HOME / NEWS / Industry News / Why choose V-Shape Lens Microfiber Swab to effectively prevent dust from reattaching to the lens?

In the photography industry, lens cleaning has always been a crucial topic. Dust, fingerprints or stains on the lens surface often affect the shooting quality and may even cause irreversible damage to the lens. However, how to keep the lens clean for a long time and prevent dust from reattaching is a challenge faced by many photographers and image enthusiasts. Although traditional cleaning cloths can temporarily clean the lens, they often generate static electricity during use, causing the lens surface to be quickly re-contaminated by dust after cleaning. With the development of technology, V-Shape Lens Microfiber Swab has successfully solved this problem with its anti-static properties.

1. Static electricity problem of traditional cleaning cloths

During the cleaning process, traditional cleaning cloths often generate static electricity due to friction with the lens surface. These static electricity causes the cleaning cloth to attract dust in the air, resulting in fine dust particles still on the lens surface after cleaning. This not only affects the cleaning effect of the lens, but also increases the chance of the lens surface being contaminated again. The reattachment of dust means that users need to clean the lens more frequently, which increases the complexity and time cost of cleaning work.

In this case, the cleaning effect and durability of traditional cleaning cloths will be limited, and users will constantly face the problem of repeated dust contamination on the lens surface. Therefore, how to solve the static electricity problem and prevent dust from reattaching becomes the key to improving the cleaning effect.

2. Antistatic Advantages of V-Shape Lens Microfiber Swab

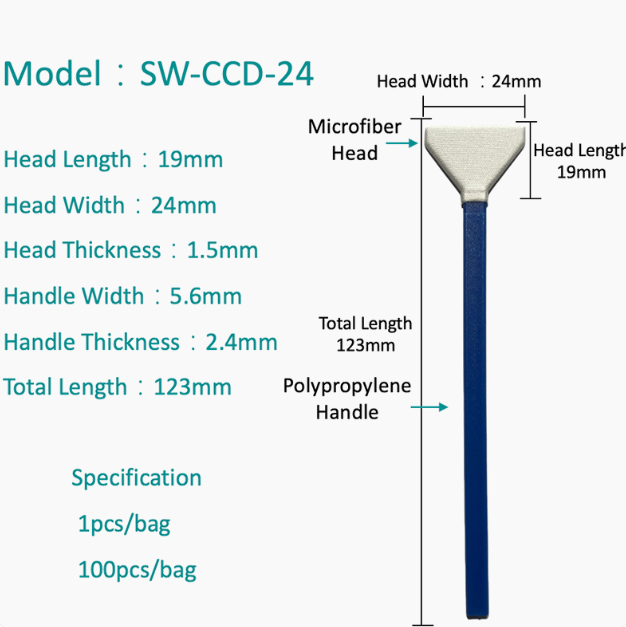

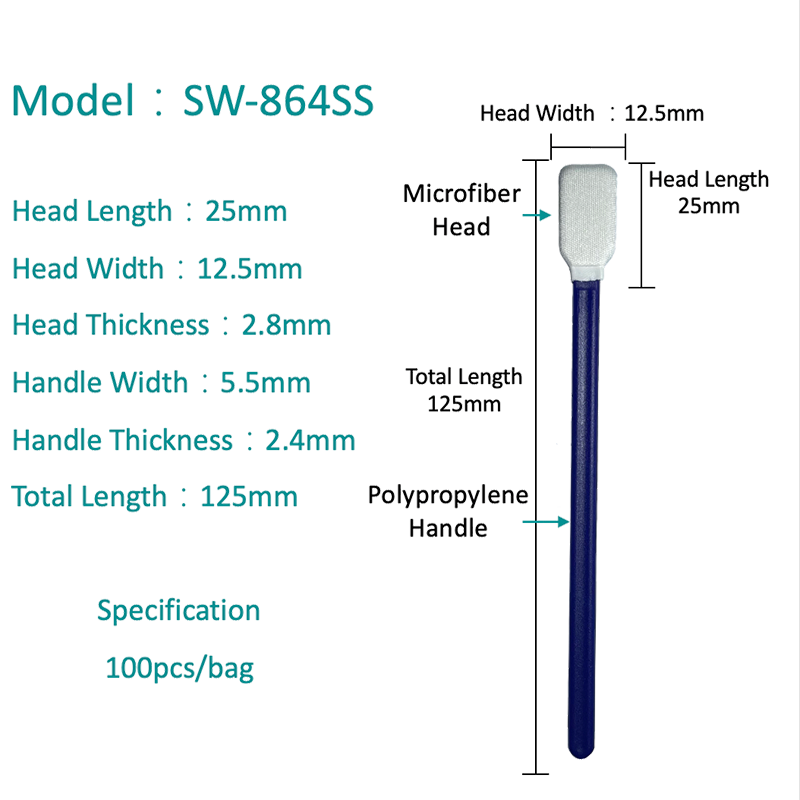

Unlike traditional cleaning cloths, V-Shape Lens Microfiber Swab uses advanced microfiber material, which has natural antistatic properties. The fine structure of microfibers can not only effectively remove dust, fingerprints and stains, but also reduce static electricity generated during friction, preventing dust and impurities from reattaching to the lens surface. This makes V-Shape Lens Microfiber Swab show unique advantages when cleaning lenses.

Because the microfiber material itself has an extremely low coefficient of friction, the static electricity generated during the cleaning process is significantly reduced, making the lens surface cleaner and smoother. This antistatic property ensures that the lens is not easily contaminated by dust in the air after cleaning, thereby extending the duration of the cleaning effect.

3. Efficient cleaning: more thorough and long-lasting

V-Shape Lens Microfiber Swab not only avoids dust adhesion, but also has strong adsorption capacity. Microfiber materials can efficiently capture stains, dust and fingerprints without spreading these impurities to other parts of the lens. This strong adsorption ensures that the lens surface is clean and traceless after cleaning, and users do not have to worry about needing to clean again due to incomplete cleaning.

In addition, the soft nature of the microfiber itself prevents it from leaving fiber residue on the lens surface, ensuring that the lens surface is smooth as new. This efficient cleaning method allows the lens to remain clean for a long time, greatly reducing the need for frequent cleaning and saving cleaning time and energy.

4. Reduce cleaning frequency: extend the life of the lens

Traditional cleaning cloths often lead to a gradual decline in cleaning effect after frequent use, and users need to constantly replace or wash the cleaning cloth. V-Shape Lens Microfiber Swab, with its superior antistatic properties and efficient dust removal ability, can reduce the number of cleaning times, thereby reducing lens wear. Improper or frequent cleaning over a long period of time may cause certain damage to the lens surface, but the design of the V-Shape Lens Microfiber Swab avoids this problem.

The possibility of static electricity attracting dust is reduced, and users do not need to wipe the lens repeatedly, which greatly reduces the damage caused by friction during the cleaning process. The lens can maintain a longer service life and the image quality remains consistent.

5. A new standard for lens cleaning

The anti-static properties of the V-Shape Lens Microfiber Swab represent a new standard for modern lens cleaning. Compared with traditional cleaning cloths, the V-Shape Lens Microfiber Swab can provide a more thorough cleaning effect during the cleaning process while keeping the lens surface clean and smooth. Solving the static electricity problem not only improves cleaning efficiency, but also enhances the protection function of the lens.

In addition, the choice of cleaning tools is crucial for every photographer. As an important part of photographic equipment, the lens needs to be fully protected and maintained. The design concept of the V-Shape Lens Microfiber Swab not only focuses on the cleaning effect, but also focuses on the long-term use needs of the lens. By reducing unnecessary friction and static cling during the cleaning process, the V-Shape Lens Microfiber Swab provides photographers with a more efficient and safer cleaning solution.

English

English  中文简体

中文简体