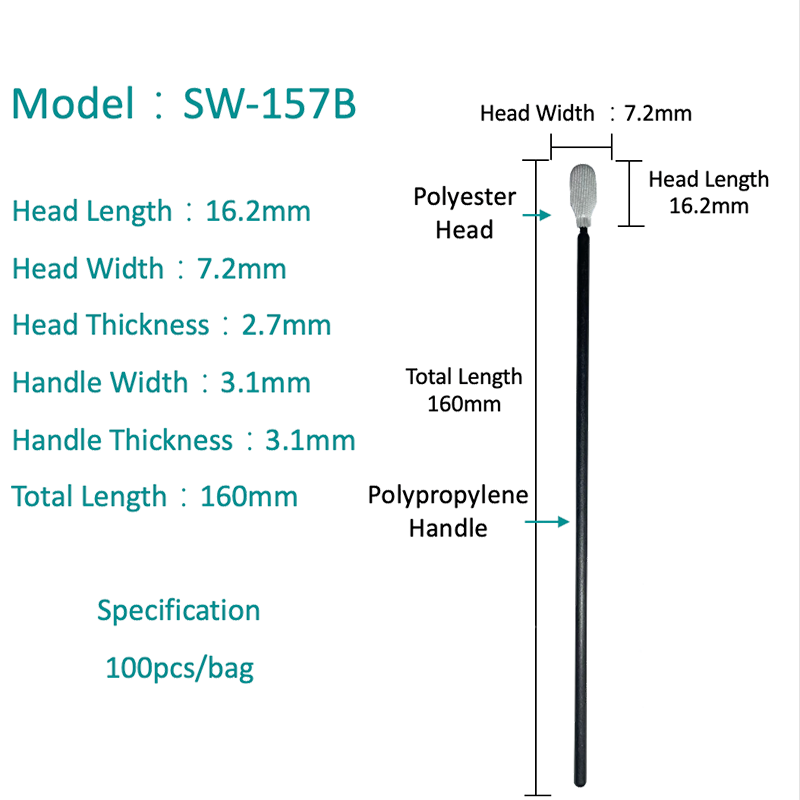

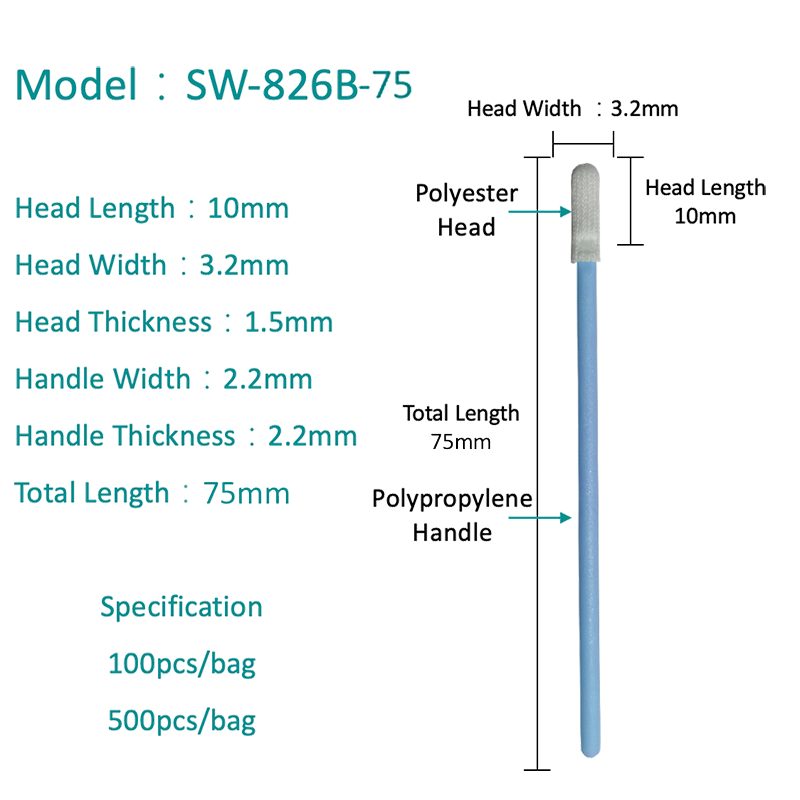

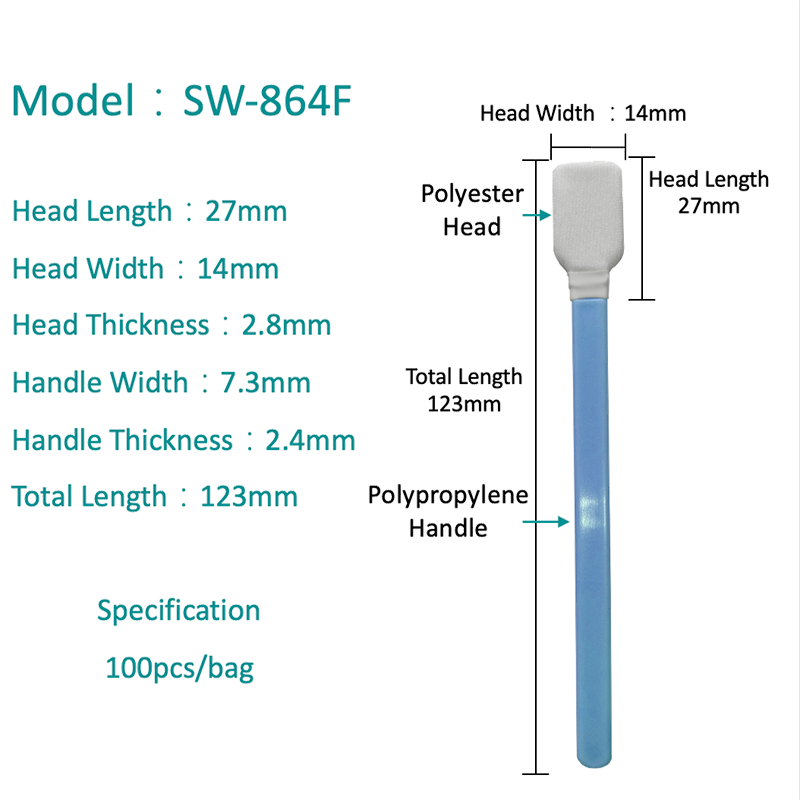

The 707 clean swab is distinct from generic cleaning tools due to its design and material composition. The swab features a foam tip that is highly absorbent and soft, ensuring that it does not scratch or damage sensitive printer parts. The handle is often made of plastic or another rigid material that provides control during cleaning. This combination allows for the precise application of solvents and the gentle removal of ink buildup, dust, and debris. Unlike cotton swabs, which can shed fibers and cause blockages, the 707 swab is designed to be lint-free, making it a safer choice for internal printer components. The importance of using the right tool cannot be overstated, as improper cleaning can lead to print quality issues, such as streaking, smudging, or even permanent damage to print heads.

The Critical Role of Foam Components in Printers

Printers, especially inkjet models, contain various foam parts that play crucial roles in the printing process. These include ink absorbers, wipers, and pads that manage excess ink, clean the print head, and prevent leaks. Over time, these foam components can become saturated with ink and debris, reducing their effectiveness and potentially causing ink to overflow or contaminate other parts of the printer. Regular cleaning with a 707 clean swab for printer foam helps maintain these components, ensuring they function correctly and extend the life of the printer. Neglecting this maintenance can result in costly repairs or the need for premature replacement of parts. Therefore, incorporating the use of the 707 swab into your routine printer care is a proactive measure that pays off in the long run.

How to Effectively Use a 707 Clean Swab for Printer Maintenance

Using a 707 clean swab correctly is essential to achieving the desired cleaning outcomes without causing harm to your printer. This process involves several steps, from preparing the printer and selecting the appropriate cleaning solution to executing the cleaning with precision. First, always ensure that the printer is turned off and unplugged to avoid any electrical hazards or accidental movement during cleaning. Next, open the printer covers to access the internal components, referring to the manufacturer’s manual for guidance on locating foam parts like ink absorbers and wipers. It is crucial to use a cleaning solution that is compatible with your printer; isopropyl alcohol is commonly recommended for its effectiveness in dissolving ink and quick evaporation.

Step-by-Step Cleaning Procedure

To clean printer foam components, lightly dampen the foam tip of the 707 swab with the cleaning solution. Avoid oversaturating the swab, as excess liquid can drip into other parts of the printer and cause damage. Gently wipe the foam component, such as an ink absorber or wiper, using a circular or back-and-forth motion to loosen and absorb ink buildup. For stubborn deposits, you may need to repeat the process with a fresh swab. After cleaning, allow the components to air dry completely before closing the printer and powering it on. This ensures that no moisture remains that could interfere with printer operation. Regularly performing this maintenance, such as monthly or after every few ink cartridge changes, can prevent common issues and maintain print quality.

Common Mistakes to Avoid

While using a 707 clean swab is relatively straightforward, there are pitfalls that users should be aware of. One common mistake is using too much force during cleaning, which can dislodge or damage delicate foam parts. Another error is using inappropriate cleaning solutions, such as those containing oils or additives, which can leave residues that attract more dirt or interfere with ink flow. Additionally, neglecting to dry components thoroughly can lead to electrical shorts or ink smearing. By avoiding these mistakes and following best practices, you can maximize the benefits of using a 707 clean swab for printer foam and keep your printer in top condition.

Top Benefits of Regular Printer Foam Cleaning with 707 Swabs

Regular maintenance of printer foam components using 707 clean swabs offers numerous advantages that contribute to the overall efficiency and cost-effectiveness of your printing operations. One of the primary benefits is the improvement in print quality. Clean foam parts ensure that ink is properly managed, reducing the risk of streaks, blots, or faded prints. This is particularly important for professionals who rely on high-quality outputs, such as photographers or graphic designers. Additionally, consistent cleaning extends the lifespan of both the foam components and the printer itself, delaying the need for replacements and reducing long-term costs.

Enhancing Printer Reliability and Performance

Printers that undergo regular maintenance are less likely to experience unexpected failures or jams. By using a 707 clean swab for printer foam, you can prevent ink clogs and ensure that moving parts operate smoothly. This reliability is crucial in environments where printers are used frequently, such as offices or print shops, as downtime can disrupt workflow and productivity. Moreover, well-maintained printers operate more efficiently, often consuming less ink and energy due to reduced strain on the system. This not only saves money but also supports environmental sustainability by minimizing waste.

Cost Savings and Environmental Impact

Investing in routine cleaning with 707 swabs is a cost-effective strategy compared to dealing with major repairs or replacements. For instance, replacing a print head can be expensive, whereas regular cleaning can prevent the need for such interventions. Additionally, by maintaining your printer properly, you contribute to reducing electronic waste, as printers are kept in service longer. This aligns with growing trends toward sustainability and responsible resource management. Thus, the humble 707 swab becomes a tool not just for printer care, but for broader economic and environmental benefits.

Comparing 707 Clean Swabs with Alternative Cleaning Methods

When it comes to cleaning printer foam components, several methods and tools are available, each with its own set of advantages and limitations. Understanding how 707 clean swab for printer foam compares to these alternatives can help users make informed decisions about their maintenance routines. Common alternatives include cotton swabs, compressed air, and pre-moistened wipes. While each has its place, the 707 swab often emerges as the superior choice for specific applications due to its design and material properties.

707 Swabs vs. Cotton Swabs

Cotton swabs are widely available and inexpensive, but they are not ideal for printer cleaning. The primary issue is lint shedding; cotton fibers can detach during use and clog printer nozzles or mechanisms. In contrast, 707 swabs are designed to be lint-free, making them safer for internal components. Additionally, the foam tip of a 707 swab is more absorbent and provides better control for applying cleaning solutions precisely. For example, when cleaning a printer's ink absorber, a cotton swab might leave behind fibers that could mix with ink and cause blockages, whereas a 707 swab effectively removes debris without residue. This makes the 707 clean swab for printer foam a more reliable option for maintaining print quality and preventing damage.

707 Swabs vs. Compressed Air and Pre-Moistened Wipes

Compressed air is useful for blowing dust out of hard-to-reach areas, but it is ineffective for cleaning ink-saturated foam components, as it cannot dissolve or absorb ink. Moreover, compressed air can force debris deeper into the printer, potentially causing more harm than good. Pre-moistened wipes offer convenience but often lack the precision needed for small components; they may also contain chemicals that are not suitable for all printer parts. The 707 swab, with its targeted application and compatibility with various cleaning solutions, provides a balanced approach that addresses these limitations. Below is a comparison table highlighting key differences:

| Method | Pros | Cons | Best Use Case |

|---|---|---|---|

| 707 Clean Swab | Lint-free, precise, absorbent, safe for delicate parts | May require purchasing specialized tool | Cleaning ink absorbers, wipers, and other foam components |

| Cotton Swab | Inexpensive, readily available | Lint shedding, less absorbent | External cleaning only |

| Compressed Air | Good for dust removal, reaches tight spaces | Can push debris inward, not effective for ink | Removing loose dust from non-sensitive areas |

| Pre-Moistened Wipes | Convenient, no additional solution needed | May contain harsh chemicals, less precise | Cleaning exterior surfaces |

This comparison underscores why the 707 swab is the preferred choice for internal foam components, offering a combination of safety, effectiveness, and precision that alternatives lack.

Finding the Best 707 Clean Swab for Your Printer Needs

Selecting the right 707 clean swab for printer foam involves considering factors such as material quality, compatibility with cleaning solutions, and value for money. Not all swabs are created equal, and choosing a subpar product can lead to inadequate cleaning or even damage. High-quality 707 swabs typically feature dense, lint-free foam tips that are firmly attached to sturdy handles. They should be resistant to common cleaning solvents like isopropyl alcohol without breaking down or leaving residues. When purchasing, look for products that are specifically labeled for printer or electronic maintenance, as these are more likely to meet the necessary standards.

Where to Source Reliable 707 Clean Swabs

While we avoid mentioning specific brands or shopping sites, it is important to seek out suppliers that specialize in printer maintenance supplies. These suppliers often provide detailed product descriptions and specifications, allowing you to verify that the swabs are suitable for your printer model. Reading customer reviews can also offer insights into the product's performance and reliability. Additionally, consider purchasing in bulk if you perform regular maintenance, as this can be more economical. Remember, investing in quality tools like the 707 clean swab for printer foam is a small cost compared to the potential expenses of printer repairs or replacements.

Ensuring Compatibility and Effectiveness

Before using a new batch of 707 swabs, test one on a less critical area if possible, to ensure it does not shed or react adversely with your cleaning solution. Also, follow the printer manufacturer’s guidelines for cleaning intervals and techniques to maximize effectiveness. By taking these steps, you can be confident that you are using the best tool for the job, ultimately protecting your printer and enhancing its performance. The right 707 clean swab for printer foam will become an indispensable part of your maintenance toolkit, contributing to consistent print quality and printer longevity.

Troubleshooting Common Printer Issues with 707 Clean Swabs

Even with regular maintenance, printers can occasionally experience problems. Many of these issues, however, can be resolved or prevented through targeted cleaning with a 707 clean swab for printer foam. Common problems include ink smearing, poor print quality, and error messages related to ink absorption. Understanding how to diagnose and address these issues with the help of a 707 swab can save time and money, avoiding unnecessary service calls or part replacements.

Addressing Ink Smearing and Streaking

Ink smearing or streaking often indicates that the printer’s wiper blades or ink absorbers are saturated with ink or debris. These components are responsible for cleaning the print head and managing excess ink during printing. To address this, use a 707 swab dampened with cleaning solution to gently clean the wiper blades and absorbers. This removes the buildup that causes smearing and restores proper function. If the problem persists after cleaning, it may be a sign that the components need replacement, but in many cases, thorough cleaning with a 707 swab is sufficient to resolve the issue.

Solving Error Messages and Ink Flow Problems

Printers may display error messages related to ink overflow or absorption failures. These messages often point to clogged or full foam components that can no longer absorb ink effectively. Using a 707 swab to clean these parts can alleviate the problem by restoring their absorbency. Additionally, if you notice inconsistent ink flow or faded prints, it could be due to blockages in the foam parts that regulate ink distribution. Carefully cleaning these areas with a 707 swab can improve ink flow and print quality. By incorporating the 707 clean swab for printer foam into your troubleshooting routine, you can effectively address these common issues and keep your printer running smoothly.

Long-Term Maintenance Strategies for Printer Foam Components

Beyond immediate cleaning, adopting long-term maintenance strategies is essential for maximizing the life and performance of your printer’s foam components. This involves regular inspections, scheduled cleanings, and understanding when to replace parts. The 707 clean swab for printer foam plays a key role in this proactive approach, allowing you to maintain components before problems arise. Set a maintenance schedule based on your printer usage; for high-volume printing, clean foam parts monthly, while for light use, quarterly may suffice.

When to Replace Foam Components

Despite regular cleaning, foam components will eventually wear out and lose their absorbency. Signs that replacement is needed include persistent error messages, ink leaks, or visible deterioration of the foam. When replacing these parts, use the opportunity to thoroughly clean the surrounding areas with a 707 swab to prevent new components from becoming contaminated quickly. Keeping spare foam parts on hand can minimize downtime when replacements are necessary. By combining regular cleaning with timely replacements, you ensure that your printer remains reliable and efficient for years to come.

Integrating 707 Swabs into a Comprehensive Maintenance Plan

A comprehensive maintenance plan should include not only cleaning but also other practices such as using high-quality ink, storing printers properly, and keeping firmware updated. The 707 clean swab for printer foam is a cornerstone of this plan, addressing one of the most critical aspects of printer care. Document your maintenance activities to track the condition of components over time and identify patterns that may indicate underlying issues. This holistic approach not only enhances printer performance but also extends its lifespan, providing excellent return on investment through reduced costs and improved reliability.

English

English  中文简体

中文简体