HOME / NEWS / Industry News / Why Foam Tips Are the New Gold Standard in Swabs

What Makes a Foam Tip Swab Different

Material and Structure

The cornerstone of a foam tip swab lies in its innovative design: instead of traditional cotton, the tip is made from a dense, yet soft, open‑cell foam. This foam is engineered to be both absorbent and resilient — it can hold cleaning fluid or alcohol, yet remain firm enough to transfer or remove dirt, debris, or residue without flaking or leaving fibers behind. The result is a swab whose performance is consistent, reliable, and tailored for delicate or precision tasks. Because foam doesn’t shed fibers like cotton, it's particularly suited for sensitive surfaces, electronics, and sterile environments.

- Open‑cell foam tip absorbs and releases fluid evenly — ideal for cleaning or sample collection.

- Non‑shedding — avoids residue or lint, especially important for electronics or optical surfaces.

- Consistent shape and density — ensures repeatable results across uses.

- Often compatible with sterilization processes — useful for medical or lab applications.

Advantages over Traditional Cotton Swabs

When evaluating foam tip swab vs cotton swab cleaning effectiveness, the differences become clear. Traditional cotton swabs may leave behind fibers, struggle with narrow or irregular surfaces, or compress under pressure — reducing cleaning efficiency. In contrast, foam‑tip swabs maintain their structure, offer better fluid control, and reach into small crevices more effectively. For many users, this means fewer passes, less risk of damage, and a cleaner result. These advantages explain why foam swabs have emerged as a preferred choice across various professional and consumer tasks.

- Better fluid control — foam soaks and releases liquids in a controlled manner.

- Improved access — foam tip can enter narrow spaces without collapsing.

- Less risk of residue — foam doesn’t leave cotton lint behind.

- More durable tip — foam resists shredding or deformation under pressure.

| Cotton Swab | Foam Tip Swab | |

| Fluid Absorption & Release | Variable, can drip or over‑absorb | Consistent and controlled |

| Fiber Shedding | Often sheds fibers | Minimal to none |

| Access to Tight Spaces | Tip may compress or bend | Tip remains firm and precise |

| Suitability for Sensitive Surfaces | Higher risk of lint/residue | Low risk — ideal for electronics, optics, medical use |

Key Use Cases for Foam Tip Swabs

Electronics Cleaning

For delicate electronics — from circuit boards to ports and connectors — precision and cleanliness are critical. A foam tip swab for electronics cleaning offers a gentle yet effective way to remove dust, grime, and flux residues without scratching or leaving fibers. Because the foam holds cleaning solvent and releases it evenly, it can clean sensitive contacts or optical sensors without over‑wetting. For technicians or DIYers working on laptops, game consoles, cameras, or other intricate devices, foam tip swabs reduce the risk of short‑circuits, residue buildup, or accidental damage.

- Safely cleans ports, connectors, circuit boards, and sensor lenses.

- Applies isopropyl alcohol or cleaning solution with precision.

- Reaches tight nooks and irregular surfaces without damaging components.

- Minimizes lint or residue that could interfere with electrical contacts.

Earbud and Small Device Maintenance

Many earbuds, hearing‑aids, or tiny handheld devices accumulate earwax, dirt, or sweat residue over time. A foam tip swab for earbud maintenance is often the most effective tool to keep these devices hygienic and functioning. The foam tip’s soft texture ensures no scratching of metal or plastic surfaces, while its controlled absorption picks up residue without soaking surrounding areas. This makes foam tip swabs a favorite for cleaning charging contacts, speaker grills, or charging ports where precision and cleanliness matter.

- Gently removes earwax, debris, or dust without damaging device surfaces.

- Reaches tight grooves in speaker grills or mesh filters.

- Applies cleaning fluid sparingly to avoid moisture damage.

- Prevents lint or fiber deposition that can affect sound quality or charging contacts.

Dust Removal in Tight Spaces

Performing a thorough clean in hard‑to‑reach areas — like keyboard gaps, ventilation slots, or precision instruments — calls for a tool that can navigate narrow crevices while capturing dust efficiently. A disposable foam tip swab for dust removal in tight areas excels at this: its firm yet pliable tip slips into confined spaces and picks up particulate matter without scattering it or leaving residues behind. For maintenance tasks requiring precision (e.g. cleaning mechanical keyboards, camera mounts, switches), foam swabs outperform cotton alternatives due to their shape retention and controlled material pickup.

- Accesses narrow slots, vents, or grooves that are difficult with cloth or brush.

- Captures dust and particles efficiently without dispersing them.

- Disposable — ideal for one‑time cleaning to avoid cross‑contamination.

- Useful for maintenance of mechanical gear, instruments, or equipment with tight tolerances.

Medical & Laboratory Sample Collection

In medical or lab settings, sterility, accuracy, and contamination prevention are vital. A sterile foam tip swab for medical sample collection delivers on these demands: the foam tip can absorb biological samples ( fluids, secretions ) uniformly, while its smooth surface minimizes sample loss or fragmentation. Additionally, sterilized foam swabs are less likely to shed particles that could contaminate a sample — which is critical for diagnostic accuracy. Whether collecting nasal, wound, or surface samples, foam tip swabs provide a hygienic, reliable solution for sensitive biological applications.

- Offers uniform absorption of fluids or secretions — important for consistent sampling.

- Minimal shedding — reduces risk of contamination in lab assays or diagnostics.

- Often pre‑sterilized or sterilization‑compatible for medical uses.

- Gentle yet effective — suitable for swabbing small wounds, collection surfaces, or sensitive areas.

How to Choose the Right Foam Tip Swab

Sterility — When You Need Sterile Foam Tip Swab

If you plan to use swabs for medical sampling, wound care, or any application where contamination could affect results or safety, selecting a sterile foam tip swab is essential. Sterilization ensures that the swab itself doesn’t introduce bacteria, dust, or foreign particles that may skew diagnostic outcomes or compromise cleanliness. For lab-grade work or medical contexts, sterile packaging and individually wrapped swabs offer the peace of mind necessary to maintain hygiene and accuracy.

- Choose individually packaged, sterilized swabs when working with biological samples.

- Check for sterile‑grade certification or labeling when purchasing swabs for medical/lab use.

- Store unopened swabs in clean, dry conditions until use.

- Use once and discard to avoid cross‑contamination.

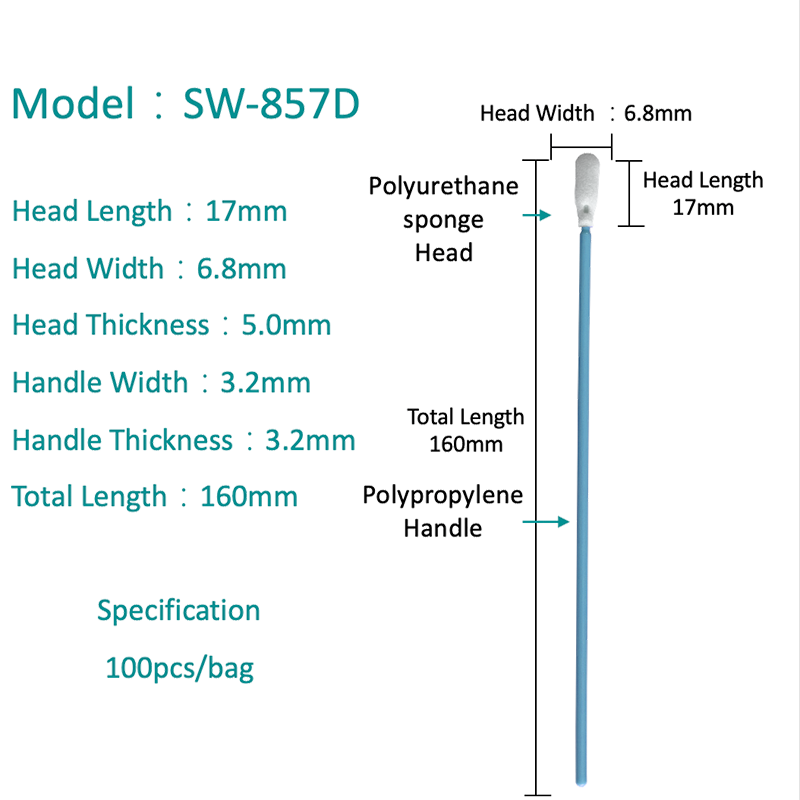

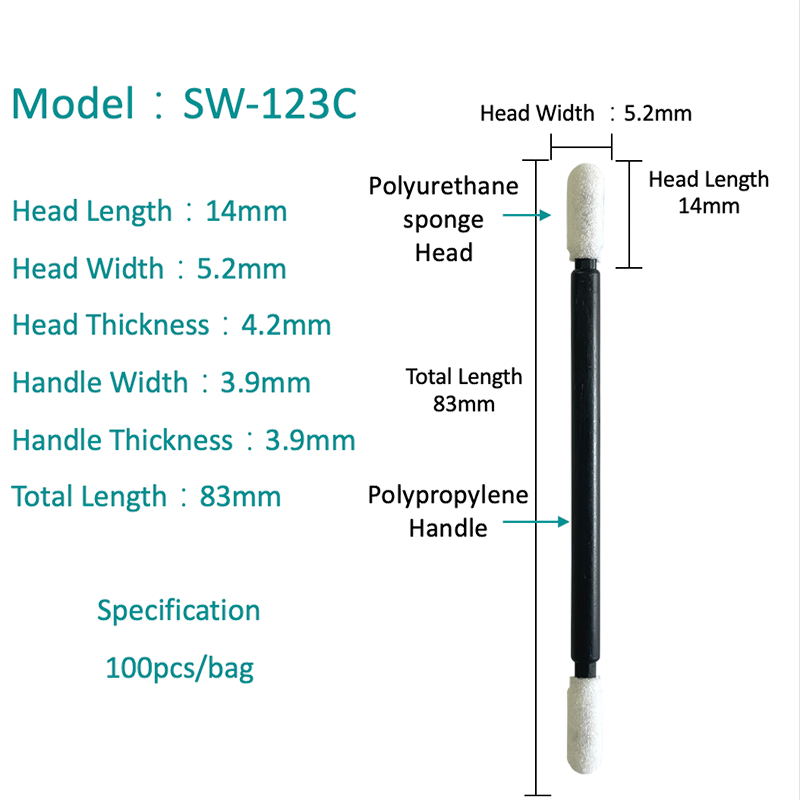

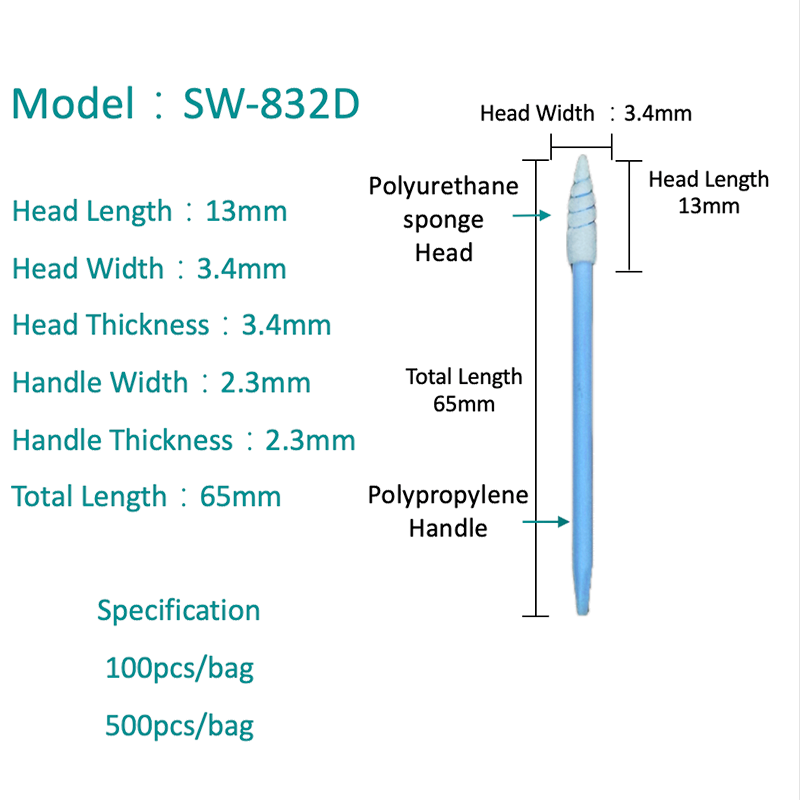

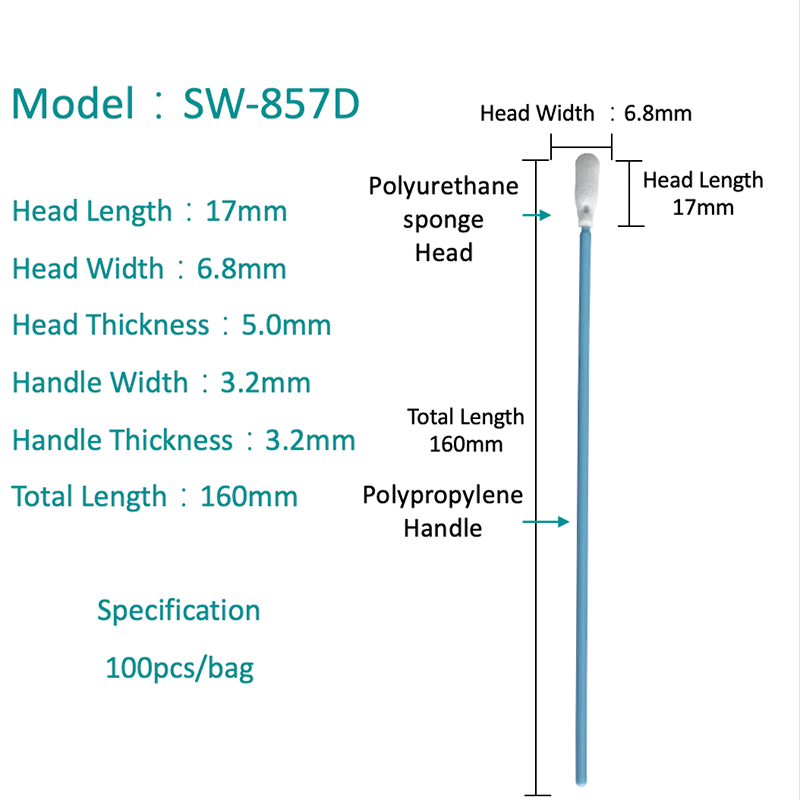

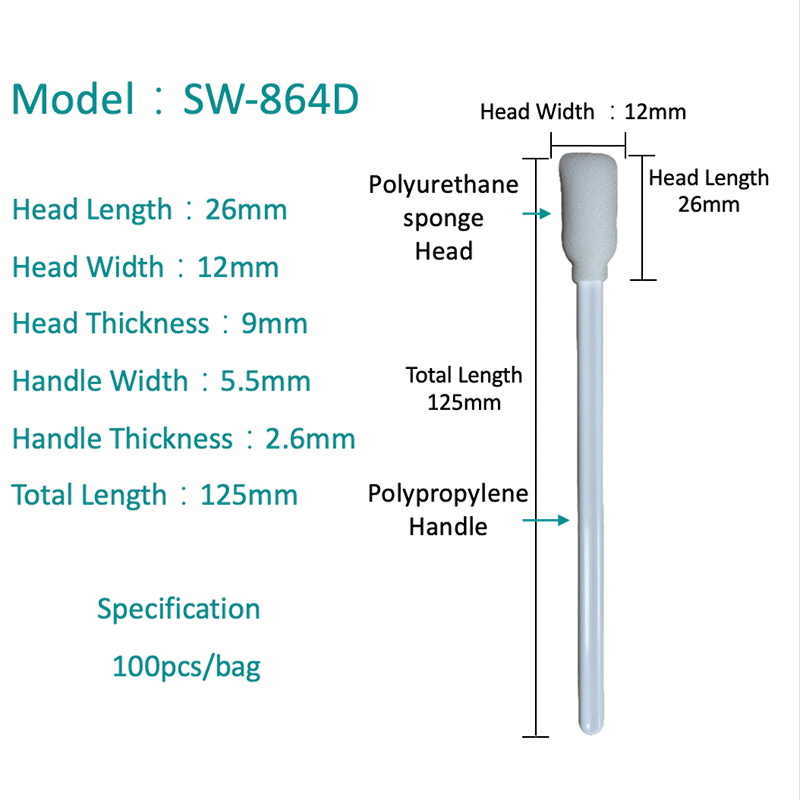

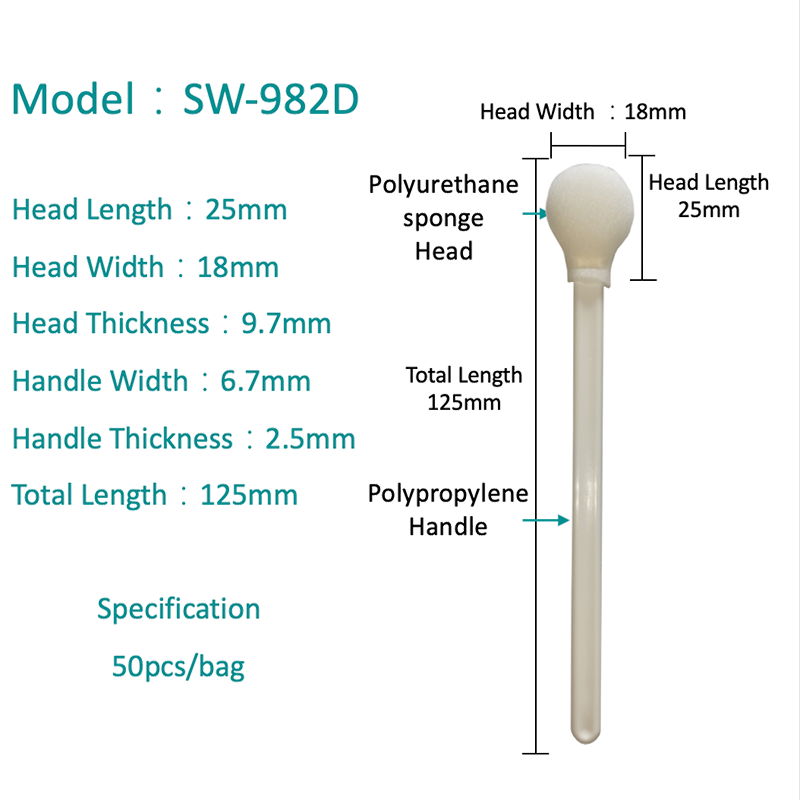

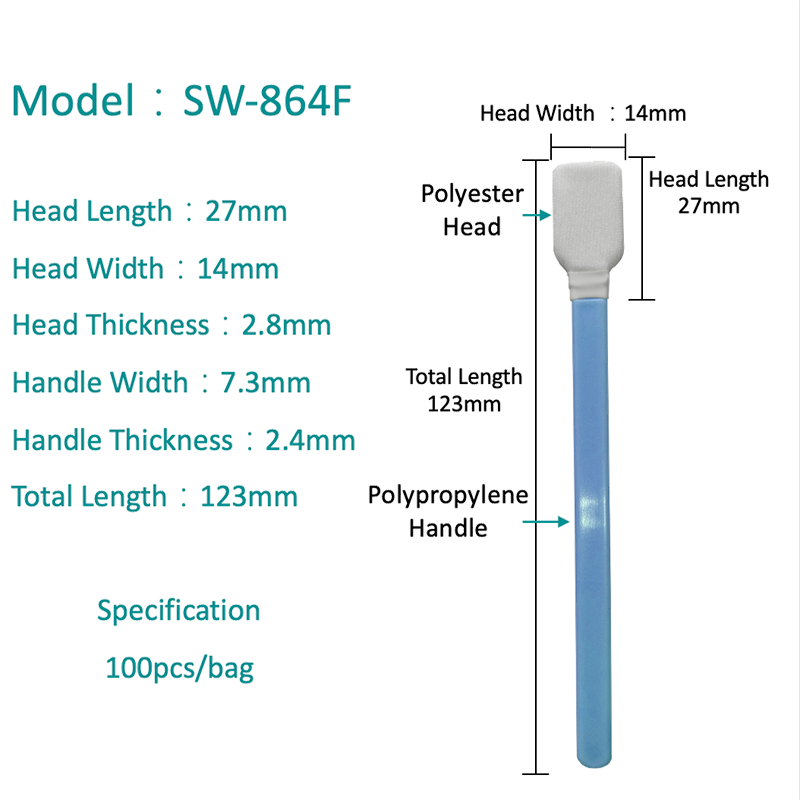

Tip Size and Density — Matching the Device or Surface

Not all foam tip swabs are created equal: tip size, shape, and foam density vary depending on intended use. For instance, cleaning a large port or connector might benefit from a thicker, denser tip, while precision cleaning of small crevices demands a slender, more flexible swab. Choosing appropriate tip specifications ensures you don’t damage components or miss hard‑to‑reach residue. Furthermore, foam density affects fluid uptake and release — impacting how much cleaning solvent you apply and how evenly it's distributed.

- Use thicker, dense‑foam swabs for larger surfaces or heavy residue removal.

- Use slim, flexible foam swabs for narrow spaces, delicate components, or precision tasks.

- Select foam density based on fluid loading needs (e.g. heavy cleaning vs light dust removal).

- Consider length of swab handle for reach and control.

Disposable vs Reusable — Pros & Cons

While many foam tip swabs are designed as single‑use disposables — particularly when sterility or hygiene matters — there are contexts in which cleaning and reusing swabs may seem tempting. However, reusing foam swabs can compromise performance: foam structure may degrade, absorb contaminants, or allow microbial growth, especially if moisture remains. For critical tasks like electronics maintenance or medical sampling, disposable usage preserves consistent results and reduces risk. Only when strict control of cleaning, drying, and storage is maintained might reuse be considered — though generally not recommended.

- Disposable swabs: maximal hygiene, consistent performance, no risk of contamination buildup.

- Reusable (rarely recommended): cost saving but risk of foam degradation, contamination, and unpredictable performance.

- If reusing, ensure thorough cleaning, drying, and possibly sterilization — but even then, performance may degrade.

- For sensitive tasks (electronics, medical, lab) — always prioritize disposable sterile foam tip swabs.

Common Misconceptions and Mistakes

“All Swabs Are the Same” Myth

A common misconception is that all swabs — cotton, foam, or otherwise — perform similarly. In reality, the choice of swab material dramatically affects cleaning efficacy, residue debris, and suitability for sensitive tasks. Believing all swabs are interchangeable can lead to fiber contamination, incomplete cleaning, or even damage. Recognizing the advantages of foam — especially for precise or clean‑room‑style tasks — is key to leveraging their full potential.

- Cotton swabs can leave lint and fibers — problematic for optics or electrical contacts.

- Foam tips reduce residue risk and provide consistent fluid control.

- Using foam swabs where cotton is used may improve results and reduce rework.

- Understanding swab material differences helps choose right tool for each task.

Over‑soaking with Liquid — Why Foam Tip Swabs Behave Differently

Because foam soaks up fluid differently than cotton, a common mistake is to treat foam tip swabs like cotton ones — saturating them heavily with cleaning solution. Over‑soaking can lead to excess liquid being deposited on sensitive surfaces, potentially causing damage (e.g. on electronics or optical components). Foam releases fluid more evenly, so a light dampening is typically enough. Appreciating this behavior helps avoid unintended side effects from misuse.

- Apply cleaning fluid sparingly — do not oversaturate the foam tip.

- Wipe off excess solvent before contact to prevent drips or pooling.

- Use gentle pressure — foam will release fluid gradually, avoiding flooding.

- Test on sacrificial surface first if uncertain about sensitivity of material.

FAQ

Is a foam tip swab sterile by default?

Not all foam tip swabs are sterile by default. If the swabs are intended for medical sample collection or wound care, it’s important to choose ones that are explicitly labeled as sterilized. Sterile foam tip swabs undergo sterilization processes (e.g. gamma sterilization or ethylene oxide) and are individually packaged to prevent contamination. For general cleaning tasks — like electronics maintenance or dust removal — non‑sterile foam tip swabs are usually sufficient. Always check packaging or product specification to confirm sterility before using in clinical or sensitive environments.

Can I safely clean electronics with foam tip swabs?

Yes — provided you use a foam tip swab for electronics cleaning correctly. Foam tip swabs are especially suited for cleaning connectors, ports, circuit boards, and sensors because of their non‑shedding, lint‑free tips and precise fluid control. The key is to dampen the swab lightly (not soak) with an appropriate cleaning solvent (e.g. isopropyl alcohol), avoid excessive moisture, and handle components gently. This approach minimizes risk of residue, short circuits, or corrosion. For best results, always allow the device to dry completely before powering on.

How does foam tip swab compare to cotton swab for cleaning delicate surfaces?

When comparing foam tip swabs to cotton swabs on delicate surfaces — such as optical lenses, sensors, or electronics — foam generally outperforms cotton. Foam’s structure avoids loose fibers, reduces residue risk, and offers better fluid control. Cotton swabs, in contrast, can leave lint, shed fibers, or compress under pressure — which may scratch surfaces or leave unwanted debris. For tasks requiring precision, cleanliness, and minimal risk of contamination, choosing a foam tip swab vs cotton swab cleaning effectiveness often leads to superior, more reliable outcomes.

What's the best way to store disposable foam tip swabs to keep them clean?

To maintain hygiene and performance of disposable foam tip swabs, proper storage is key. Ideally, store them in their original sealed packaging until use — especially if sterility is required. Keep swabs in a dry, dust‑free environment, away from moisture or direct sunlight. Once opened, avoid exposing swabs to contaminants, and use them promptly. For tasks like electronics cleaning or dust removal, storing swabs in a clean container or sealed bag helps prevent dust accumulation. Always discard after single use to avoid cross‑contamination and maintain consistency.

Are disposable foam tip swabs environmentally friendly?

Disposable foam tip swabs provide convenience and hygiene, but like many single‑use items, they raise environmental concerns. Because most foam tip swabs are made from synthetic foam materials, they are not biodegradable and contribute to plastic waste if disposed of improperly. For environmentally conscious users, this is a valid concern. If possible, choose swabs made from more eco‑friendly materials (when available), or limit use to tasks where precision and hygiene justify disposal. Additionally, consider proper waste management — discarding swabs in appropriate waste streams rather than general litter.

English

English  中文简体

中文简体