HOME / NEWS / Industry News / In-Depth Safety Analysis of Sensor Swabs: Can They Really Not Scratch Your Sensor?

Understanding the Sensor Swab and Its Purpose

For any photographer, the moment a speck of dust appears on an image is a moment of frustration. This often leads to the daunting task of camera sensor cleaning, a procedure that fills many with anxiety. At the heart of this cleaning process is the sensor swab, a tool designed specifically for this delicate job. A sensor swab is a lint-free, typically plastic wand tipped with a precise, non-abrasive material that is used in conjunction with a specialized cleaning fluid to physically remove contaminants from the camera sensor's filter. The primary goal is to eliminate dust, oil, and other particles without leaving behind any residue or, most importantly, causing any micro-scratches or damage to the ultra-sensitive sensor surface. The very design of the swab is intended to minimize contact pressure and maximize the safe removal of debris. However, the question that lingers in the minds of many enthusiasts and professionals alike is whether this tool, designed for protection, can inadvertently become an agent of harm. This analysis delves deep into the mechanics, materials, and methods to answer that pressing question.

Key Factors That Determine a Sensor Swab's Safety

The safety of a sensor swab is not determined by a single feature but by a combination of critical factors that work in concert to protect your valuable camera sensor. Understanding these elements is crucial for any photographer looking to make an informed decision about their cleaning routine.

Material Composition and Purity

The material from which the swab tip is constructed is arguably the most important factor in preventing scratches. The ideal material must be exceptionally soft, lint-free, and completely free of any embedded abrasive particles. Most high-quality swabs are made from high-purity polymers or specialized non-woven fabrics that are manufactured in ultra-clean environments. The purity of the material ensures that there are no hard contaminants within the swab itself that could act like sandpaper against the sensor's filter. Furthermore, the material must have the correct texture and absorbency to effectively hold the cleaning fluid and lift particles away, rather than grinding them across the surface. A lower-quality material might feel soft to the touch but could contain microscopic impurities that pose a significant scratching risk.

Structural Design and Edge Profile

The physical design of the swab plays a pivotal role in its safe application. A well-designed sensor swab features a precise width that matches common sensor formats, ensuring full coverage without excessive overhang that could lead to uneven pressure. The edges of the swab tip are particularly critical; they must be seamlessly bonded and have a rounded, soft profile. Sharp or poorly finished edges can create concentrated pressure points that dramatically increase the risk of scratching. The swab's handle or wand is also designed to be rigid enough for control but with a slight flexibility to prevent the user from applying excessive force unintentionally. The overall architecture is engineered for a single, smooth, and controlled pass, which is the recommended technique for effective and safe cleaning.

The Role of Cleaning Fluid

A sensor swab is almost always used with a specialized cleaning fluid, and the interaction between the two is vital for safety. The fluid serves multiple purposes: it dissolves stubborn contaminants like oils from fingerprints, it lubricates the surface to reduce friction during the swipe, and it helps to suspend the dislodged particles so they are lifted away. Using a swab dry on a sensor is highly discouraged, as it can create a high-friction environment where dust particles can drag and scratch the surface. The quality and formulation of the fluid are essential; it must be pure, fast-evaporating, and leave absolutely zero residue. An improper fluid can leave a film on the sensor or, in worst-case scenarios, react with the sensor's filter coating, leading to permanent damage.

Addressing Common Concerns and Myths

The world of sensor cleaning is rife with misinformation and fear. Let's tackle some of the most prevalent concerns head-on and separate fact from fiction.

The Myth of "Scratch-Proof" Swabs

No sensor swab can be truthfully labeled "scratch-proof." This is a dangerous misnomer. The correct term should be "non-abrasive" or "scratch-resistant." The potential for scratching always exists if the tool is misused, if it is contaminated after being removed from its sterile packaging, or if it is used with an incorrect technique. The safety of a swab is conditional upon proper use. A high-quality, non-abrasive swab used correctly on a sensor with loose dust presents an extremely low risk. However, using the same swab to scrub at a hardened, sticky contaminant can increase the risk significantly. Understanding that the swab is part of a system—which includes the fluid, the environment, and the user's technique—is key to managing expectations and ensuring safety.

Can a Swab Be Too Soft?

Some users wonder if a swab can be too soft to be effective. The logic is that an extremely soft material might not generate enough friction to dislodge stuck particles. In reality, the cleaning action is a combination of the fluid's solvent action and the very gentle physical lifting performed by the swab. A swab that is too stiff is far more dangerous than one that is very soft. The primary risk of an overly soft swab is not scratching, but potential linting or a failure to remove all debris in a single pass, potentially necessitating another cleaning cycle. The engineering goal is to find the perfect balance of softness for safety and structural integrity for effective particle removal.

Evaluating the Scratch Risk: A Comparative Analysis

To truly understand the safety profile of sensor swabs, it is helpful to compare them against other common sensor cleaning methods. The risk of scratching is present in any method that involves physical contact with the sensor, but the degree of risk varies dramatically.

The following table provides a comparative analysis of the scratch risk associated with sensor swabs versus other popular cleaning techniques. It is important to note that these risks are highly dependent on user skill and the quality of the tools used.

| Cleaning Method | Scratch Risk Level | Primary Risk Factor | User Skill Required |

|---|---|---|---|

| Sensor Swab (Dry) | Very High | High friction and dragging of abrasive particles. | Low (but method is not recommended) |

| Sensor Swab (With Fluid) | Low to Very Low | User error (angle, pressure, contaminated swab). | Medium to High |

| Air Blowers / Dust Blowers | Very Low | Impurities in the air or a contaminated blower tip. | Low |

| Brush Systems (Static) | Low | Bristles becoming contaminated with hard debris. | Low to Medium |

| Adhesive-Based Lifters | Low | Improper angle during application or removal. | Medium |

As the table illustrates, a sensor swab used with the proper fluid presents a low to very low scratch risk when compared to using a dry swab. Its risk is comparable to or lower than other physical contact methods like brush systems, largely because the fluid provides crucial lubrication and particle suspension. The primary differentiator for the swab is the higher degree of user skill required to execute the single, confident stroke correctly. This analysis shows that the perceived high risk of swabs is often overstated, especially when compared to the very real but often overlooked risk of contaminating a static brush.

Best Practices for Absolutely Safe Sensor Swab Use

Minimizing risk is the name of the game. Adhering to a strict protocol can make the difference between a perfectly clean sensor and a costly mistake. For those searching for the best way to clean camera sensor at home, following these best practices is non-negotiable.

- Prepare a Clean Environment: Perform the cleaning in a room with minimal air circulation, away from vents and doors. A bathroom after a shower can sometimes be ideal due to the settled dust. Have all your tools—swab, fluid, blower—unpacked and within easy reach.

- Initial Dry Removal: Before even touching a swab, use a rocket blower to dislodge any loose dust. This is the first and most crucial step in the proper sensor cleaning technique step by step. Point the camera mount down so the dust falls out, not deeper in.

- Inspect and Confirm the Need for Wet Cleaning: Use a sensor loupe to inspect the sensor after blowing. Only proceed with a swab if you confirm the presence of sticky residues or particles that the blower could not remove.

- Apply the Fluid Correctly: Apply the recommended number of drops of sensor cleaning fluid onto the swab's pad. Do not oversaturate. Wait a moment for the fluid to fully absorb into the material. This ensures an even application and prevents pooling on the sensor.

- Execute the Swipe with Confidence: This is the core of the how to use a sensor swab without scratching procedure. Place the swab at one end of the sensor, press down gently until you feel slight resistance, and in one continuous and smooth motion, drag the swab across the entire sensor surface. Do not stop, do not go back, and do not apply excessive pressure. Lift the swab straight off at the other end.

- Dispose of the Swab: Sensor swabs are designed for a single use. Using a swab for a second pass will re-deposit the grime you just collected. This is a key part of sensor swab single use vs reusable knowledge. Always use a fresh swab for each pass.

- Final Inspection: After the swipe, use the blower again to evaporate any residual fluid and then inspect the sensor with the loupe. If spots remain, you must repeat the entire process with a brand-new swab.

Selecting the Right Tool for Your Sensor

Not all sensor swabs are created equal, and using the wrong size is a common source of problems. The question of what size sensor swab do I need is fundamental to a safe cleaning experience.

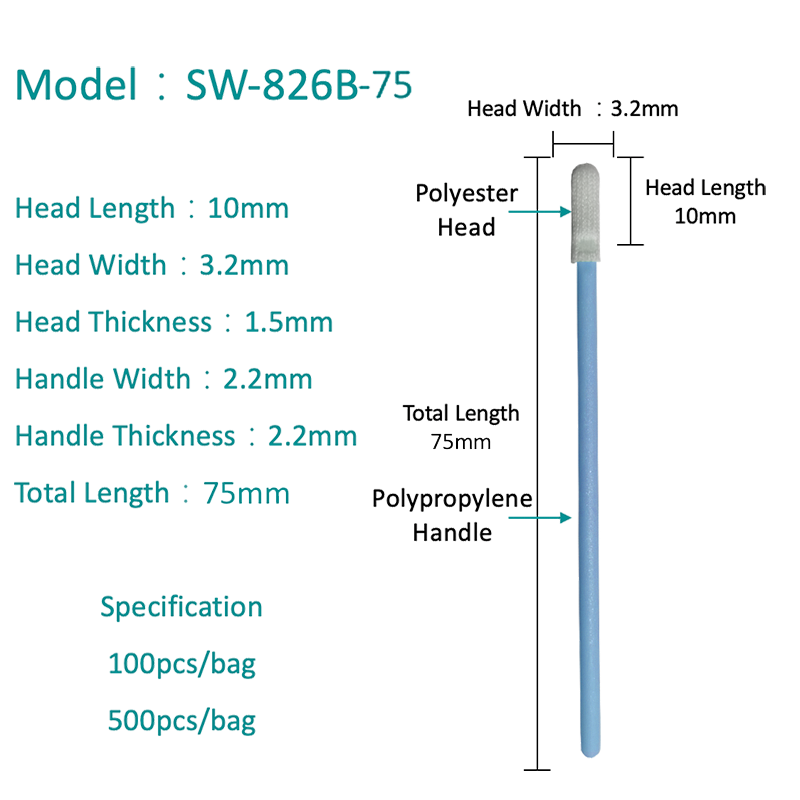

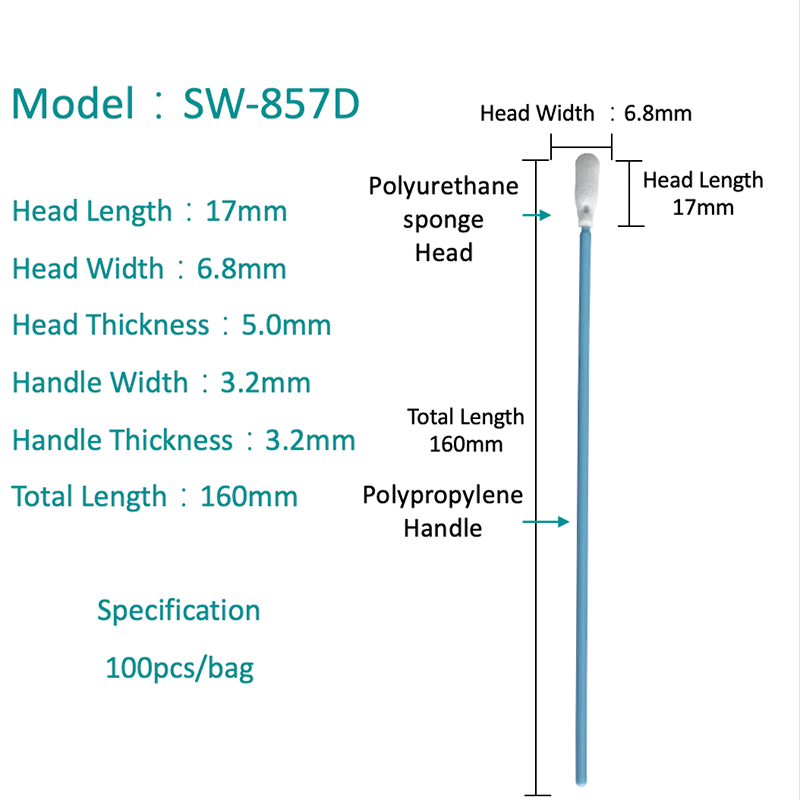

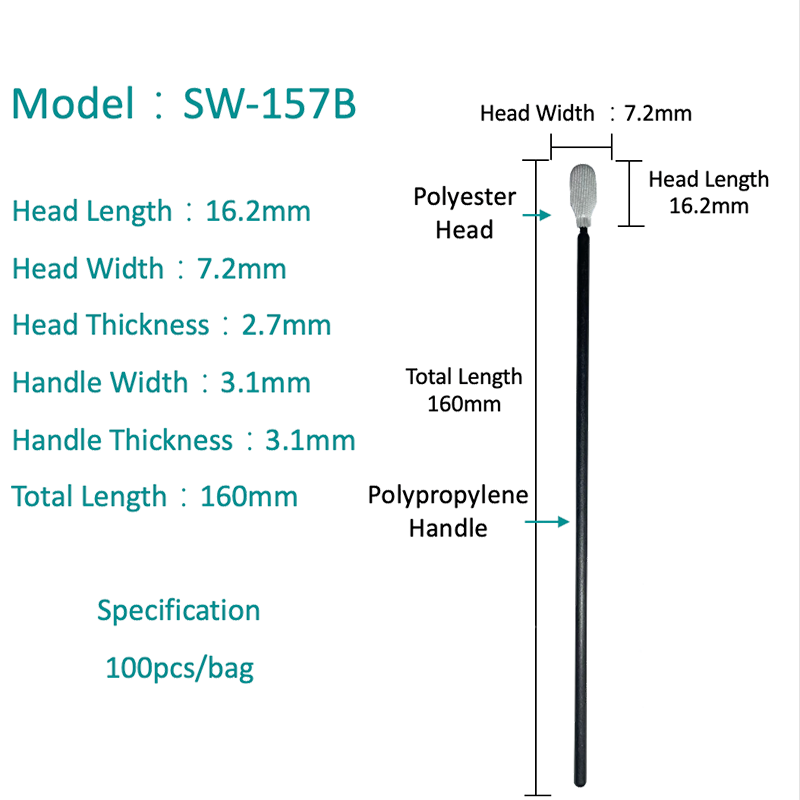

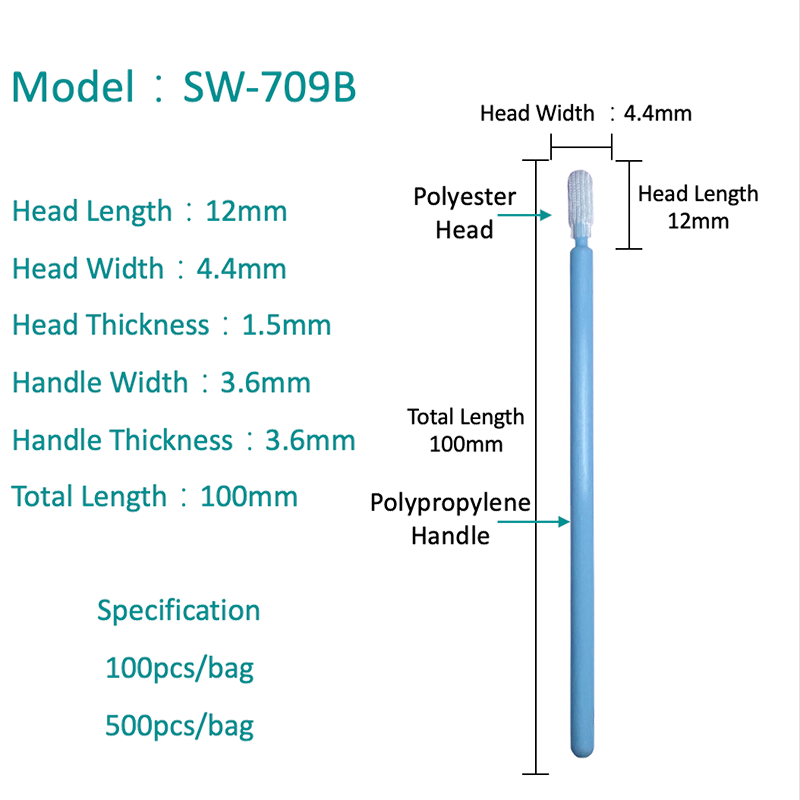

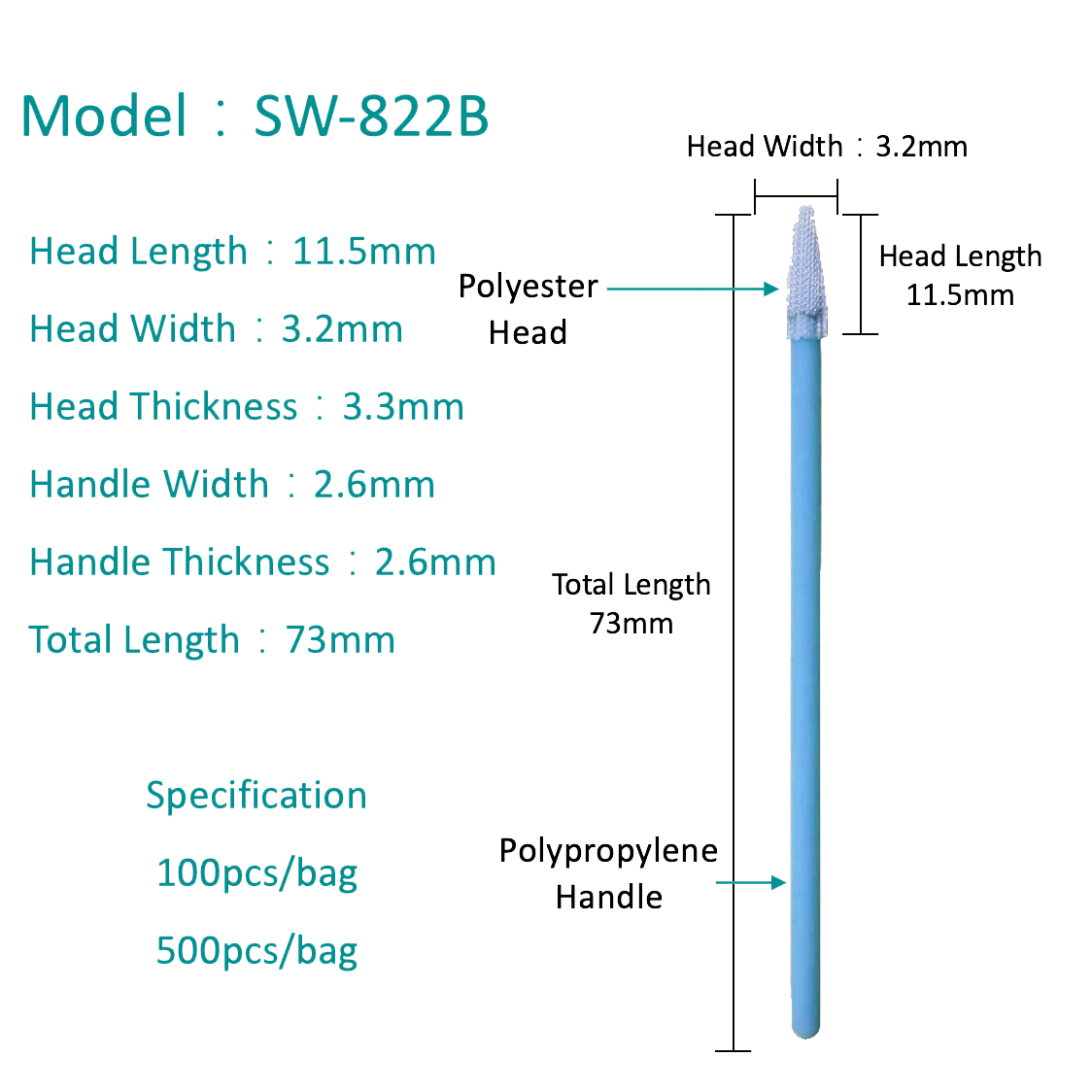

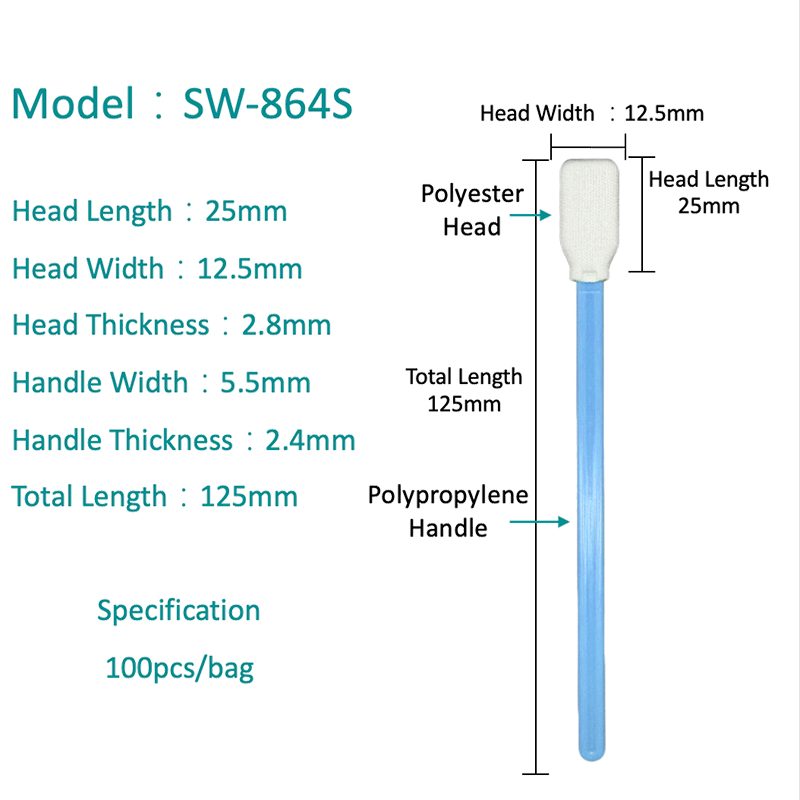

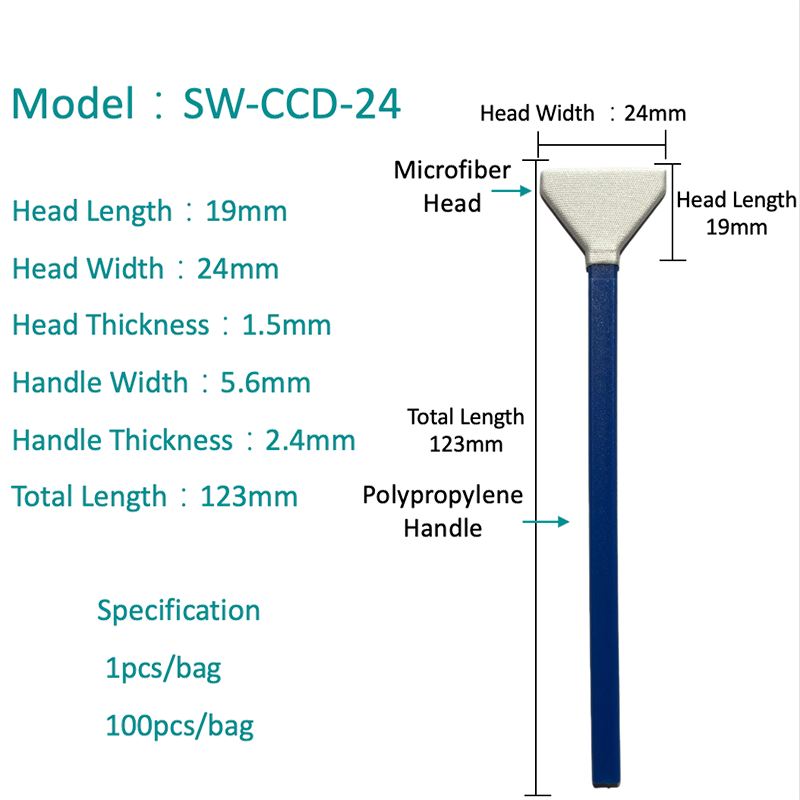

Camera sensors come in different sizes, and so do sensor swabs. The most common sizes correspond to full-frame (35mm), APS-C, and Micro Four Thirds sensors. Using a swab that is too narrow for your sensor will require multiple overlapping passes, dramatically increasing the risk of leaving streaks and re-contaminating the surface. Conversely, a swab that is too wide for the sensor well will cause the edges to buckle and apply uneven pressure, creating a significant scratching hazard. To determine the correct size, you must know the exact dimensions of your camera's sensor. This information can be found in your camera's manual or on the manufacturer's website. Generally, a full-frame sensor requires the largest swab (typically around 24mm), while APS-C sensors use a medium size (around 15mm), and Micro Four Thirds sensors use a smaller size. Investing in the correctly sized swab is as important as investing in a high-quality one.

The Verdict on Sensor Swab Safety

So, can sensor swabs really not scratch your sensor? The comprehensive answer is that when high-quality, non-abrasive swabs are used correctly as part of a disciplined cleaning protocol, the risk of scratching is exceptionally low. The tool itself, when designed and manufactured to high standards, is not the primary danger; the greatest risks stem from user error, improper technique, and a contaminated cleaning environment. The fear of scratching often paralyzes photographers into inaction, leading to a consistently dirty sensor that affects image quality. By understanding the engineering behind the swab, respecting the process, and adhering to the best practices outlined—including the critical understanding that they are for sensor swab single use vs reusable scenarios—photographers can confidently maintain their equipment. The sensor swab remains the most effective method for removing stubborn contaminants, and its safe use is well within the reach of any careful and informed individual.

English

English  中文简体

中文简体